Testing device for simulating equipment corrosion of continuous distillation industrial device

A technology for testing equipment and equipment corrosion, applied in measurement equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of insufficient understanding of the characteristics of vacuum distillation process, corrosion of oil refining equipment, and lack of light components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

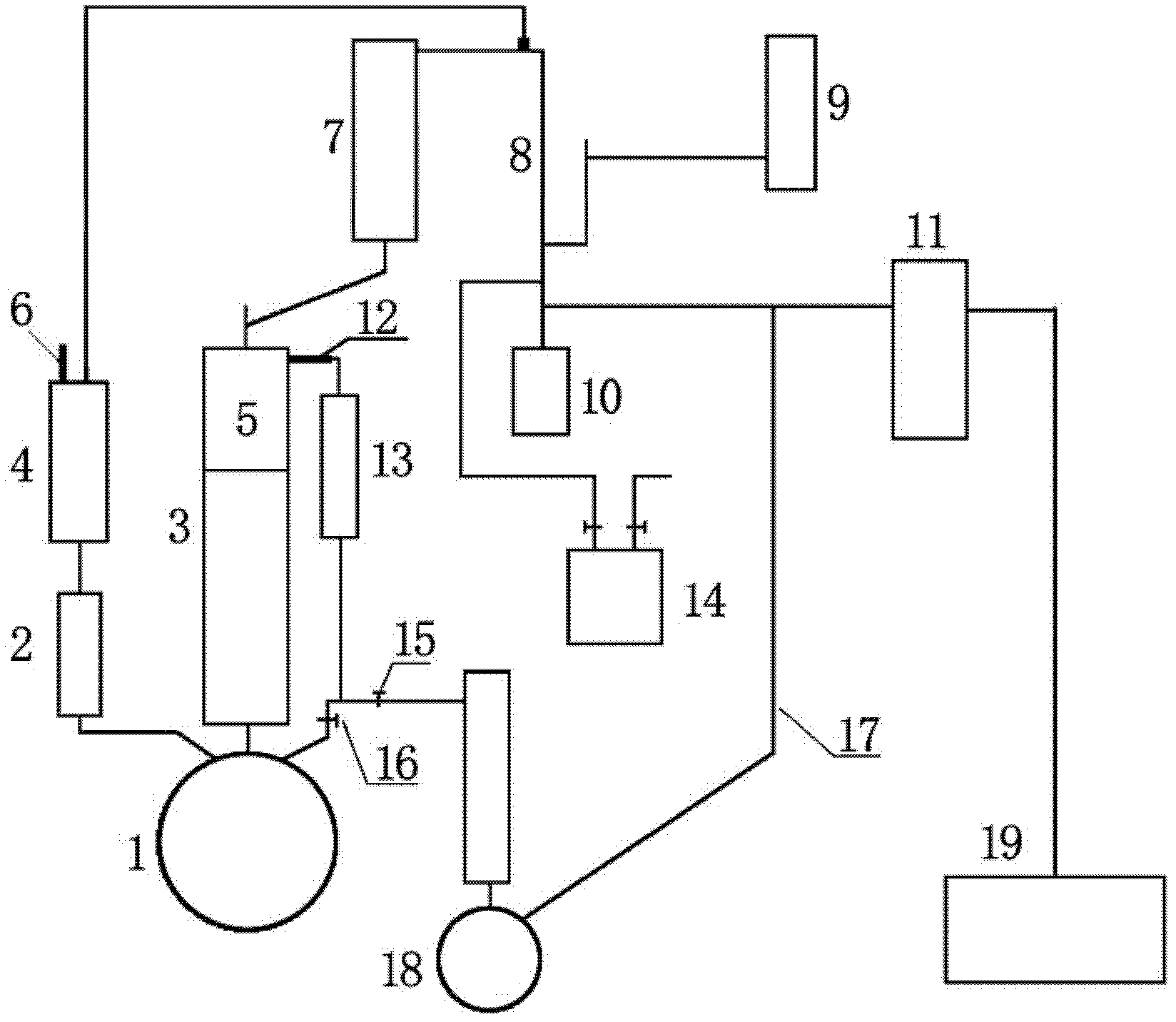

[0023] see figure 1 , the test device mainly includes continuous distillation system, pressure control system, corrosion sample system. The continuous distillation system includes a multi-necked flask 1, a main reactor 3, and a main condenser 7. The pressure control system includes a non-condensable gas receiving tank 10, a cold trap 11, and a vacuum pump 19. Sample hanging device for placing samples in phase and liquid phase. The multi-necked flask 1 is used to contain the medium used in the experiment, such as the crude oil after electric desalting or the bottom oil of the atmospheric distillation tower. There is an electric heater (not shown) conforming to the shape of the multi-necked flask 1 outside the multi-necked flask to heat the experimental medium in the flask. The main interface on the upper part of the multi-necked flask is connected with a cylindrical main reactor 3 made of glass. The upper end of the main reactor 3 is connected to a double-layer silver-plated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com