Optical anode slurry for dye-sensitized solar cell and preparation method thereof as well as optical anode for dye-sensitized solar cell and dye-sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the field of solar cell manufacturing, can solve the problems of increasing photoelectric conversion rate, low dye adsorption rate, hindering electron transmission, etc., and achieve high photoelectric conversion rate, high photoelectric conversion rate, and uniform distribution of voids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

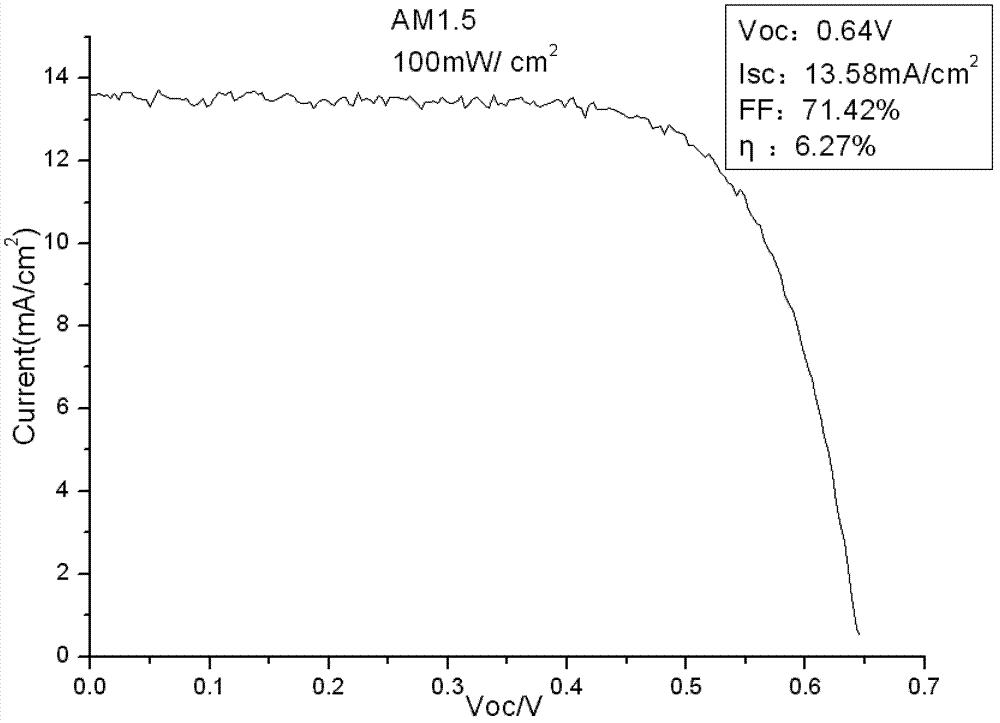

Embodiment 1

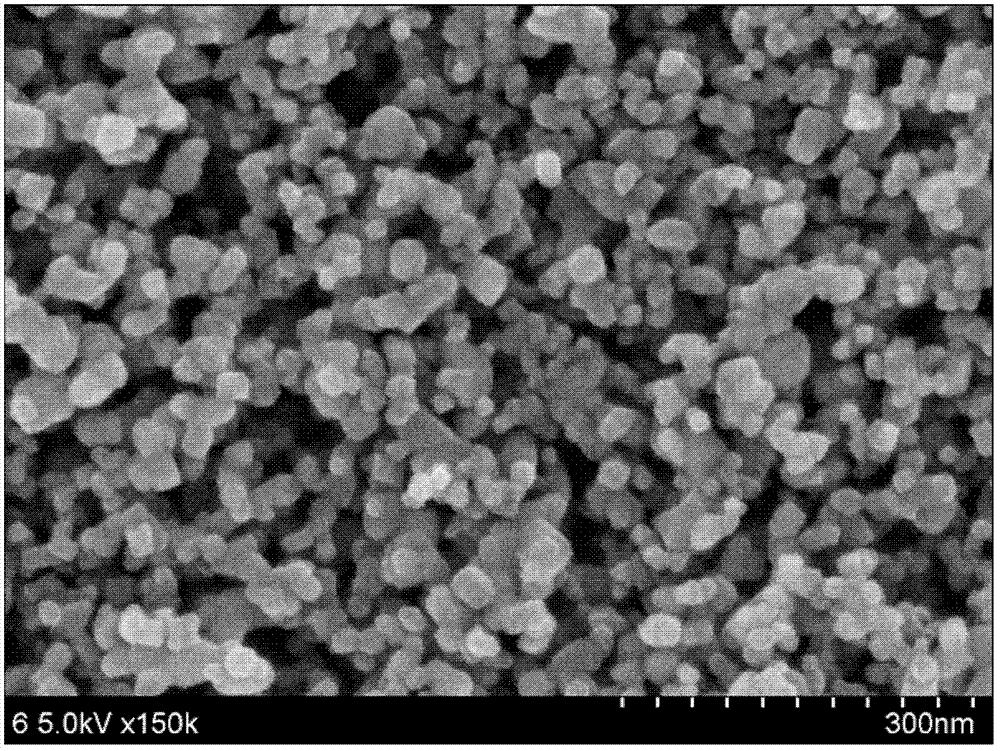

[0041] Weigh 34g of tetrabutyl titanate, add 6g of acetic acid into it, stir well to mix tetrabutyl titanate and acetic acid evenly, then add 170ml of water to it, hydrolyze for 1.5h at room temperature, tetrabutyl titanate is particularly easy Hydrolysis occurs, agglomeration occurs, and large particles of titanium dioxide are generated. Acetic acid can inhibit the hydrolysis of tetrabutyl titanate, slow down the hydrolysis reaction speed of tetrabutyl titanate, and generate uniformly dispersed hydrolyzate of small particles. Add 5ml of nitric acid to the hydrolyzate, nitric acid can make the particles smaller and more evenly dispersed. The hydrolyzate was put into a water bath at 80° C. and reacted for 2 hours to form a sol. Transfer the generated sol to a high-pressure reactor and react at 230°C for 24 hours. The product obtained by the hydrothermal reaction is washed centrifugally with water and dried at 70°C to obtain the desired powder. The particle size of the self-made...

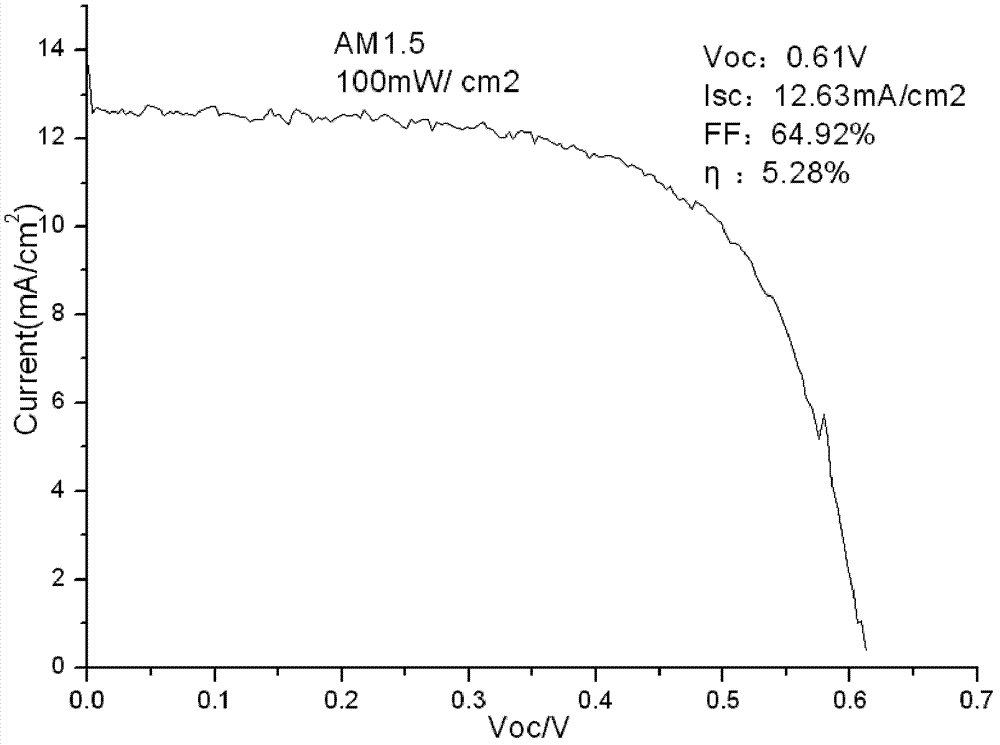

Embodiment 2

