Anti-counterfeiting seat belt and anti-counterfeiting paper applied to the anti-counterfeiting seat belt

A technology for seat belts and anti-counterfeiting paper, which is applied in papermaking, textiles and papermaking, and non-fiber pulp addition, etc., can solve the problems of inability to perform instrument detection, uneven paper surface, poor thread-paper bonding fastness, etc., and achieve good anti-counterfeiting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] This embodiment provides a kind of anti-counterfeiting paper, which mainly includes the following steps:

[0102] 1. Prepare anti-counterfeiting long fibers: immerse the adhesive filament (white) spindle in a carbon tetrachloride solution that is dissolved with quantum dot materials, and the concentration of quantum dot materials in the solution is 1-200ppm (preferably 2-100ppm), Prepared adhesive filaments loaded with quantum dots, which emit green light when excited by ultraviolet light with a wavelength of 417nm;

[0103] 2. Warp the above-mentioned anti-counterfeit long fibers and the adhesive long fibers without quantum dot material treatment through a warping machine;

[0104] 3. Wefting hot-melt fiber filaments with a hot-melt temperature of 80°C;

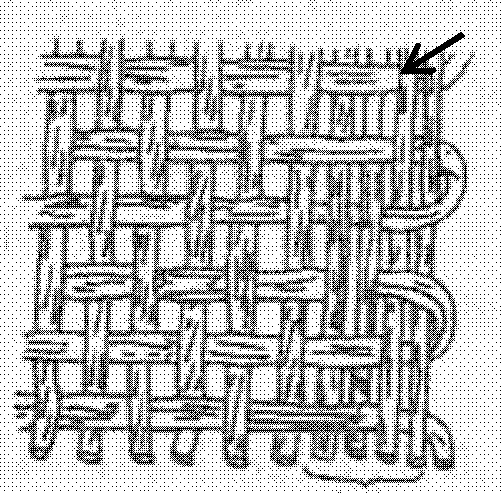

[0105] 4. Use a narrow-width loom to obtain a webbing (i.e., an anti-counterfeit safety belt) through a weaving process. The width of the webbing is 10 mm. The side warp of the webbing is an adhesive filament with qu...

Embodiment 2

[0110] This embodiment provides a kind of anti-counterfeiting paper, which mainly includes the following steps:

[0111] 1. Use polyester filaments to warp, weft and weave to obtain ribbons. The width of the ribbon is 4mm. The weaving density of the ribbon is: warp density 60 / cm, weft density 60 / cm;

[0112] 2. Mix red fluorescent powder into the red ink, the particle size of the fluorescent powder is 100 μm, and the added amount accounts for 10% of the weight of the red ink to obtain a red fluorescent ink, which appears red under 365nm ultraviolet excitation light;

[0113] Mix the blue heat-sensitive material into the white ink, the particle size of the blue heat-sensitive material powder is 80 μm, and the added amount accounts for 5% of the weight of the white ink to obtain the blue temperature-changing ink;

[0114] 3. The above two kinds of inks are printed on the webbing as stems and branches of snowflakes by screen printing to obtain anti-counterfeit safety belts;

[0...

Embodiment 3

[0120] Example 3 anti-counterfeiting paper

[0121] The present embodiment provides a kind of anti-counterfeit paper, and it is applied with the webbing (anti-counterfeit safety belt) that embodiment 1 prepares, and it obtains through the following steps:

[0122] According to the conventional papermaking process, two cylinders are used for papermaking. During the papermaking process, the webbing is compounded into the wet paper sheet, and then through the subsequent papermaking steps, the anti-counterfeiting paper with the anti-counterfeiting safety belt is prepared;

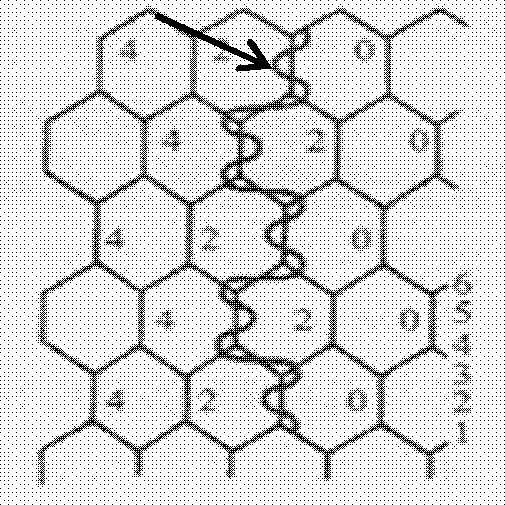

[0123] Among them, the release of the webbing is as follows: Figure 7 Shown:

[0124] First, the cylinder wire 3 forms a wet paper sheet 5 and is transferred to the fourdrinier wire 4 by contacting with the fourdrinier wire 4;

[0125] Then, the ribbon 1 enters the slurry liquid 9 driven by another cylinder 3 (cage 2), and then contacts the cylinder 3, and forms another layer of wet paper with an anti-counte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com