Semi-fixed crushing station

A crushing station and semi-stationary technology, applied in the field of semi-stationary crushing station, can solve the problems of too large module, large vibration, inconvenient relocation, etc., and achieve the effect of reducing operating power consumption, improving service life and reasonable separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

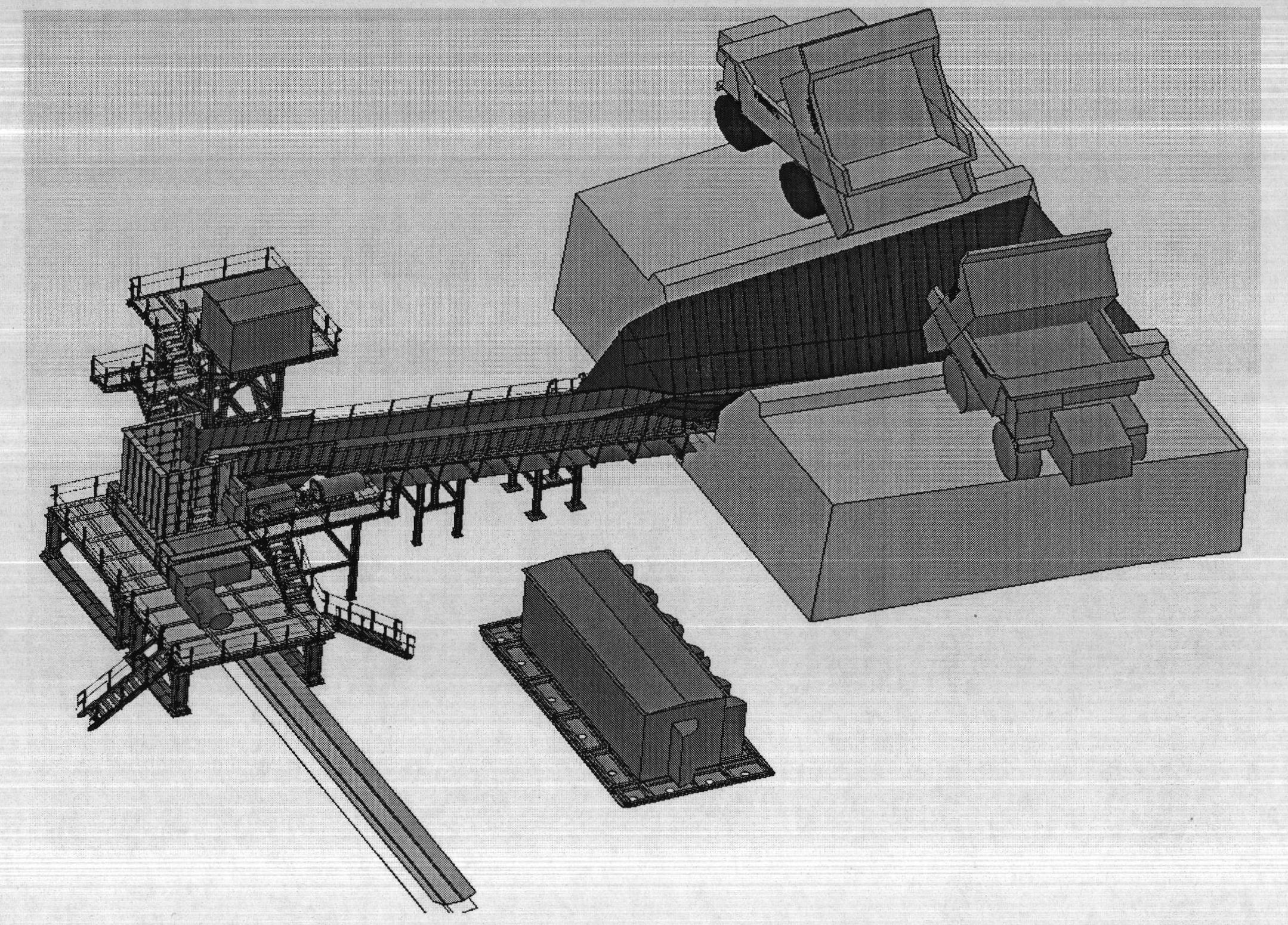

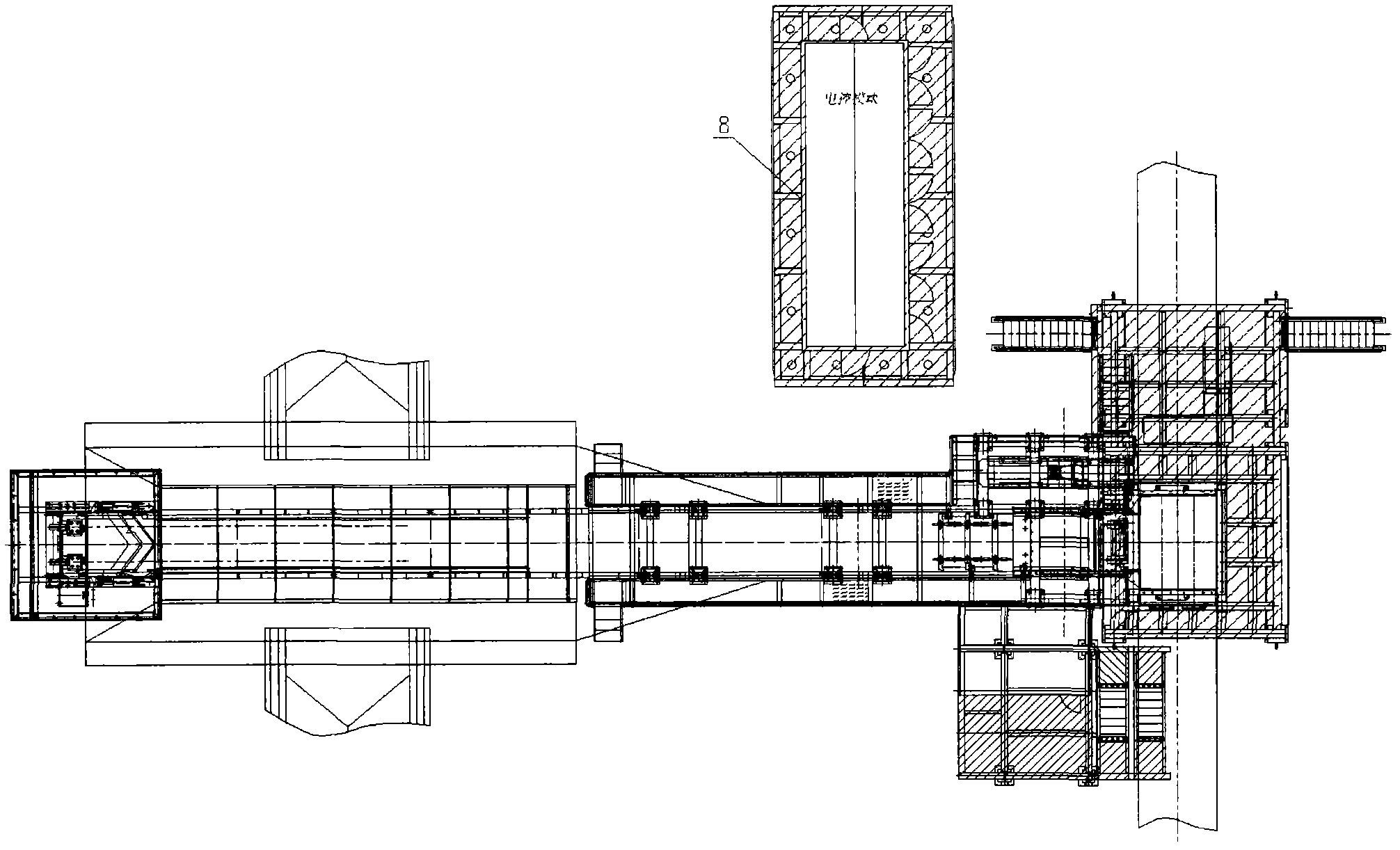

[0033] The invention relates to a semi-fixed crushing station for raw coal crushing and processing in an open-pit coal mine. Crusher support platform (3), operating room (4), phase change and power distribution room (8).

[0034] The scraper machine (1) is arranged obliquely at an angle of 5° to 11°. A coal flow height limiting device (5) is installed in the receiving section of the scraper machine (1). It is dragged by the scraper machine (1), sent to the machine head and unloaded into the double-toothed roller crusher (2), and then enters the discharge belt conveyor (7) under the crusher support platform (3) after crushing.

[0035] The scraper machine (1) is driven by frequency conversion, and the output frequency of the frequency converter is adjusted according to the height of the coal seam in the scraper machine (1) to change the operating speed of the scraper machine (1). Overload; on the other hand, according to the constant torque characteristic of the variable frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com