Acid-washing corrosion-inhibition fog inhibitor

A fog suppressing agent and corrosion inhibiting technology, applied in the field of fog suppressing agents, can solve the problems of unstable foam layer formation, unsuitable for industrial production, large amount of addition, etc., to alleviate acid mist odor, good corrosion inhibition effect, and foam formation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of fog suppressant, the steps are as follows:

[0036] 1. First dissolve the solid material and water;

[0037] Solid material: hexamethylenetetramine, sodium gluconate, oxalic acid, sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium benzoate

[0038] 2. Then add the liquid material and stir;

[0039] Liquid material: fatty alcohol polyoxyethylene ether sulfate, octadecethoxyethylene ether, alkylphenol polyoxyethylene ether, penetrating agent

[0040] 3. Add additives and mix thoroughly;

[0041] Additives include: coconut oil fatty acid diethanolamide, foam stabilizer, essence, fatty alcohol polyoxyethylene ether, leveling agent

[0042] 4. After mixing evenly, let it stand for 4-8 hours;

[0043] 5. Discharge.

Embodiment 1

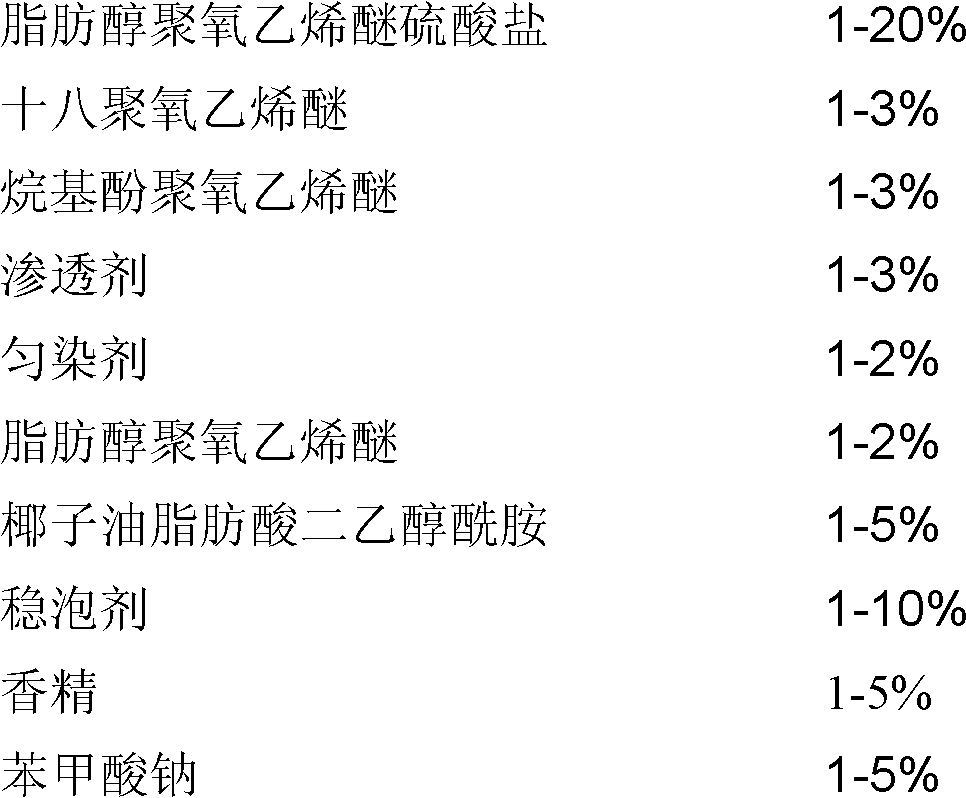

[0045] A pickling anti-corrosion anti-fog agent, comprising the following components and weight percentages:

[0046]

[0047]

[0048] The preparation method of fog suppressant, the steps are as follows:

[0049] 1. First dissolve the solid material and water;

[0050] Solid material: hexamethylenetetramine, sodium gluconate, oxalic acid, sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium benzoate;

[0051] 2. Then add the liquid material and stir;

[0052] Liquid material: fatty alcohol polyoxyethylene ether sulfate, octadecyl polyoxyethylene ether, alkylphenol polyoxyethylene ether, penetrating agent;

[0053] 3. Add additives and mix thoroughly;

[0054] Additives include: coconut oil fatty acid diethanolamide, foam stabilizer, essence, fatty alcohol polyoxyethylene ether, leveling agent;

[0055] 4. After mixing evenly, let it stand for 4-8 hours;

[0056] 5. Discharge.

Embodiment 2

[0058] A pickling anti-corrosion anti-fog agent, comprising the following components and weight percentages:

[0059]

[0060]

[0061] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com