[0051] Weigh 28.8g of isopropyl titanate, add 5.16g of polyacrylic acid into it, stir well to mix the isopropyl titanate and polyacrylic acid evenly, then add 260ml of water into it, and hydrolyze for 4h at room temperature. Add 5ml of nitric acid to the hydrolyzate, nitric acid can make the particles smaller and more evenly dispersed. The hydrolyzate was put into a water bath at 100° C. and reacted for 5 hours to form a sol. Transfer the generated sol to a high-pressure reactor and react at 210°C for 36 hours. The product obtained by the hydrothermal reaction is washed centrifugally with water and dried at 70°C to obtain the desired powder. The particle size of the self-made titanium dioxide powder is 8~ 16nm, the specific surface area is 90m 2 / g.

[0052] Weigh 14g of P25 titanium dioxide powder nanocrystals and 6g of the small particle titanium dioxide powder nanocrystals self-made in the above reaction steps, grind and mix them evenly, and add 50ml of ethanol to the mix...

Embodiment 3

[0055] Weigh 29.4g of titanium ammonium lactate, add 90ml of water to it, and hydrolyze for 1 hour at room temperature. The hydrolyzate was put into a water bath at 90° C. and reacted for 1.5 h to form a sol. Transfer the generated sol to a high-pressure reactor, react at 220°C for 22 hours, wash the product obtained by the hydrothermal reaction with ethanol, and dry it at 70°C to obtain the desired powder. The particle size of the self-made titanium dioxide powder is 8~ 16nm, the specific surface area is 95m 2 / g.

[0056] Weigh 5.32g of P25 titanium dioxide powder nanocrystals and 7.98g of small particles of titanium dioxide powder nanocrystals made in the above reaction steps, grind and mix them evenly, and add 20ml of ethanol to the mixture as a dispersant. Weigh 4g of 200Pa.s ethyl cellulose as binder, weigh 36g of terpineol, mix the weighed ethyl cellulose with terpineol, dissolve ethyl cellulose into terpineol , stirred to form a certain viscosity organic vehicle. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com