Anti-counterfeit paper added with anti-counterfeit short fiber and manufacturing method thereof

A manufacturing method and a technology of short fibers, which are applied to anti-counterfeiting paper added with anti-counterfeiting short fibers and its manufacturing field, can solve problems such as improper use of anti-counterfeiting short fibers, hair loss, and printing difficulties, and achieve rich anti-counterfeiting performance and enhanced edge tearing The effect of improving strength and flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

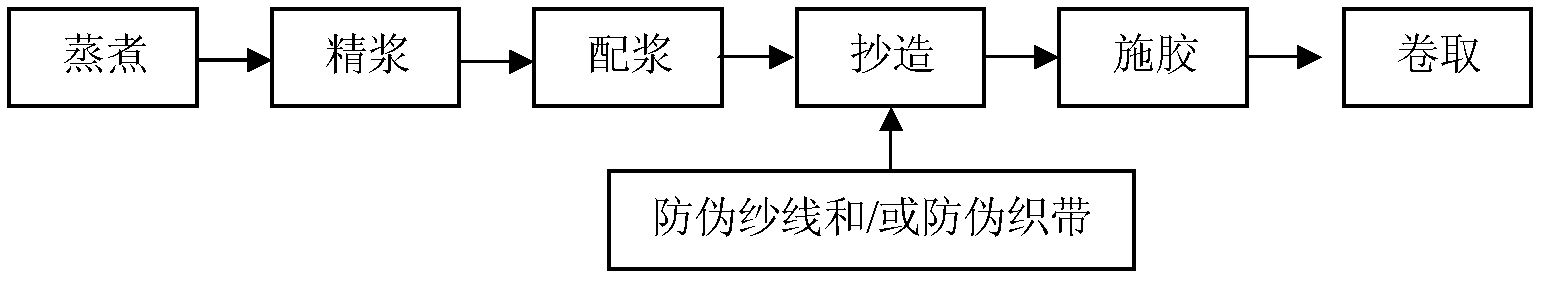

[0057]The preparation of anti-counterfeiting paper mainly includes the following steps: fine pulping step, pulping step, papermaking step, sizing step, drying step, such as figure 2 As shown, specifically:

[0058] Refining step: beating fiber raw materials (such as cotton pulp, wood pulp, straw pulp, hemp pulp, etc.) in a refiner to obtain pulp;

[0059] Pulp mixing step: add chemical additives, fillers, other additives, etc. to the refined pulp, and stir evenly; the chemical additives generally use reinforcing agents such as urea-formaldehyde resin and melamine-formaldehyde resin, and the fillers can be selected from Titanium dioxide, kaolin, talcum powder, etc. Other additives can be selected from one or more of retention aids, filter aids, defoamers, etc.; the specific ratio can be carried out according to the conventional operation of the prior art;

[0060] Papermaking step: Use a paper machine to make paper pulp after pulp preparation to obtain anti-counterfeit cloth ...

Embodiment 1

[0088] This embodiment provides a kind of anti-counterfeiting paper, which is mainly prepared according to the following steps:

[0089] 1. Preparation of anti-counterfeiting long fibers: immerse the adhesive filament (white) spindle in a carbon tetrachloride solution dissolved with quantum dot materials, the concentration of quantum dot materials in the solution is 1-200ppm (preferably 2-100ppm), Preparation of adhesive filaments loaded with quantum dots, the quantum dot material will emit red light when excited by ultraviolet light with a wavelength of 640nm;

[0090] 2. Cut the above-mentioned anti-counterfeit long fibers into anti-counterfeit staple fibers of 38mm, mix 2-30% of water-soluble vinylon staple fibers with a hot-melt temperature of 65°C, 69.999%-87.999% of cotton fibers with the above-mentioned anti-counterfeit staple fibers of 0.001% proportion, According to the traditional spinning process, 100 anti-counterfeiting yarns with quantum dot anti-counterfeiting ch...

Embodiment 2

[0102] This embodiment provides a kind of anti-counterfeiting paper, which is mainly prepared according to the following steps:

[0103] 1, the preparation of anti-counterfeit long fiber is the same as embodiment 1;

[0104] 2. Cut the above-mentioned anti-counterfeiting long fibers into 50mm anti-counterfeiting short fibers, mix 20% of water-soluble vinylon staple fibers with a hot melting temperature of 65°C, 79.998% of cotton fibers with the above-mentioned anti-counterfeiting short fibers of 0.002% proportion, according to the traditional spinning process 100 anti-counterfeiting yarns with quantum dot anti-counterfeiting features are made through carding, sliver, spinning and other processes;

[0105] 3. Make the above-mentioned anti-counterfeiting yarns as weft and warp, and use a narrow-width loom to obtain a webbing through a weaving process, that is, the anti-counterfeiting webbing of this embodiment. The width of the webbing is 10mm, and the side weft of the webbing i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com