Ultramicro powder epimedium constant-temperature preparation method and dedicated bidirectional air flow screening machine thereof

A technology of epimedium and ultrafine powder, applied in the field of veterinary drug additives, can solve the problems of restricting the large-scale production of veterinary traditional Chinese medicine ultrafine powder, low bioavailability, poor fluidity, etc. The rate of cell wall breaking and the effect of enhancing pharmacological action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

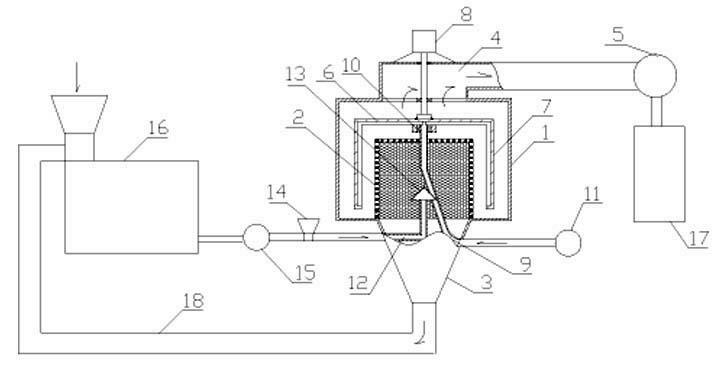

[0027] Such as figure 1 , 2 Shown, the normal temperature preparation method of superfine powder Epimedium of the present invention comprises the following steps:

[0028] The first step is to select high-quality Epimedium with few stems, many leaves, yellow-green color, and not broken. Among them, the quality of Epimedium lobularis produced in Northwest China is the best, and the content of Epimedium rickets is not less than 1.0%. Air-dried or oven-dried to a moisture content of ≤10%;

[0029] In the second step, the Epimedium is pulverized at 20°C to 25°C to obtain a coarse powder with a particle size of 60-80 mesh;

[0030] The third step, at first turn on the powder conveying fan 15, the induced draft fan 5, the blower 11, and the drive motor 8. The blowing pressure of the powder conveying fan 15 is 24kpa, and the blowing volume is 150m 3 / h; the induced air pressure of the induced draft fan 5 is 1000pa, and the induced air volume is 3000m 3 / h; the blast pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com