Hexagonal type barium titanate powder, producing method thereof, dielectric ceramic composition, electronic component, and producing method of electronic component

A hexagonal, barium titanate technology, applied in the direction of titanium compounds, ceramics, titanates, etc., can solve the problems of insufficient dielectric layers for electronic components, and achieve full reliability, high relative permittivity, insulation, etc. Excellent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0117]

[0118] First, as a raw material of barium titanate, BaCO 3 (specific surface area: 25m 2 / g) and TiO 2 (specific surface area: 50m 2 / g). In addition, as a raw material of the element M, La(OH) 3 (specific surface area: 10m 2 / g), as a raw material for Ga, prepare Ga 2 o 3 (specific surface area: 15m 2 / g).

[0119] Weigh these raw materials, so that the general formula (Ba 1-α m α ) A (Ti 1-β Ga β ) B o 3 α, β, and A / B in are the values shown in Table 1, respectively, and water and a dispersant were mixed together using a ball mill. The obtained mixed powder was treated under the following heat treatment conditions to prepare hexagonal barium titanate powder.

[0120] Heat treatment conditions are: heating rate: 200°C / hour, holding temperature: the temperature shown in Table 1, temperature holding time: 2 hours, cooling rate: 200°C / hour, atmospheric gas: reduction of nitrogen+hydrogen (3% by volume) sex atmosphere.

[0121] The obtained hexagona...

experiment example 2

[0142] In addition to using the oxides, carbonates, and hydroxides of the elements shown in Table 4 instead of La(OH) 3 Except for the raw material of element M, powder was produced in the same manner as in Experimental Example 1, and the specific surface area and X-ray diffraction measurement were performed. The results are shown in Tables 4-6.

[0143] Table 4

[0144]

