Multicomponent alloy composite anticorrosive coating for metal pipe/pipe fitting

A multi-element alloy and anti-corrosion coating technology, which is applied in the coating process of metal materials, pipeline anti-corrosion/rust protection, pipes/pipe joints/fittings, etc., can solve the problem of increased suspended particles, coating foaming, dizziness, nausea, Fever and other problems, achieve the effect of low porosity and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Pipe surface treatment

[0054] Surface treatment of cast iron pipes and pipe fittings before thermal spraying to remove impurities such as oil, water, and dust.

[0055] (2) Arc spraying alloy coating

[0056] Arc thermal spraying equipment composed of high-power spraying power supply, spraying gun, wire feeding mechanism, air compressor, and control box is selected, and the weight of φ2.0mm is composed of Zn 56%; Al 41%; Mg 2.0%; RE 1.0% The multi-element alloy wire is used as the metal wire for arc thermal spraying, according to 130g / m 2 Spray on the surface of the pipeline to form a multi-element alloy composite anti-corrosion coating.

[0057] (3) Coating the sealing finish coating

[0058] Coating epoxy resin on the surface of the multi-component alloy layer to seal the alloy layer, the thickness of the final sealing layer is 110 μm.

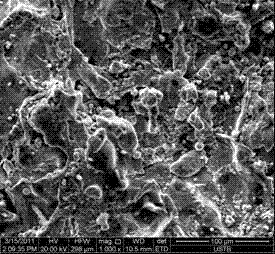

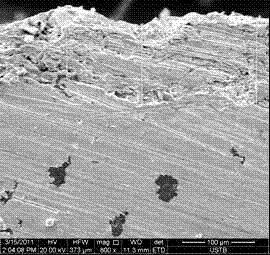

[0059] figure 1 , figure 2 It is the SEM morphology analysis diagram of the surface structure and cross-section struct...

Embodiment 2

[0061] (1) Pipe surface treatment

[0062] Surface treatment of cast iron pipes and pipe fittings before thermal spraying to remove impurities such as oil, water, and dust.

[0063] (2) Arc spraying alloy coating

[0064] The electric arc thermal spraying equipment composed of high-power spraying power supply, spraying gun, wire feeding mechanism, air compressor and control box is selected, and the weight of φ4.0mm is composed of Zn 78%; Al 20%; Mg 1.5%; RE 0.5% The multi-element alloy wire is used as the metal wire for arc thermal spraying, according to 200g / m 2 Spray on the surface of the pipeline to form a multi-element alloy composite anti-corrosion coating.

[0065] (3) Coating the sealing finish coating

[0066] On the surface of the multi-component alloy layer, high-pressure airless spraying asphalt is used to seal the alloy layer, and the thickness of the sealing final layer is 100 μm.

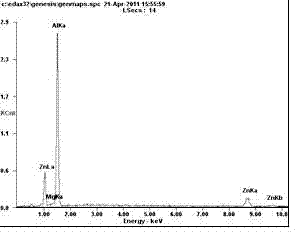

[0067] image 3 It is the EDS analysis diagram of multi-element alloy composi...

Embodiment 3

[0069] (1) Pipe surface treatment

[0070] Surface treatment of cast iron pipes and pipe fittings before thermal spraying to remove impurities such as oil, water, and dust.

[0071] (2) Arc spraying alloy coating

[0072] Arc thermal spraying equipment composed of high-power spraying power supply, spraying gun, wire feeding mechanism, air compressor, and control box is selected, and the weight of φ3.0mm is composed of Zn 70%; Al 29.2%; Mg 0.75%; RE 0.05% The multi-component alloy wire is used as the metal wire for arc thermal spraying, according to 250g / m 2 Spray on the surface of the pipeline to form a multi-element alloy composite anti-corrosion coating.

[0073] (3) Coating the sealing finish coating

[0074] The surface of the multi-element alloy layer is coated with acrylic resin to seal the alloy layer, and the thickness of the final sealing layer is 130 μm.

[0075] Figure 4 It is a comparison chart of the electrochemical AC impedance spectrum of the multi-element...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com