Proton exchanging composite film and preparation method thereof

A proton exchange membrane and proton exchange technology, which can be applied to the components of fuel cells, etc., can solve the problems of reducing the permeability of methanol and destroying the mechanical properties of the proton exchange membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation method of a proton exchange composite membrane, comprising the following steps:

[0027] Mixing an amino group-containing organosilane with water to form a mixed solution;

[0028] adding an acid to the mixed solution to obtain a modified solution after reaction;

[0029] The proton exchange membrane is immersed in the modification solution, and the proton exchange composite membrane is obtained after reaction.

[0030] In the above preparation process, the present invention hydrolyzes the amino group-containing organosilane under acidic conditions, and uses the amino group-containing organosilane hydrolyzed under acidic conditions to modify the proton exchange membrane, so that the amino group-containing organic silane Silane and acid carry out sol-gel reaction on the surface of proton exchange membrane, and organosilane is modified on the surface of proton exchange membrane.

[0031] The structural formula of the organosilane co...

Embodiment 1

[0043] 1) Weigh 2.21 g of 3-aminopropyltriethoxysilane (APTES) and 18 g of water and stir at room temperature for 24 hours to form a mixed solution;

[0044] 2) Weighing 0.98g of concentrated sulfuric acid and gradually adding it into the mixed solution, keeping one drop per minute, stirring for 12 hours to form a modified solution;

[0045] 3) Take the Nafion117 membrane and heat it at 140° C. for 30 minutes, then immerse it in the modification solution for 5 seconds after cooling to obtain the modified proton exchange membrane, that is, the proton exchange composite membrane.

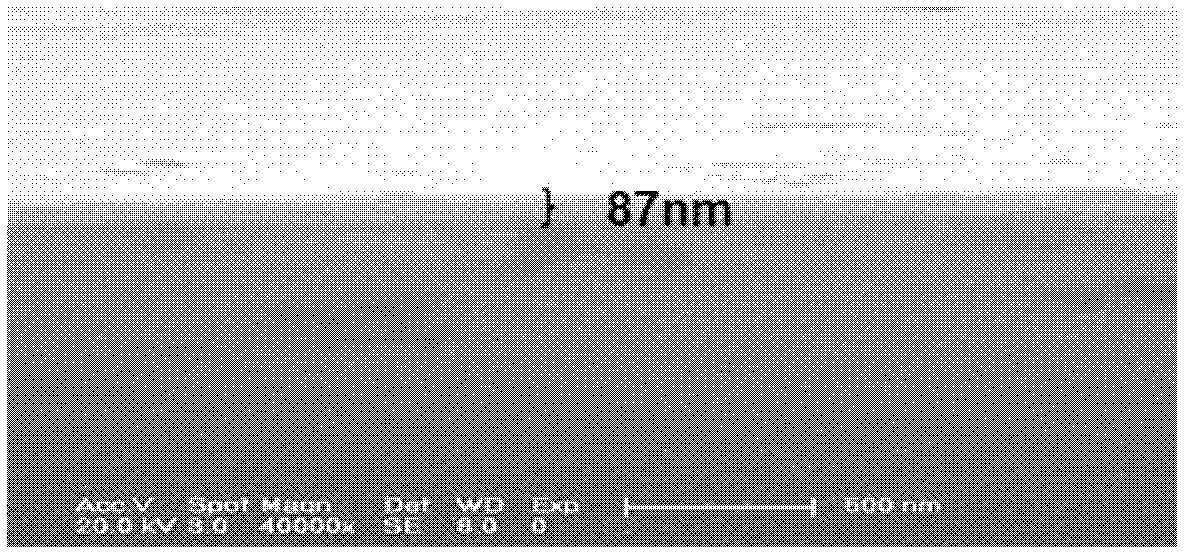

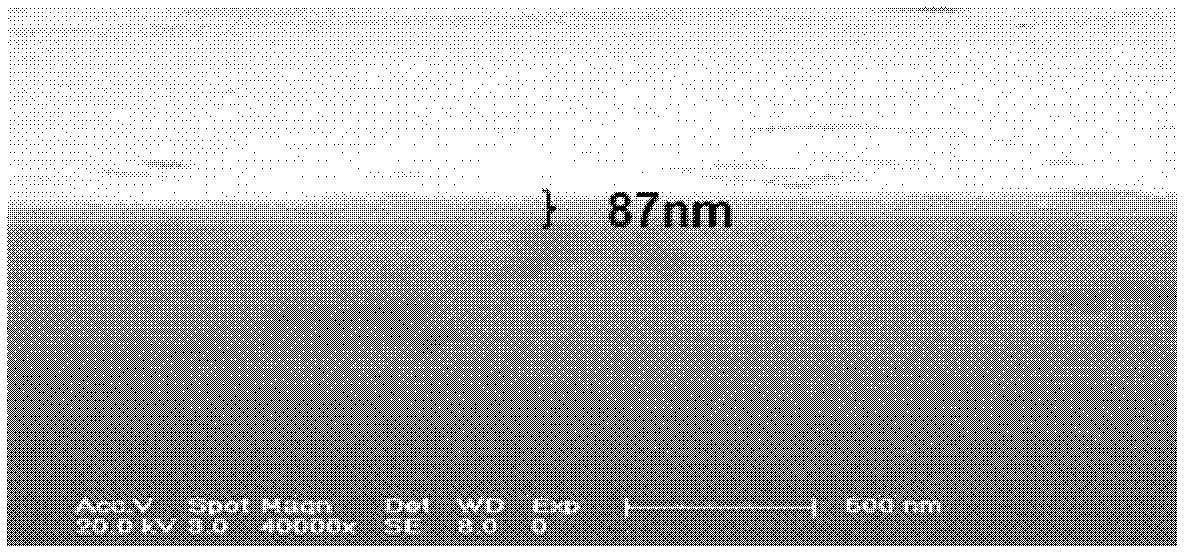

[0046] figure 1 Electron microscope pictures of the cross-section of the proton exchange composite membrane prepared for this example. In addition, the performance of the proton exchange composite membrane prepared in this example was measured, and the results showed that the proton conductivity of the proton exchange composite membrane prepared in this example was 0.09 Scm -1 , methanol permeabilit...

Embodiment 2

[0048] 1) Weigh 2.21 g of 3-aminopropyltriethoxysilane (APTES) and 18 g of water and stir at room temperature for 24 hours to form a mixed solution;

[0049] 2) Weigh 0.98g of concentrated sulfuric acid and gradually add it into the mixed solution, keeping it at one drop per minute, and stir for 12 hours to form a modified solution;

[0050] 3) Take the Nafion117 membrane and heat it at 140° C. for 30 minutes, then immerse it in the modification solution for 60 seconds after cooling to obtain the modified proton exchange membrane, that is, the proton exchange composite membrane.

[0051] figure 2 Electron microscope pictures of the cross-section of the proton exchange composite membrane prepared for this example. In addition, the performance of the proton exchange composite membrane prepared in this example was measured, and the results showed that the proton conductivity of the proton exchange composite membrane prepared in this example was 0.075 Scm -1 , methanol permeabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swelling factor | aaaaa | aaaaa |

| swelling factor | aaaaa | aaaaa |

| swelling factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com