Direct-current (DC) 1500V four-rail mounting structure applied to urban rail transit

A technology for urban rail transit and installation structure, applied in power rails, overhead lines, etc., can solve the problems of increased stray current leakage, potential difference, affecting the reliability of the power supply system, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

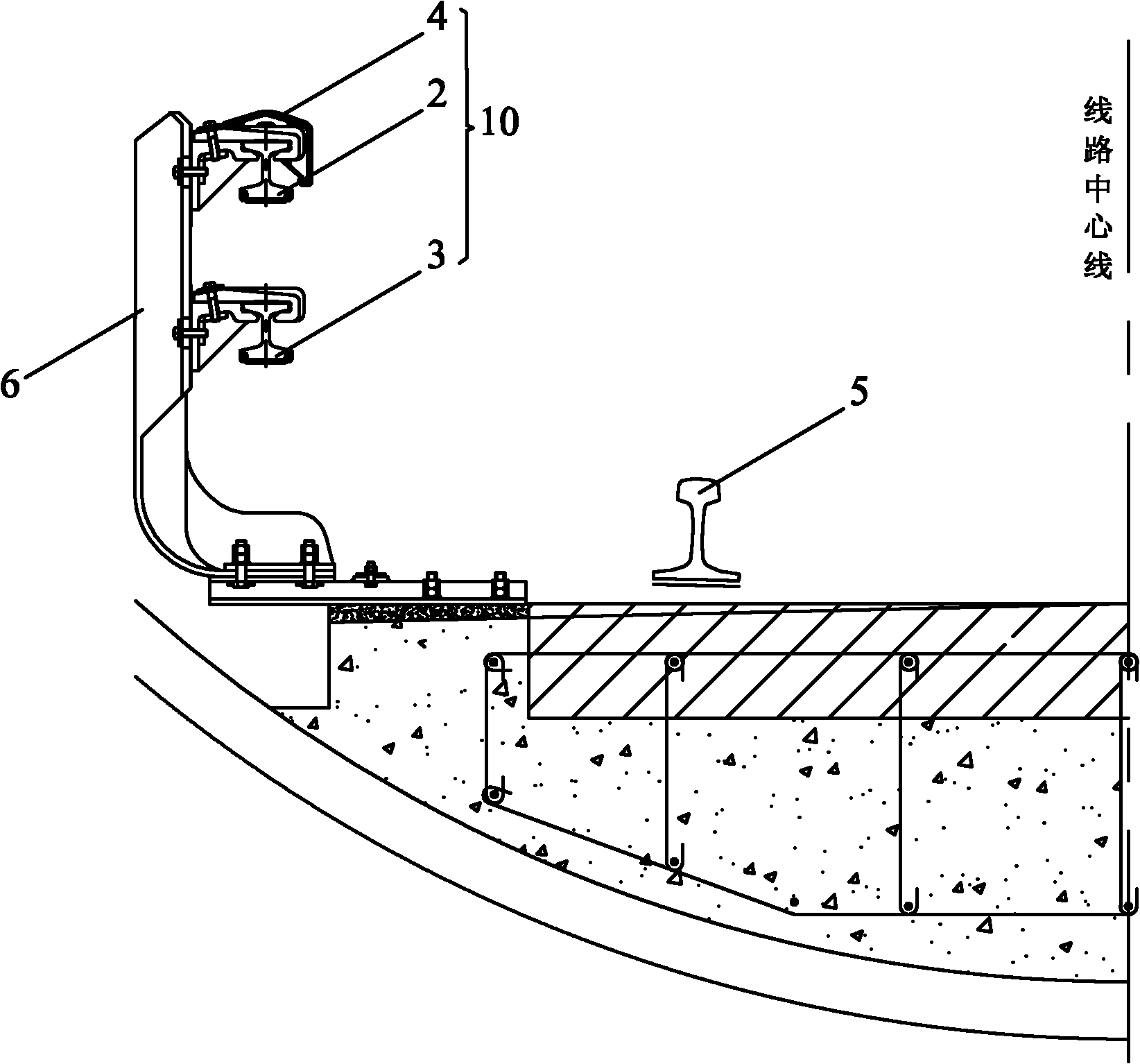

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] 1. Generation of stray current in urban rail transit and traditional protection methods:

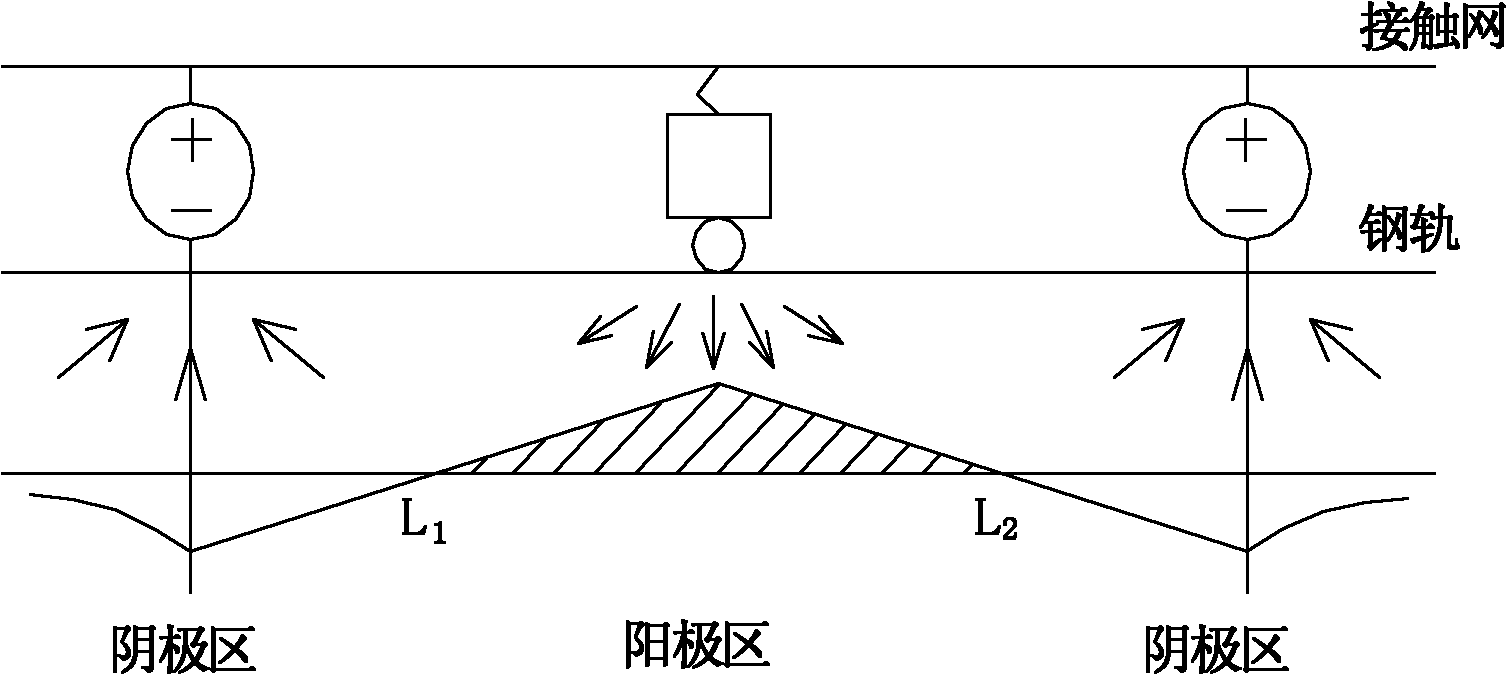

[0021] 1. Generation of stray current

[0022] The traction power supply system of the existing urban rail transit is basically a DC traction power supply system that uses overhead catenary or contact rail (three-rail) power supply, and the running rail as the return path. Due to the limitations of the operating environment, economy and other factors, it is impossible for the running rail to be completely insulated from the ballast bed structure, so the steel rail inevitably leaks current to the ballast bed, station, and tunnel structure, that is, stray current.

[0023] In the actual project, the rails are installed by the insulation method, and insulating pads and insulating sleeves are added at each rail installation point. The rail return system is a suspension system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com