LED (Light-Emitting Diode) illuminating device and radiating structure thereof

A technology of LED lighting and heat dissipation structure, which is applied to lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Promote large-scale promotion and application, good heat dissipation effect and fast startup speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

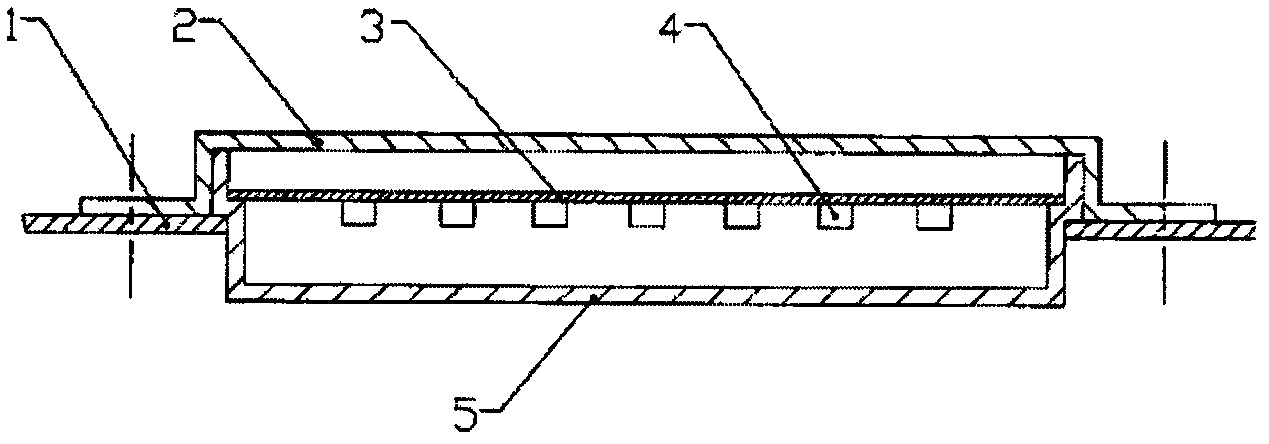

[0035] attached figure 1 It shows the structure diagram of the best embodiment of the LED lighting device of the present invention.

[0036] Attached below figure 1 Further describe the content and working principle of the present invention in detail.

