Coal mine gas fast solvent and application method thereof

A coal mine gas and fast solvent technology, which is applied in mining equipment, earthwork drilling, safety devices, etc., can solve problems such as water injection pipe fracturing, affecting progress, and inability to inject water, so as to ensure safe production and increase tunneling speed , the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

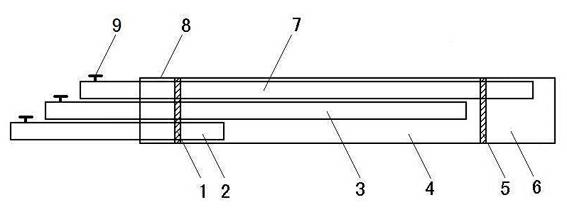

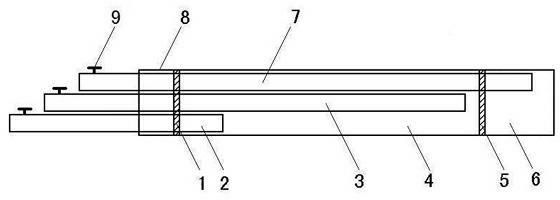

Image

Examples

example 1

[0054] Example 1: coal mine gas instant solvent, by weight, grain vinegar: edible yeast: baking powder: soda flour = 10000: 100: 1: 0.5. When making, mix the above-mentioned raw materials and get final product.

example 2

[0055] Example 2: coal mine gas instant solvent, by weight, grain vinegar: edible yeast: baking powder: soda flour = 10000:800:8:5. When making, mix the above-mentioned raw materials and get final product.

example 3

[0056] Example 3: coal mine gas instant solvent, by weight, grain vinegar: edible yeast: baking powder: soda flour = 10000: 200: 5: 0.5. When making, mix the above-mentioned raw materials and get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com