Sealed and waterproof seabed heat-preservation pipe

A technology for thermal insulation pipes and thermal insulation layers, which is applied in the directions of thermal insulation, protection of pipelines through thermal insulation, and anti-corrosion/anti-rust protection of pipelines. The effect of good sealing and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

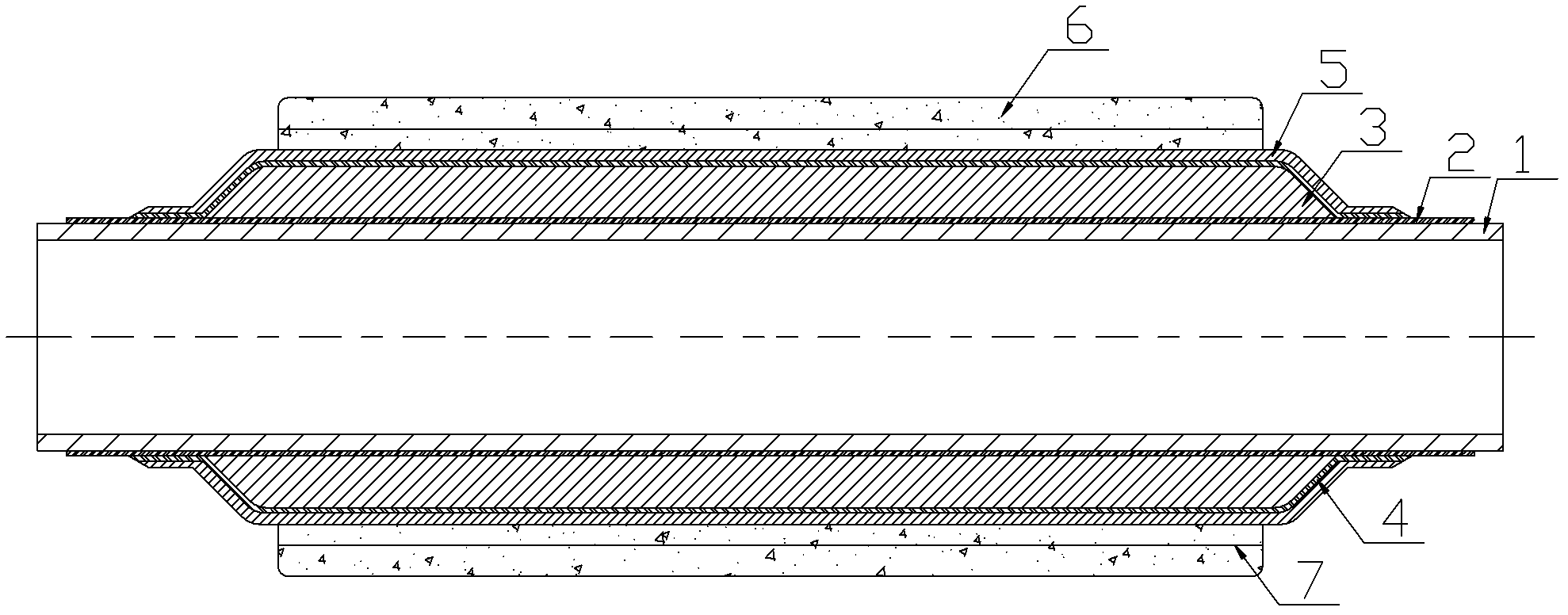

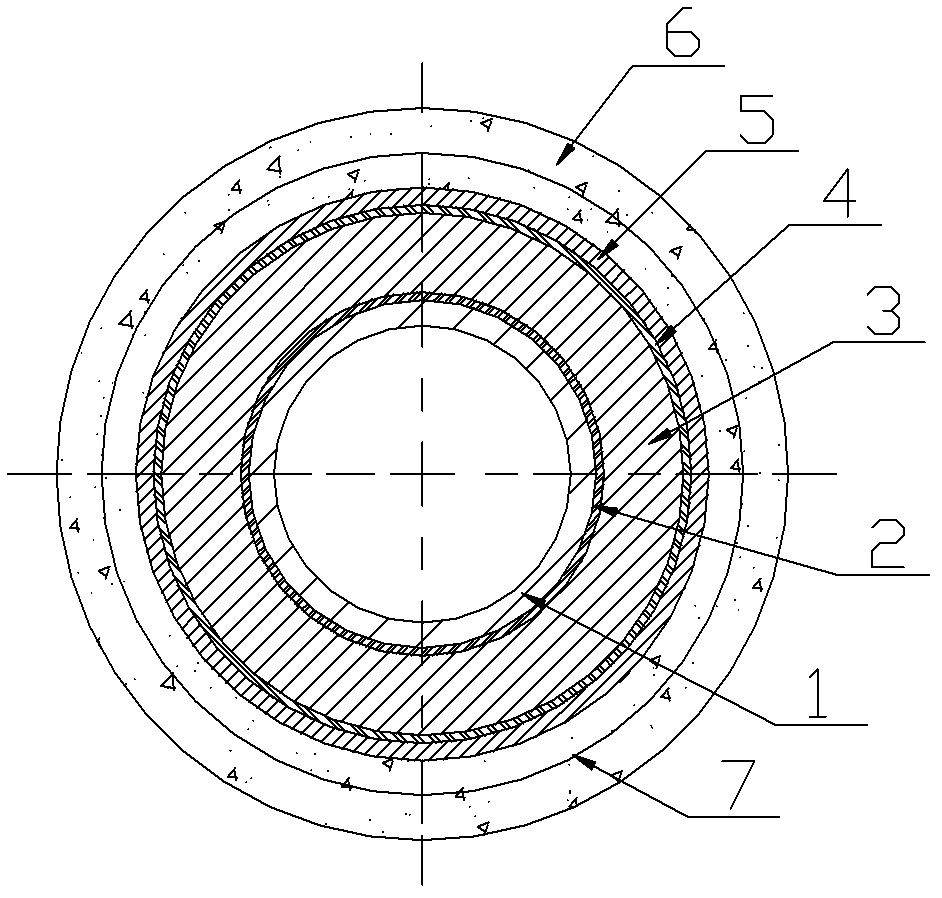

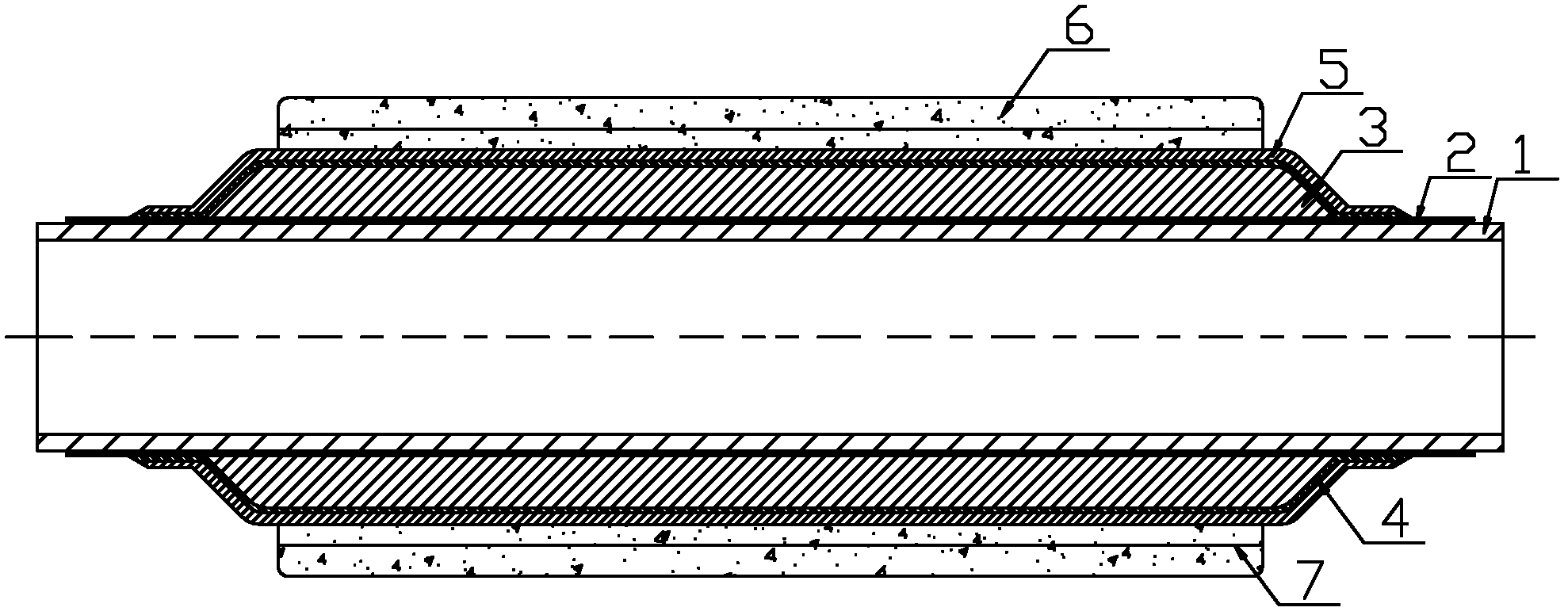

[0020] see Figure 1 ~ Figure 2 , a sealed and waterproof submarine insulation pipe, comprising a steel pipe 1, an anticorrosion layer 2 is provided on the outer surface of the steel pipe 1, an insulation layer 3 is provided on the outer surface of the anticorrosion layer 2, and a coating protective layer is bonded on the outer surface of the insulation layer, The coating protection layer is formed by polyurethane elastomer, and the polyurethane elastomer coating protection layer 5 is bonded to the insulation layer 3 and the anticorrosion layer 2 through the polyurethane primer. The anticorrosion layer 2 is overlapped to seal the heat preservation layer 3 on the steel pipe 1, and a weight layer 6 is provided on the outer surface of the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com