Layered top-controlling filling mining method for residual ores in deep hole in diskless area

A backfill mining method and deep hole technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., to achieve the effect of reducing column spacing, low ore loss rate, and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

[0022] The technical scheme of the mining method of the present invention is as follows:

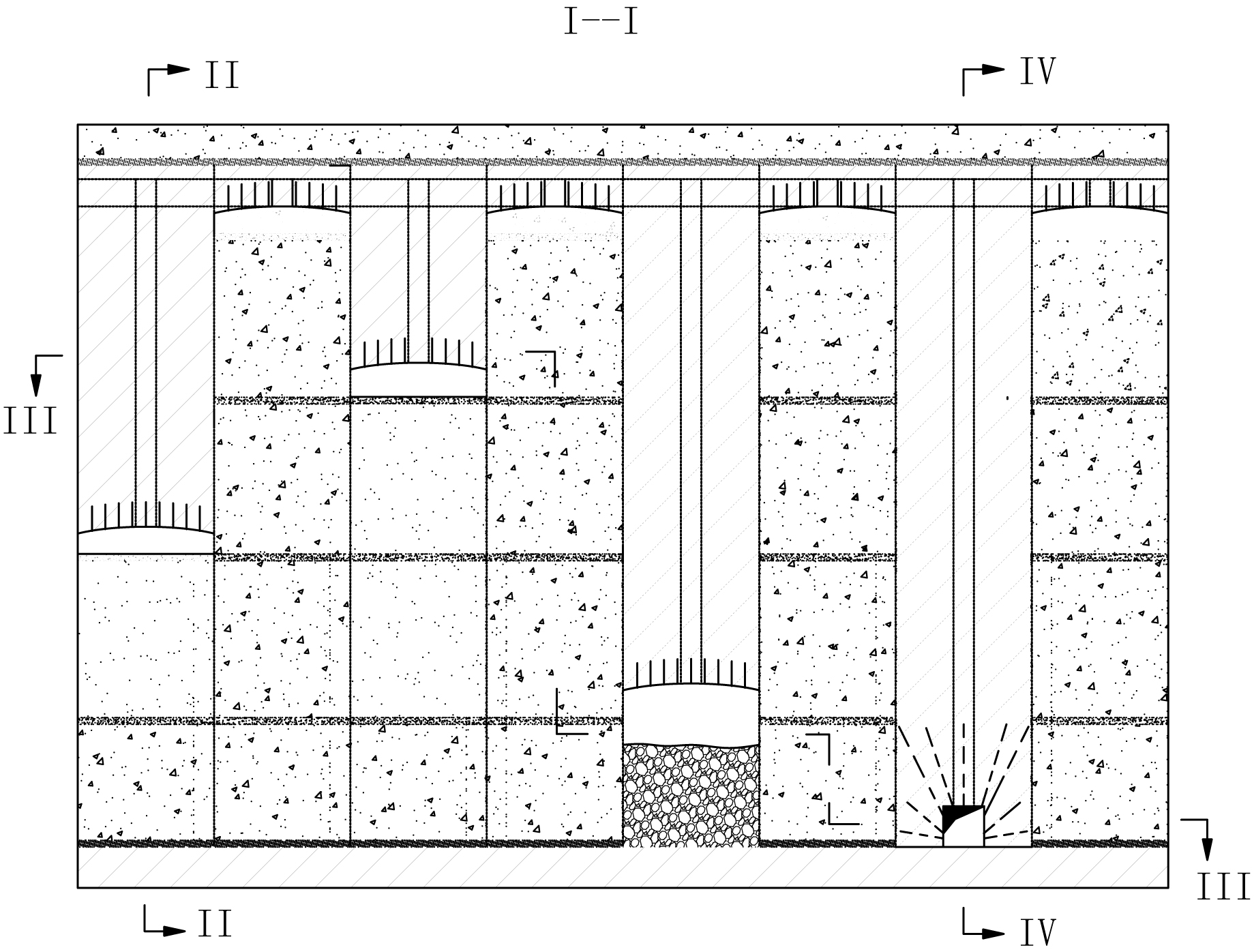

