Electrode substrate and manufacturing method thereof

A technology for electrode substrates and manufacturing methods, which is applied in the direction of electrical digital data processing, conductive layers on insulating carriers, instruments, etc., can solve problems such as unusable substrates, many man-hours, and increased manufacturing costs of electrode substrates, and achieve reduction in heating processes, Reduced man-hours and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

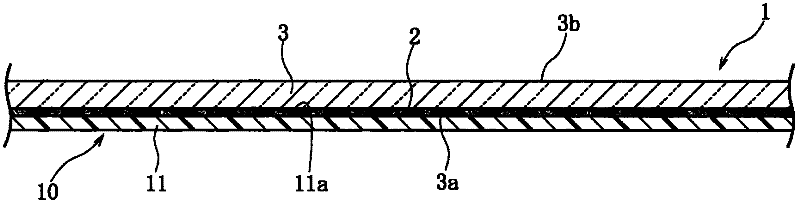

[0069] figure 1 The shown capacitive detection device 1 includes an electrode substrate 10 according to an embodiment of the present invention. The electrode substrate 10 has a substrate 11 formed of a light-transmitting synthetic resin film such as PET (polyethylene terephthalate). 3a engagement. The adhesive layer 2 is formed of a light-transmitting adhesive such as acrylic. The operation panel 3 is formed of a translucent synthetic resin plate such as polycarbonate, a translucent glass plate, or the like.

[0070] In this specification, light transmittance means that the overall light transmittance is 60% or more, preferably 80% or more.

[0071] figure 1 The detection device 1 shown is arranged in front of a self-luminous display device such as a liquid crystal display device equipped with a backlight, and the display content of the display device can be visually observed through the detection device 1 .

[0072] The front surface of the operation panel 3 of the detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width size | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com