Goaf treatment method based on filling raises with surface barren rock

A technology for backfilling patios and gobs, which is applied in fields such as backfills, mining equipment, and earth-moving drilling, etc., can solve the problems of easy failure of the backfill system, complicated production process of backfill materials, and many mechanical equipment, etc., and can eliminate the overhang of the roof. , high practicability, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

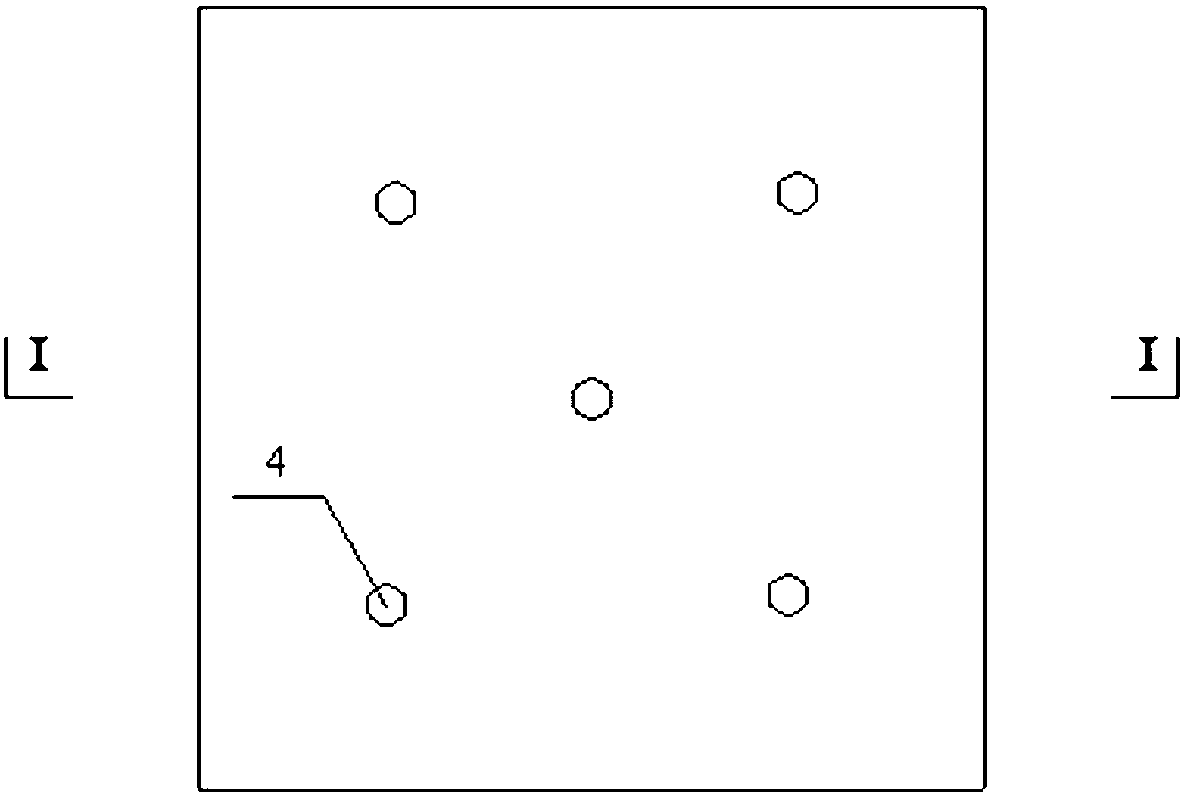

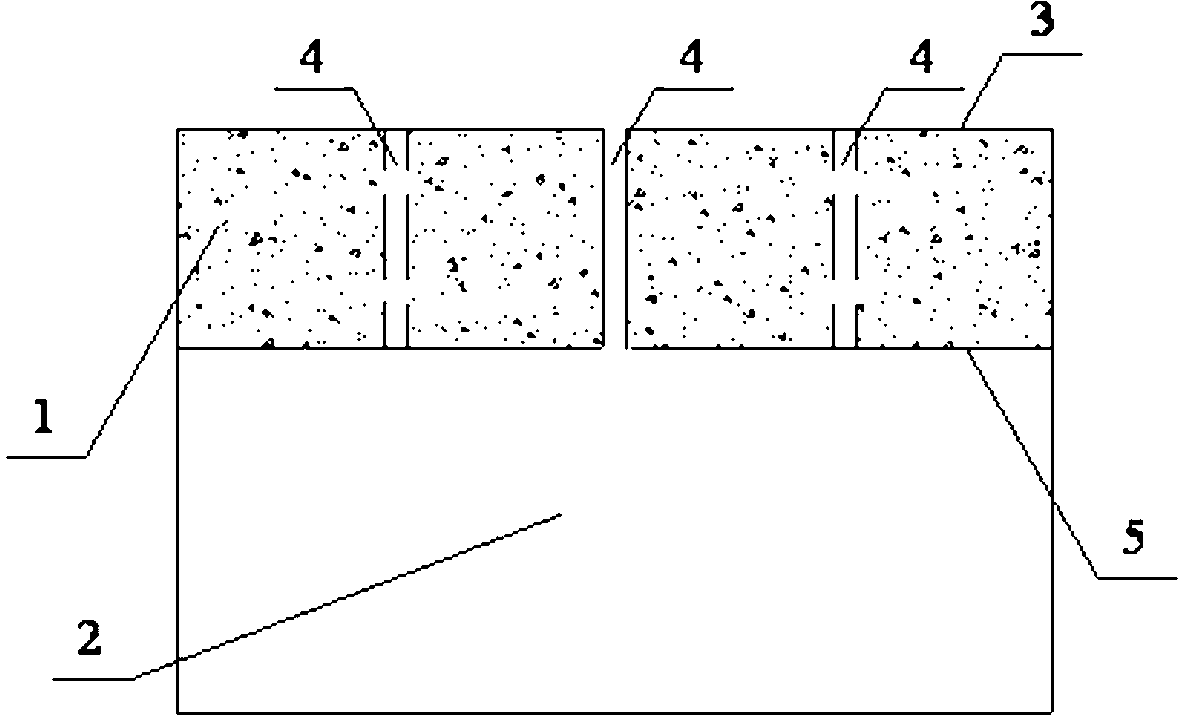

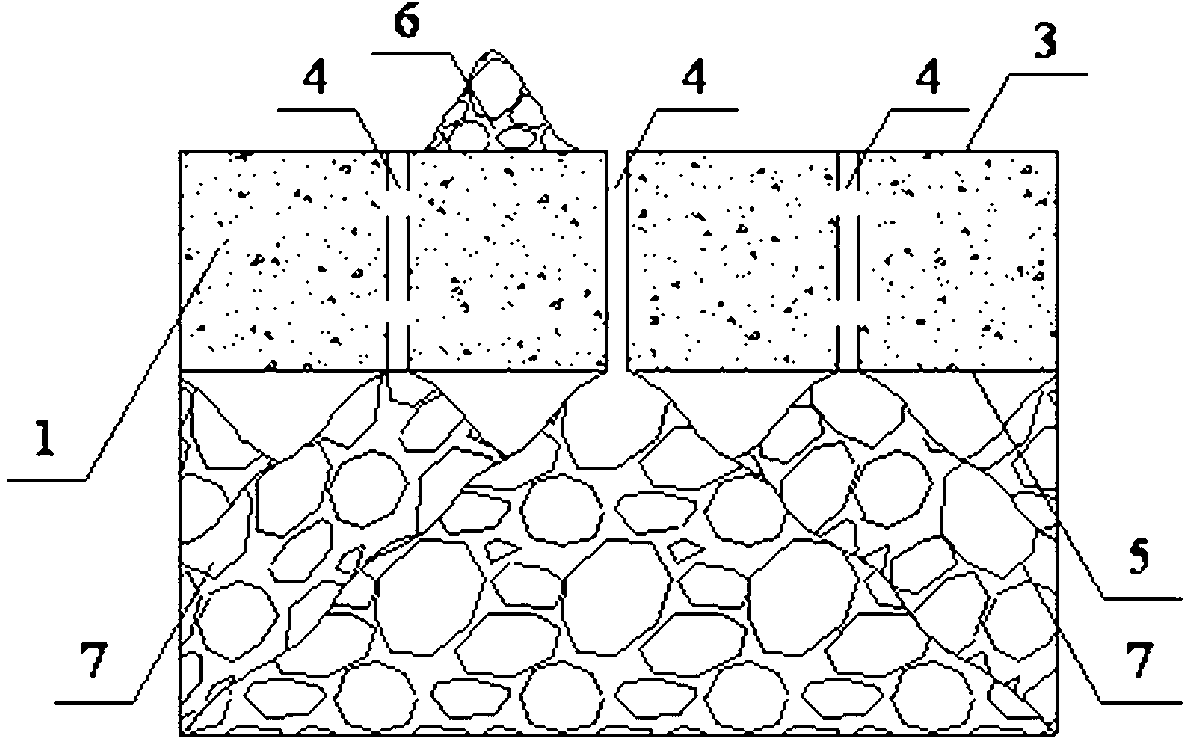

[0013] With reference to the accompanying drawings, the method of the present invention based on filling the sky and taking surface waste rocks to treat the goaf: when the thin bedrock 1 and the shallow buried goaf 2 are treated after mining, the full-section drilling method is adopted from the surface 3 by a drilling rig Drill down a plurality of raised wells 4 to goaf 2, and then take waste rock 6 on the surface to fill the goaf 2 by freely falling; The free fall of waste rock 6 on the surface; because the waste rock 7 freely falling through the same patio 4 cannot fill the goaf 2, in order to fill the goaf 2 as much as possible, at least three patios 4 must be drilled downward on the surface; At the same time, the surface waste rock 6 must be crushed so that it can be directly and freely dropped into the goaf 2 .

[0014] In this way, after the goaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com