OLED display panel and preparation method thereof

A display panel and organic layer technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems that the display area is vulnerable to water and oxygen erosion and affect product reliability, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Such as Figure 4 As shown, the present invention also provides a method for preparing an OLED display panel, comprising the following steps:

[0043] S10, providing a substrate, defining a wall area on the substrate;

[0044] S20, preparing several layers of inorganic layers, at least one first metal block, and several layers of organic layers on the substrate, wherein the first metal block is located in the barrier area;

[0045] S30, forming a via hole in the retaining wall region, the via hole passing through several layers of the inorganic layer and several layers of the organic layer, and the via hole exposes a side surface of the first metal block;

[0046] S40, using an etchant to etch the first metal block to form a groove on the sidewall of the via hole;

[0047] S50, forming a light emitting layer on the organic layer, wherein the light emitting layer is discontinuous at the groove of the via hole;

[0048] S60, forming an encapsulation layer on the organi...

Embodiment 1

[0053] Such as image 3 As shown, this embodiment provides an OLED display panel 100, including a substrate 10, several inorganic layers disposed on the substrate, a light emitting layer 80 disposed on the organic layer, and a light emitting layer disposed on the light emitting layer. 80 on the packaging layer, and the via 101.

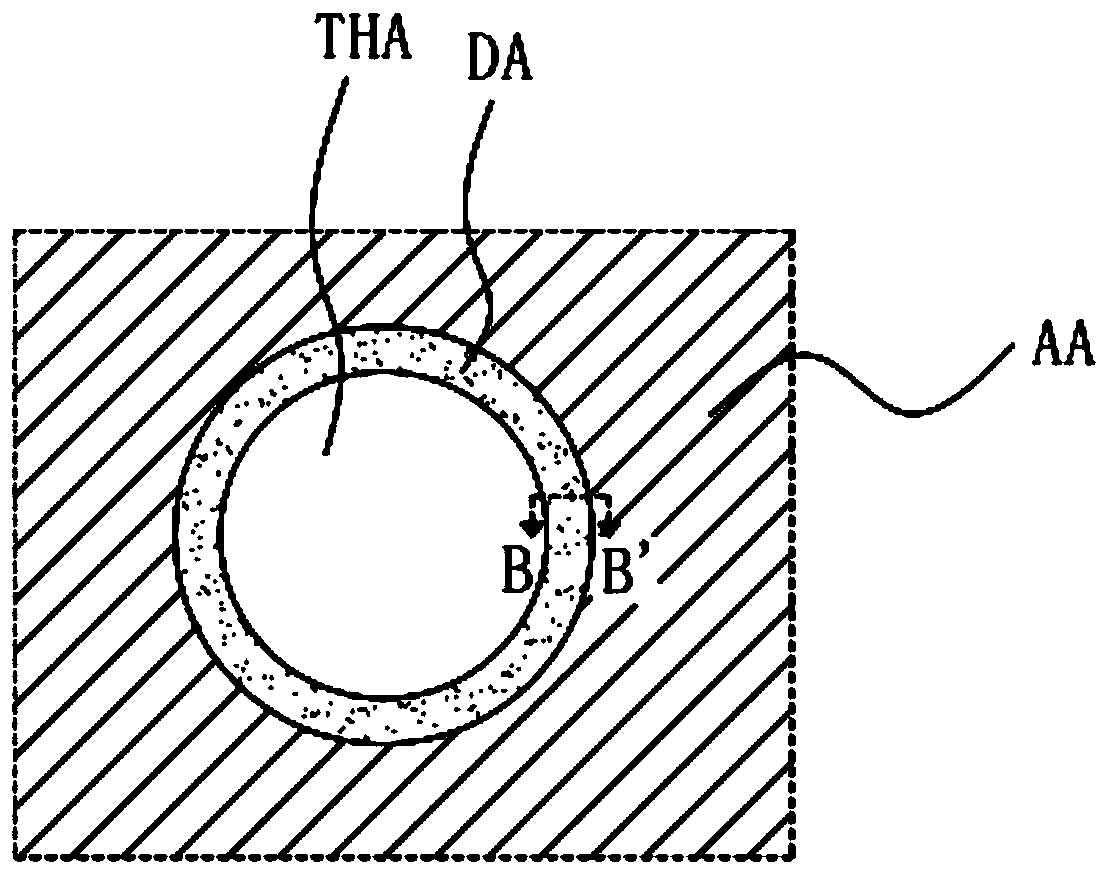

[0054] The OLED display panel 100 defines a display area AA, a through hole area THA, and a wall area DA disposed between the display area AA and the through hole area THA.

[0055] The display area AA is used to realize color display, the through hole area THA is used to place a camera, and the wall area DA is used to disconnect the light emitting layer 80 so that the light emitting layer 80 is on the substrate 10 is discontinuous, so as to prevent water and oxygen from corroding the part of the light emitting layer 80 located in the display area.

[0056] The via hole 101 is disposed in the retaining wall area DA, the via hole 101 penetrates throu...

Embodiment 2

[0089] The first metal block 102' in this embodiment is prepared on the same layer as the source and drain electrodes, and the position of the groove 102 is different from that in Embodiment 1. The groove 102 in this embodiment is prepared by In the case of the drain metal, the patterned metal block in the wall area DA is retained, and the metal block is etched away to be formed.

[0090] Such as Figure 12 As shown, the two grooves 102 in this embodiment are arranged at intervals between the interlayer insulating layer 40 and the flat layer 50, the depth of the grooves 102 is 730 nanometers, and other structures are the same as those in the embodiment. One is the same, so I won't repeat them here.

[0091] Such as Figure 9As shown, when depositing the source-drain metal film layer on the interlayer insulating layer 40, the two patterned metal blocks (namely the first metal block 102') in the barrier area DA are reserved.

[0092] Such as Figure 10 As shown, after the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com