Construction method for concrete-filled steel tube arched bridge with large low-buckle tower erection bridge width

A technology of steel pipe concrete and construction methods, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of small horizontal inclination angle of buckle cables, influence of structural force, etc., reduce maximum tensile stress, reduce height and cost, The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

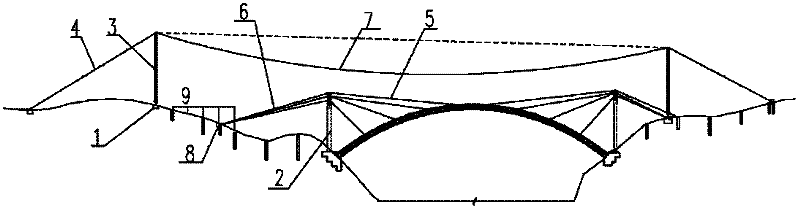

[0023] An overhanging concrete-filled steel tube catenary hingeless arch bridge in a mountainous area, the design arch axis coefficient is 1.65, the calculated span is 255m, the rise-span ratio is 1 / 5.5, and the calculated rise height is 46.364m; The span is 255m, and the calculated vector height is 46.864m. The main arch ring is composed of two arch ribs, and each arch rib structure is designed as a four-tube truss member of equal cross-section steel tube concrete, with a truss height of 5m and a width of 4.6m. The upper chord of the truss structure is two φ1100mm steel pipes, and the wall thickness is divided into three sections: 24mm, 20mm, and 24mm from the vault to the arch foot; the lower chord is two φ1100mm steel pipes, and the wall thickness is divided into 20mm, 20mm, and There are three sections of 24mm and 28mm; vertical webs and oblique webs are set between the upper and lower chords, and double vertical webs are installed at the column position. The bridge is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com