Low-temperature-resistant bending-resistant cable for charging new energy automobile

A new energy vehicle, low temperature resistance technology, applied in the direction of bendable cables, insulated cables, bendable conductors, etc., can solve problems such as cable cracks, softness, safety hazards, etc., to prevent water leakage, reduce Resistive flow and the effect of reducing resistance leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

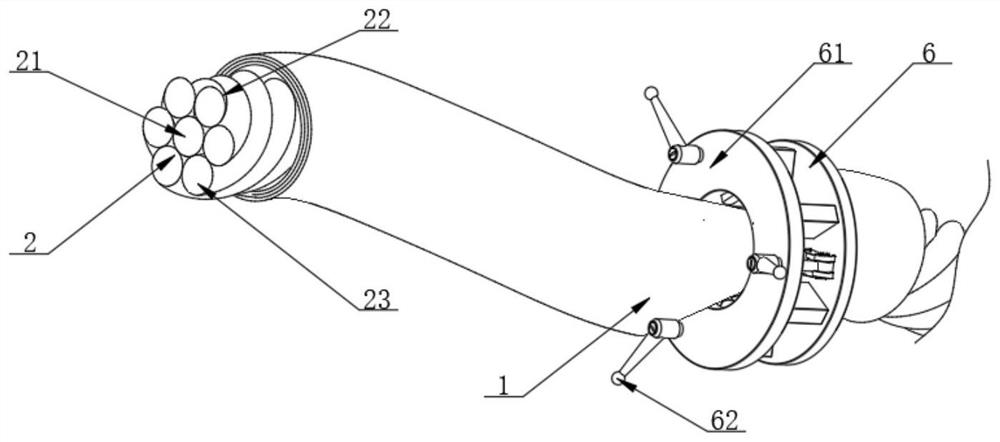

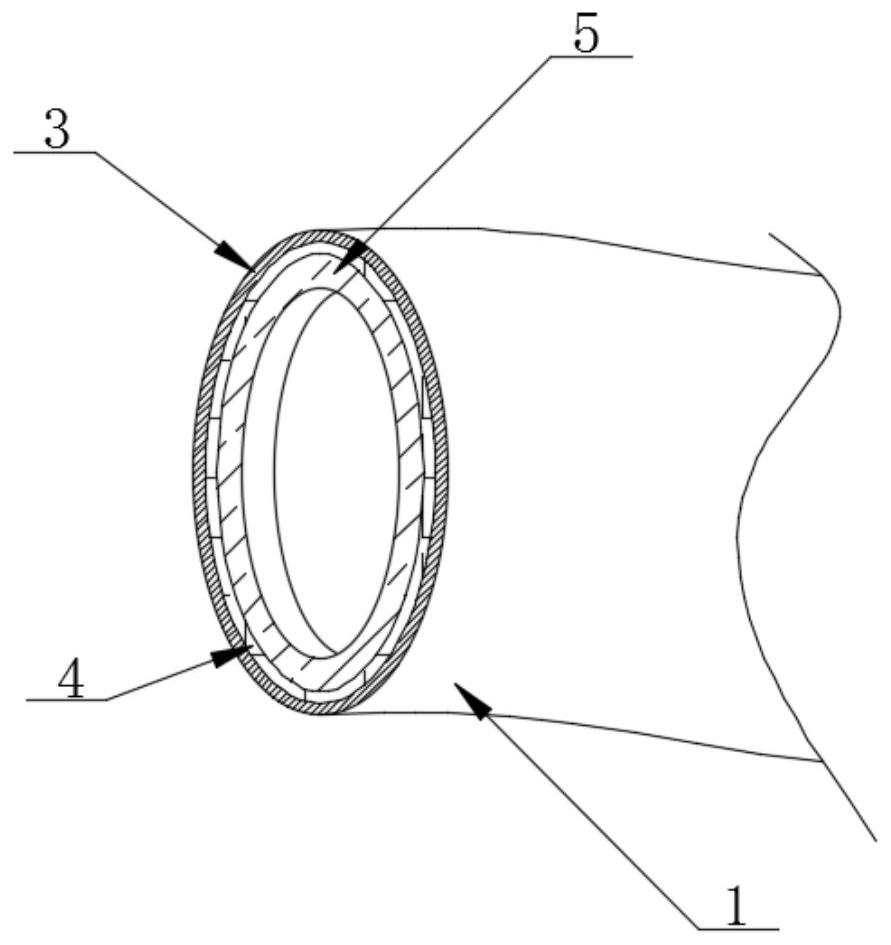

[0027] refer to Figure 1-4 As shown, a low-temperature and bending-resistant cable for charging new energy vehicles includes a cable body 1 and a central conductive layer 2. The cable body 1 is sequentially provided with a temperature-resistant layer 3, a bending-resistant layer 4, and a shielding layer 5 from the inside to the outside. .

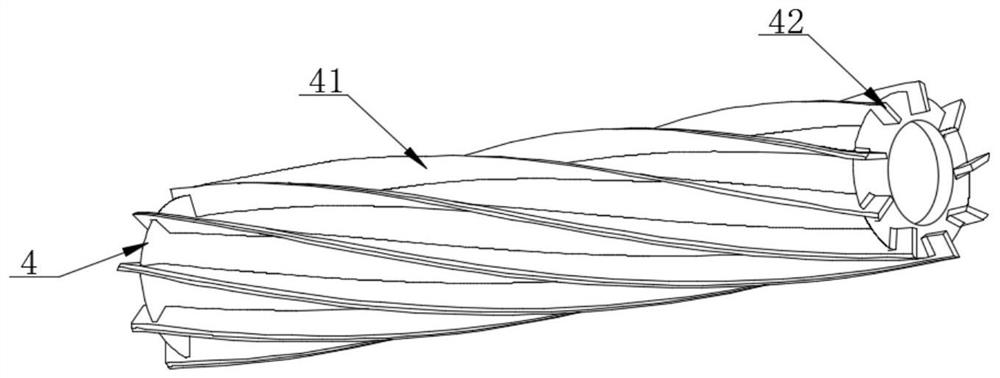

[0028] In this embodiment, a cavity is provided between the temperature-resistant layer 3 and the bending-resistant layer 4, and the bending-resistant layer 4 has a cylindrical structure through the center, and several wedge-shaped protrusions 41 are fixed on the surface of the bending-resistant layer 4, and the temperature-resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com