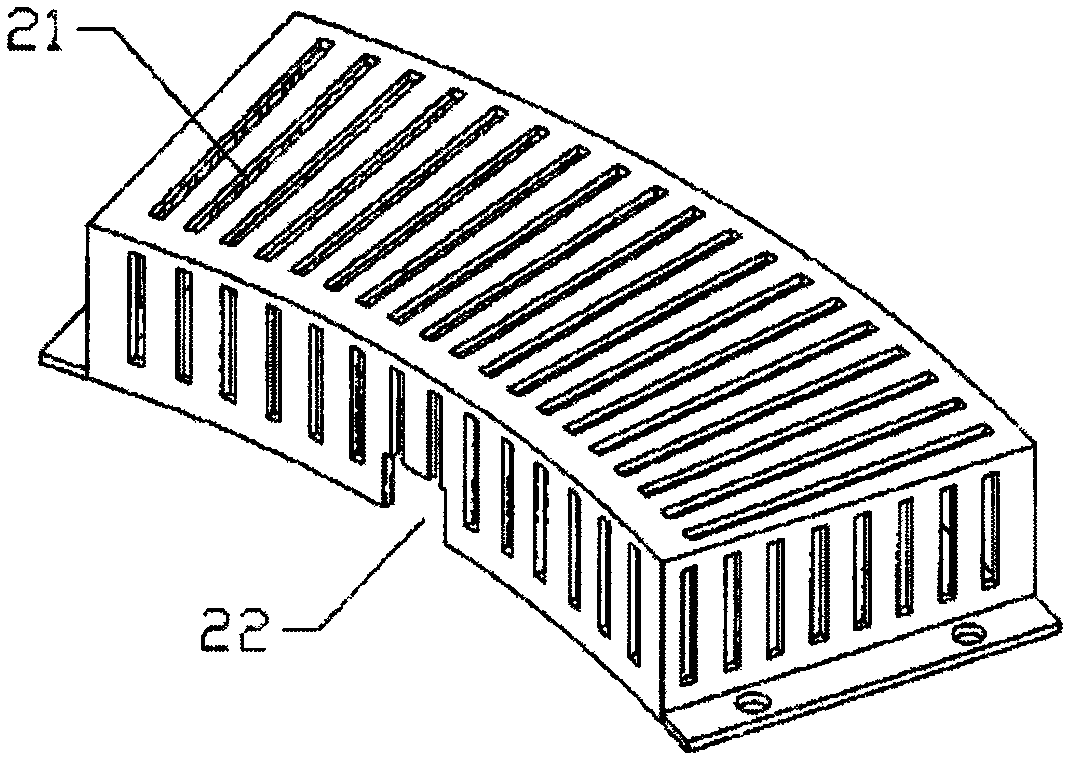

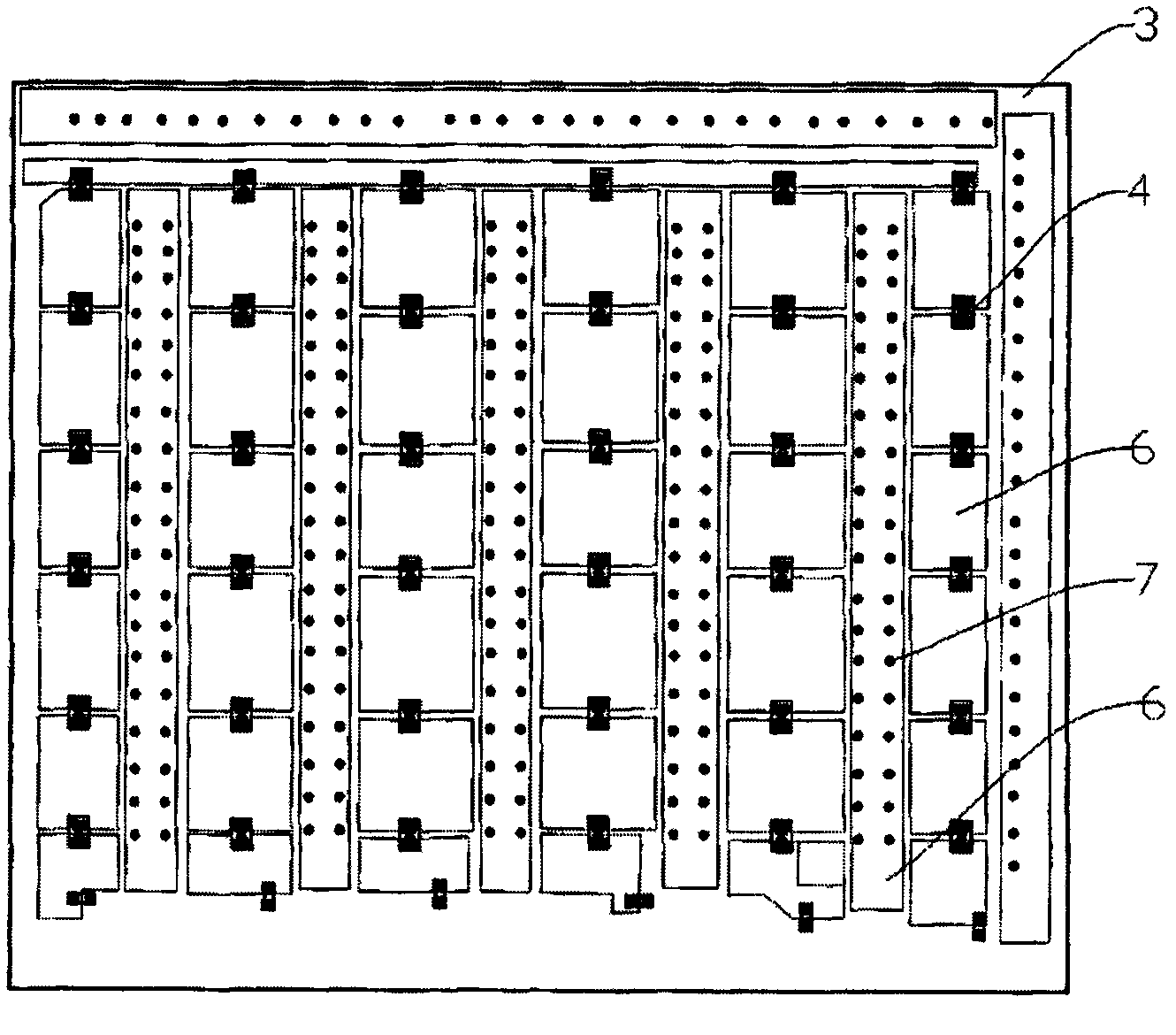

[0037] Marked in the figure: 1. Connection plate, 2. Protective cover plate, 3. Substrate, 4. LED particles, 5. Light-transmitting plate, 6. Copper clad (or aluminum clad), 7. Small through hole, 21. Heat dissipation Hole, 22, through hole or groove.

[0038] When the LED lighting device of the present invention is applied to a high-power LED, when the PCB board is used as the substrate, since the heat generated by the high-power LED is relatively large, the conduction of the LED is welded on the top surface of the substrate 3 or the printed circuit board. Block copper (or aluminum) 6, large copper (or aluminum) 6 instead of the original wire, has the dual effects of conduction and heat dissipation, the area of the large c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com