Collector inner core of space traveling wave tube and production technology of collector inner core

A manufacturing process and collector technology, which is applied in the field of microwave vacuum electronic devices, can solve the problems of reducing the collector efficiency of space traveling wave tubes, affecting the performance of traveling wave tube products, and affecting the development of space traveling wave tubes, so as to improve the electron collection efficiency , light weight and satisfactory size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

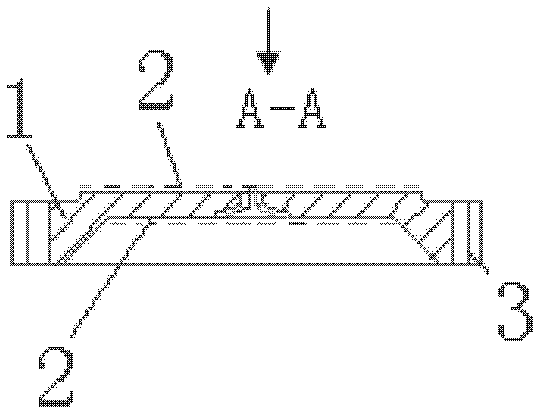

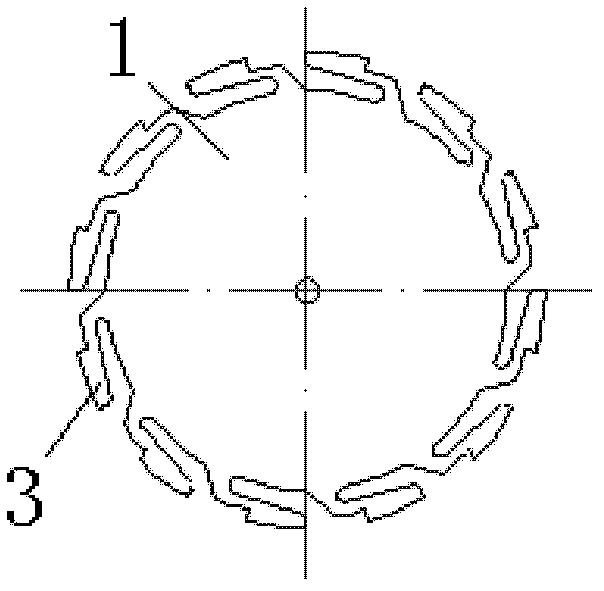

[0035] Such as figure 1 and figure 2 As shown, the collector core of the space traveling wave tube includes an oxygen-free copper core body 1 on which a black chromium layer 2 is arranged.

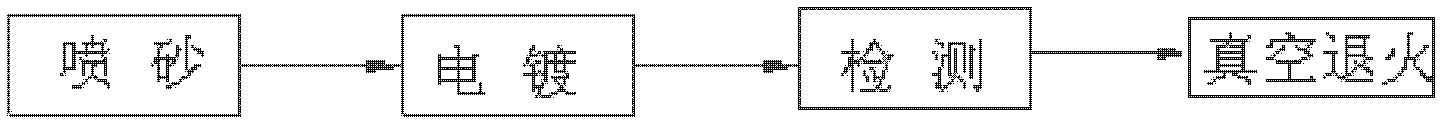

[0036] The thermal stability of the black chrome layer 2 is high, and the subsequent welding of the collector assembly is carried out with the electroplated collector core, and the temperature rises to 780°C, and the appearance does not change after taking it out; properties are better than oxygen-free copper, and the secondary electron emission coefficient of oxygen-free copper is 1.3-1.4, which is about 2 times of the secondary electron emission coefficient of black chromium layer 2; The black chrome layer 2 and the oxygen-free copper inner core body 1 can greatly improve the ability to resist elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com