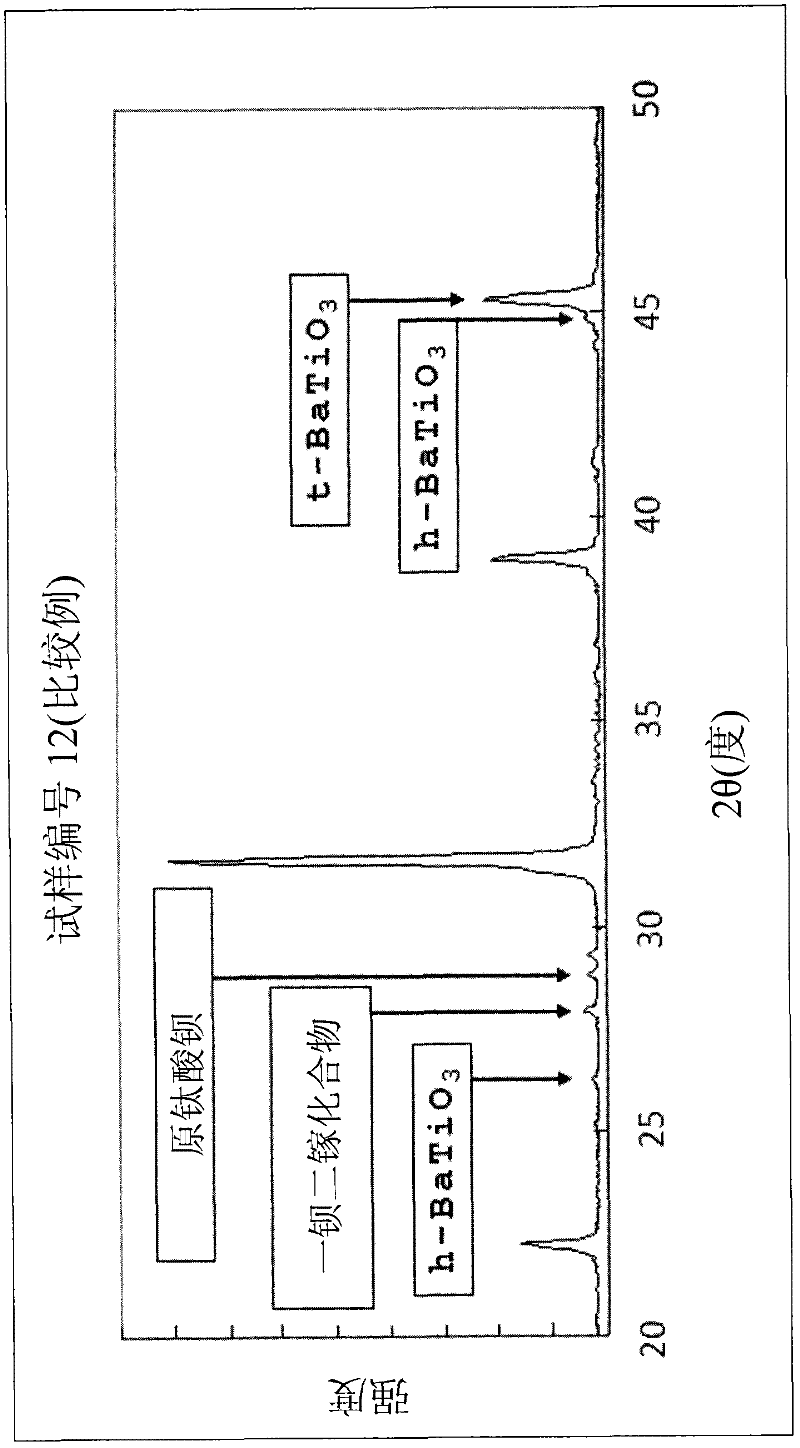

[0145] "Miscible phase" means that there are more than 2 phases in h-BT, t-BT, c-BT, barium orthotitanate / barium digallium compound

[0146] table 5

[0147]

[0148] Table 6

[0149]

[0150] From the above, it can be confirmed that the hexagonal barium titanate powder of the present invention contains hexagonal barium titanate as a main component and has a specific surface area of 2 m 2 / g or more, the particle size distribution is narrow.

experiment example 3

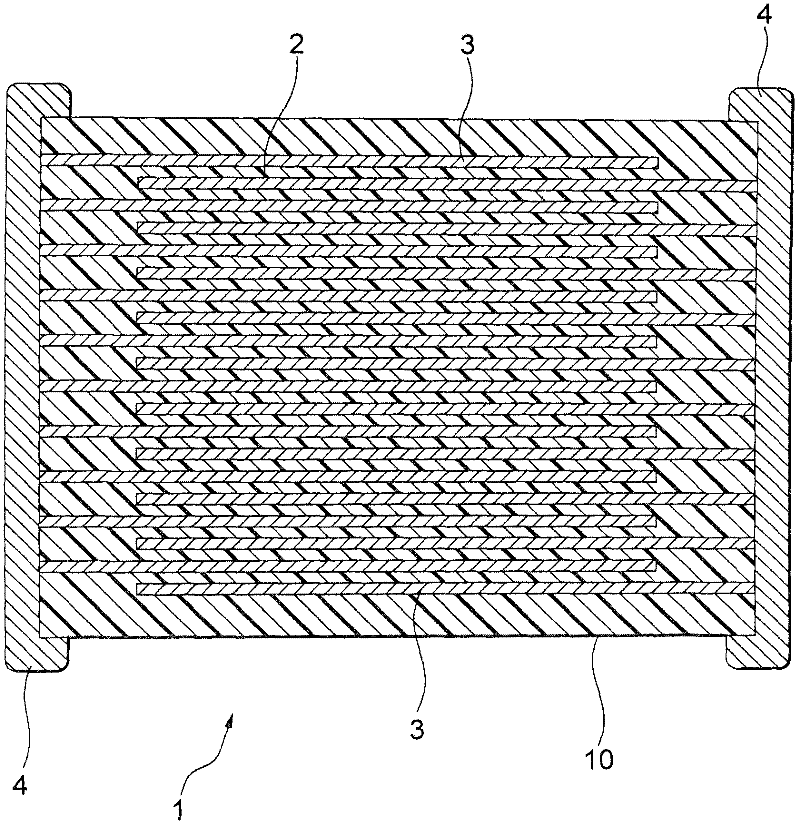

[0152]Dielectric powders (samples 1, 2, 5, 8 to 11, 14, 15, 17, 18, 25-34). To these dielectric powder samples: 100% by mass, polyvinyl alcohol aqueous solution: 10% by mass was added, followed by granulation and sieving. Then, the obtained granulated powder was molded under a pressure of 30 Pa to obtain a disk-shaped green body with a diameter of 12 mm and a thickness of about 1 mm.

[0153] Next, the obtained formed body was fired in an atmosphere of nitrogen + hydrogen (3% by volume) at 1300° C. for 2 hours to obtain a disk-shaped sintered body. Then, an indium gallium electrode was applied to the main surface of the obtained sintered body, followed by firing treatment to obtain a disc-shaped ceramic capacitor sample. The thickness of the dielectric layer 10 of the obtained capacitor sample was about 0.6 mm. Then, for each of the obtained capacitor samples (samples 1a, 2a, 5a, 8a to 11a, 14a, 15a, 17a, 18a, 25a to 34a), the "relative permittivity ε", "insulation resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com