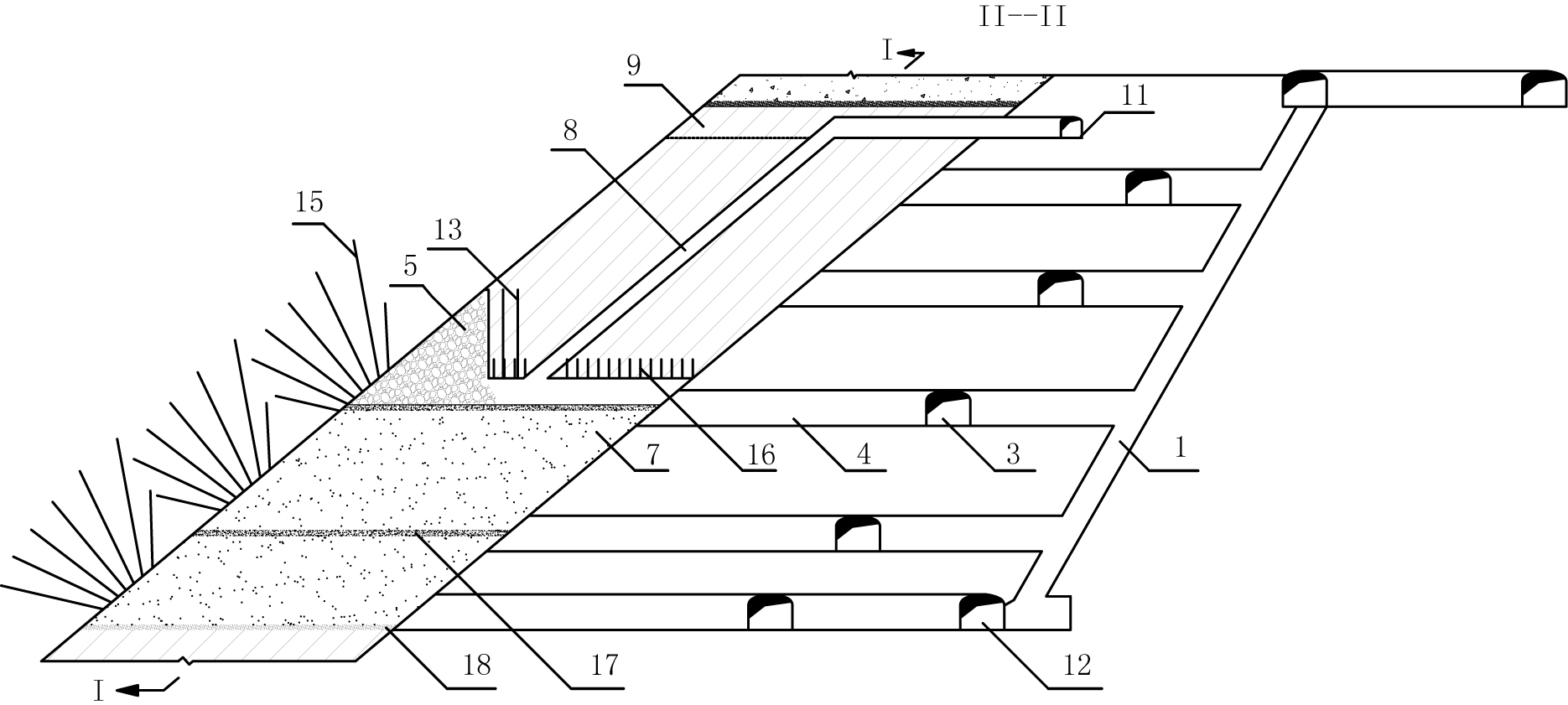

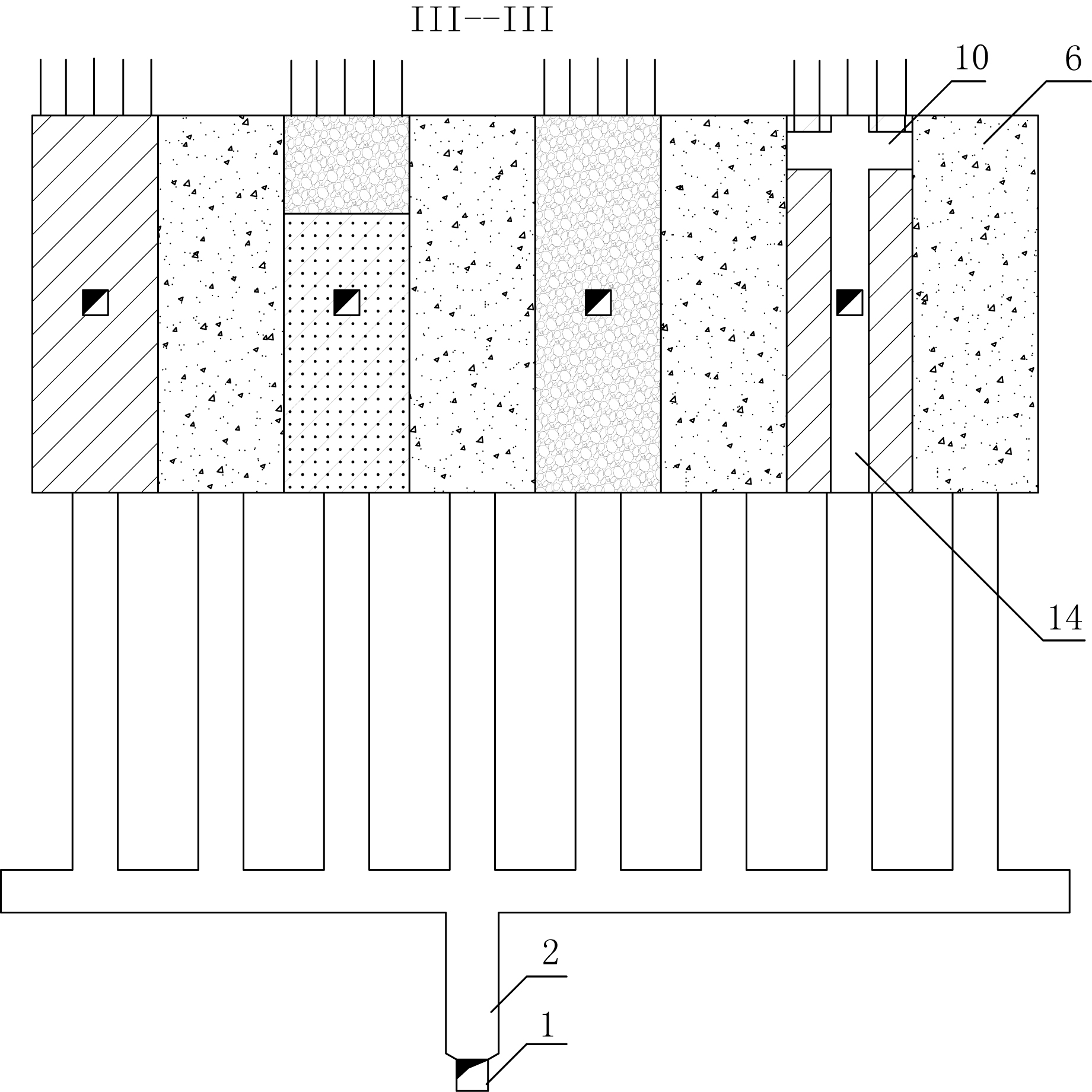

[0023] 1. Divide the ore block into ore houses and pillars arranged at intervals along the direction of the ore body. The width of the ore houses and pillars is 10m; the production is organized with 6~8 groups of ore houses and pillars as the mining unit. Panel, continuous mining along the strike, such as figure 1 .

[0024] 2. The height of the middle section of the mining is 50m, and the mining is from bottom to top. The method of non-track mining outside the footwall vein is adopted. The technical points are as follows: Parallel to the boundary of the footwall of the ore body, segmented roadways 3 are arranged, and each segmented roadway 3 is connected to the out-of-vein slope road through the ramp connecting channel, and the stope is segmented Connecting lane 4 connects the stope with each sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com