Extended electrode for photovoltaic tellurium-cadmium-mercury probe and preparation method for extended electrode

A technology for extending electrodes and mercury cadmium telluride, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of small forbidden band width of long-wave detectors, reduced device performance, and easy formation of leakage currents, so as to ensure electrical connectivity, Improve the effect of edge shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

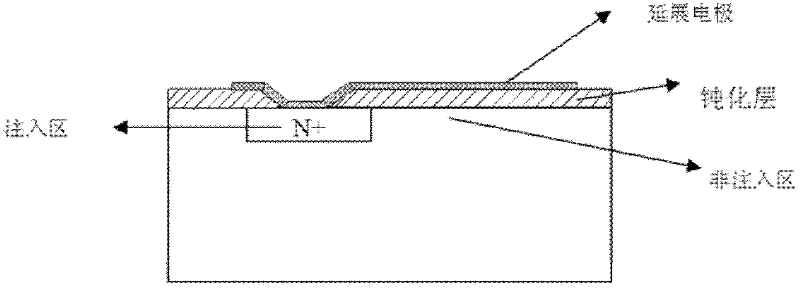

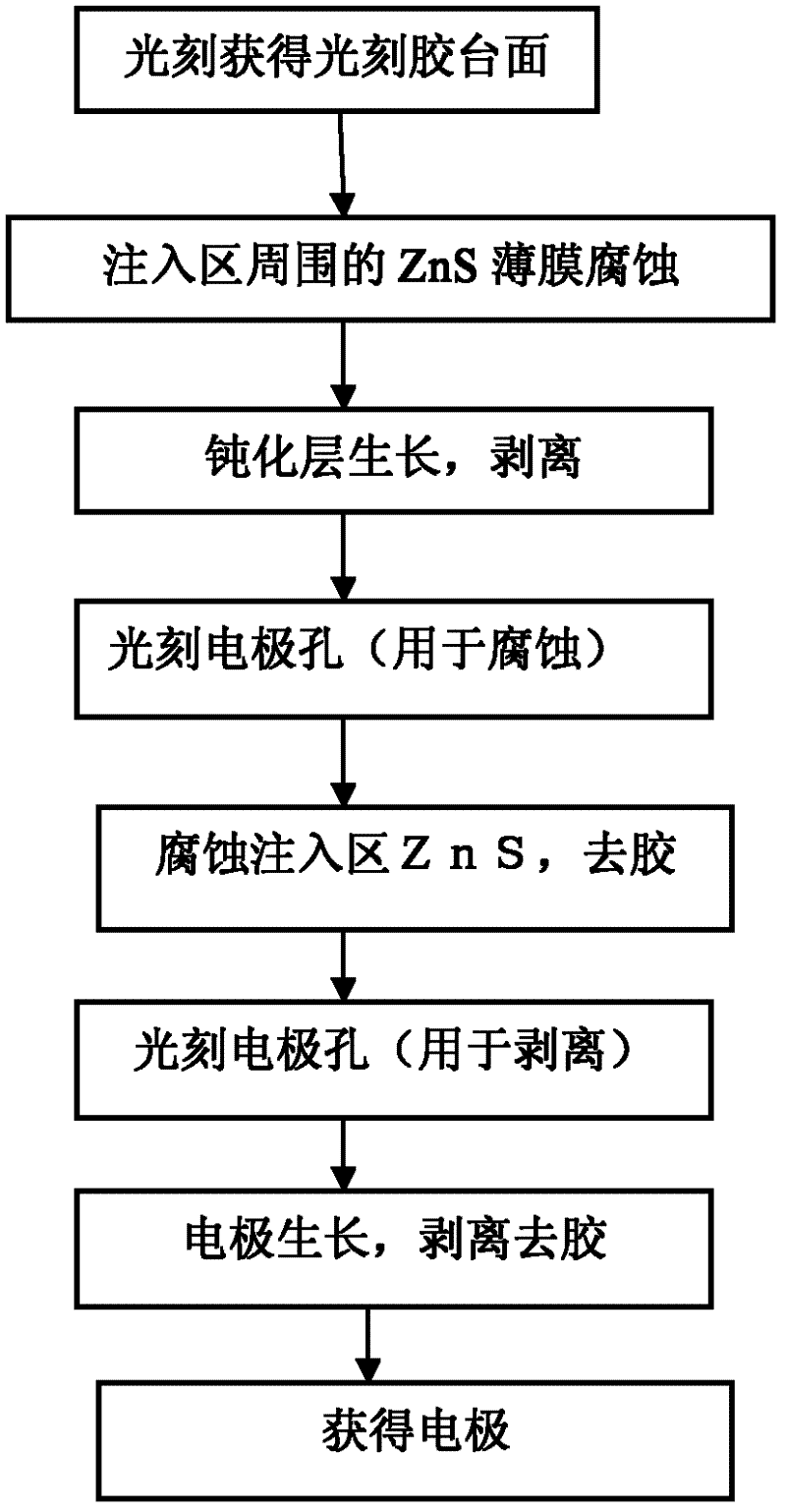

[0022] Below in conjunction with the accompanying drawings, the embodiment of the present invention will be described in detail by taking a chip with a center-to-center distance of 28 microns and an indium column array of 256x1 as an example:

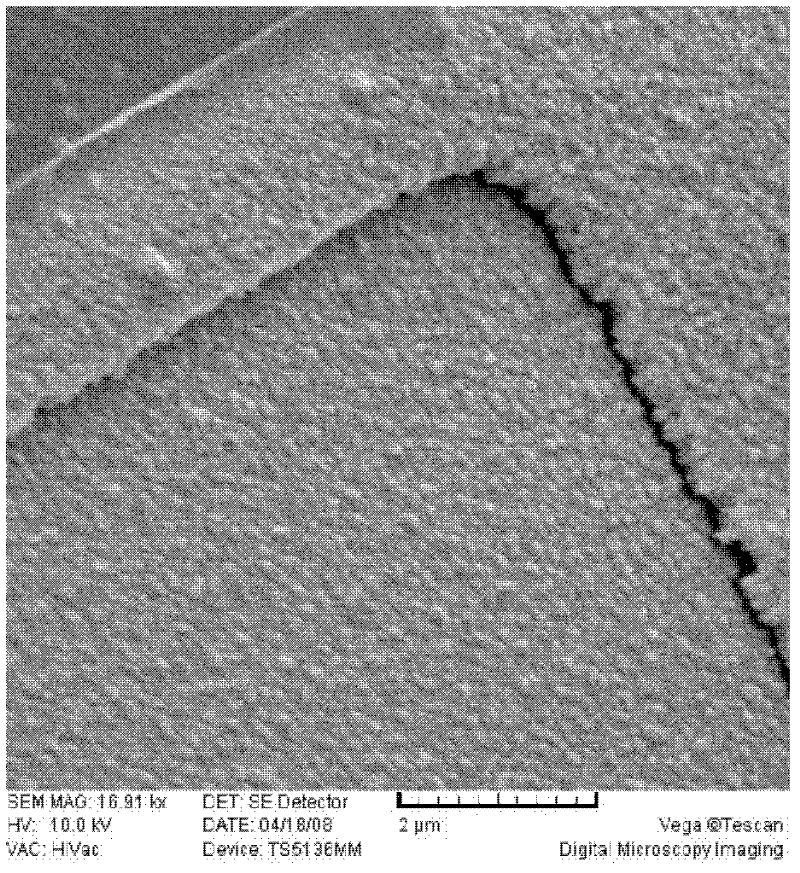

[0023] The embodiment of the present invention adopts the mercury cadmium telluride infrared chip on which the ZnS protective layer has been grown to grow the extended electrode. The preparation method of the extended electrode described in the present invention refers to using a negative photoresist to expose photolithography on the mercury cadmium telluride infrared chip that needs to be prepared to obtain a photoresist mesa with a large top and a small bottom. The pattern shadow effect of the photoresist mesa, grow a compound passivation layer with gradually changing thickness around the pn junction implantation area on the surface of the mercury cadmium telluride chip, grow a layer of electrodes on the pn junction implantation area a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com