Preparation method of superhydrophobic superparamagnetic silicone resin composite coating

A composite material and silicone resin technology, applied in coatings, magnetic coatings, etc., can solve problems such as poor adhesion, poor weather resistance of polymers, and easy particle agglomeration to achieve extended service life, good mechanical properties, and improved dispersion. and compatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

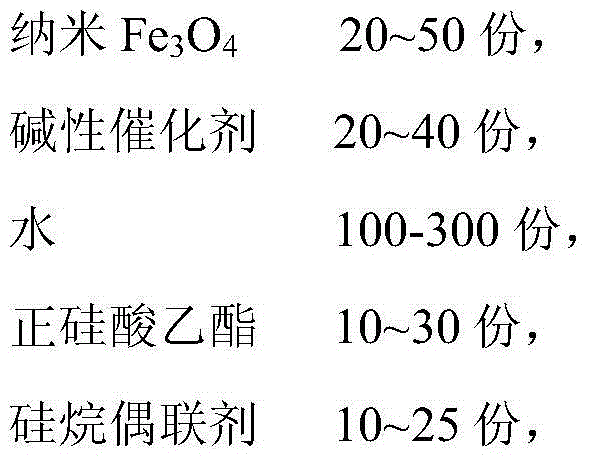

[0032] (1) Preparation of modified Fe 3 o 4 particle

[0033] In parts by mass, 50 parts of nano-Fe 3 o 4 , 40 parts of ammonia water and 300 parts of water are added to the reaction kettle with a stirring paddle, stirred at a speed of 500 rpm for 30 minutes, the temperature of the water bath is slowly raised to 80°C, and 30 parts of ethyl orthosilicate is added within 4 hours After the slow addition, add 25 parts of methacryloxypropyltrimethoxysilane slowly within 4 hours, keep stirring for 6 hours after the dropwise addition is completed, then separate the prepared solution under an external magnetic field, remove the upper layer, The particles in the lower layer were alternately washed with absolute ethanol and distilled water for 5 times, and then dried in a blast drying oven at 60°C for 48 hours to obtain modified Fe 3 o 4 particle.

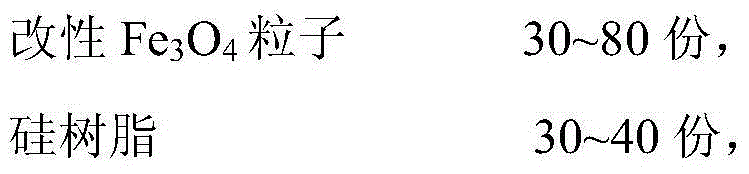

[0034](2) Preparation of superhydrophobic superparamagnetic silicone resin composites

[0035] 80 parts of modified Fe 3 o 4 Parti...

Embodiment 2

[0038] (1) Preparation of modified Fe 3 o 4 particle

[0039] In parts by mass, 40 parts of nano-Fe 3 o 4 , 35 parts of potassium hydroxide and 250 parts of water were added to the reaction kettle with a stirring paddle, stirred at a speed of 450 rpm for 45 minutes, and the temperature of the water bath was slowly raised to 70°C, and 25 parts of ethyl orthosilicate was added to the After adding slowly within 2.5 hours, add 15 parts of tridecafluorooctyltrimethoxysilane slowly within 3 hours, keep stirring for 4 hours after the dropwise addition is completed, then separate the prepared solution under an external magnetic field, and remove the upper layer , the lower particles were alternately washed with absolute ethanol and distilled water for 4 times, and then dried in a blast drying oven at 50°C for 35 hours to obtain modified Fe 3 o 4 particle.

[0040] (2) Preparation of superhydrophobic superparamagnetic silicone resin composites

[0041] 60 parts of modified Fe 3...

Embodiment 3

[0044] (1) Preparation of modified Fe 3 o 4 particle

[0045] In parts by mass, 30 parts of nano-Fe 3 o 4 , 30 parts of sodium hydroxide and 200 parts of water are added to the reaction kettle with a stirring paddle, stirred at a speed of 300 rpm for 60 minutes, the temperature of the water bath is slowly raised to 75 °C, and 20 parts of ethyl orthosilicate After slowly adding within 3 hours, slowly add 20 parts of hexadecyltrimethoxysilane within 3.5 hours, keep stirring for 3 hours after the dropwise addition, and then separate the prepared solution under an external magnetic field, remove the upper layer, The particles in the lower layer were alternately washed with absolute ethanol and distilled water for 3 times, and then dried in a blast drying oven at 55°C for 24 hours to obtain modified Fe 3 o 4 particle.

[0046] (2) Preparation of superhydrophobic superparamagnetic silicone resin composites

[0047] 50 parts of modified Fe 3 o 4 Particles, 30 parts of methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com