NMP pervaporation dehydration method

A technology of pervaporation and permeate, applied in the field of high-purity NMP production, can solve the problem that purification research needs to be further strengthened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

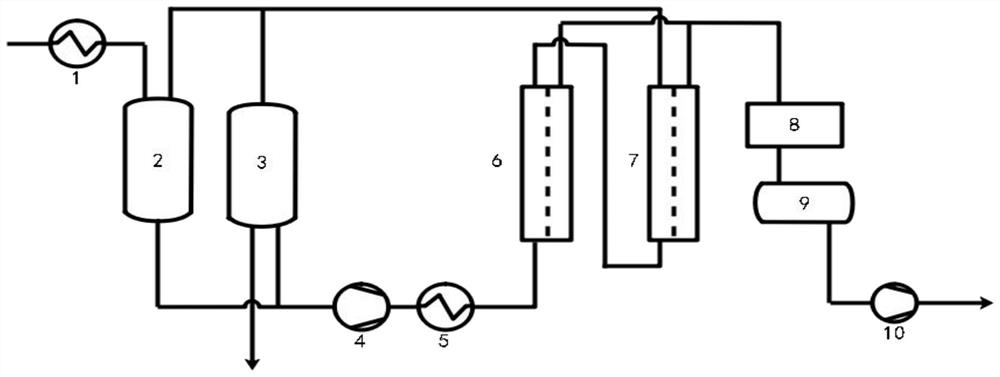

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] The invention provides a method for NMP pervaporation dehydration, comprising: preheating the NMP raw material containing water at a mass flow rate of 1200±100kg / batch and then entering the first storage tank; The permeate enters the permeate treatment unit; the retentate of the primary dehydration enters the second storage tank, and continues to be circulated to the membrane separation unit for secondary dehydration, and the retentate of the secondary dehydration enters the first storage tank. When it is detected that the retentate contains water When the rate meets the product requirements, the NMP product is mined. Wherein, in order to ensure product quality, in the above-mentioned method for NMP pervaporation dehydration of the present invention, the mass percentage of water in the water-containing NMP ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com