Preparation method of chitin aerogel

A chitin and aerogel technology, which is applied in the field of chitin aerogel preparation, can solve the problems of difficulty in separation, purification and recovery, and high production costs, and achieves the advantages of environmental protection and operator health, low cost, and easy operation. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

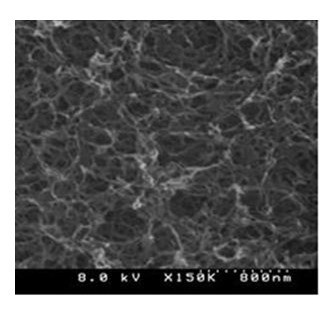

Embodiment 1

[0035] The commercially available chitin was soaked in 5wt% dilute HCl at room temperature for 12 hours, filtered and washed with water, soaked in 4wt% NaOH aqueous solution for 12 hours, and then dried to obtain chitin powder with an acetylation degree of 92%. Pre-cool the mixed solvent of 11g NaOH, 4g urea and 85g water to -12°C, add 6g chitin powder and stir evenly, then keep it at -20°C for 12h. Thaw at room temperature to obtain a transparent chitin solution. A 1mm thick chitin solution was obtained by casting on a glass plate, immersed in 5wt% H 2 SO 4 Put it in the aqueous solution for 10 minutes to make it gel, wash it with water and replace it with absolute ethanol, and pass through supercritical CO 2 Drying (temperature 40°C, pressure 100kg / cm 2 ) to prepare chitin aerogels. The specific surface area of chitin airgel is 376m2 through nitrogen adsorption-desorption test 2 / g, porosity 89%, density 0.24g / cm 3 .

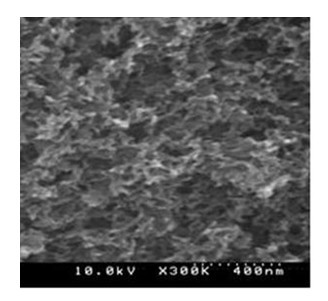

Embodiment 2

[0037] After the chitin hydrogel in Example 1 was replaced with tert-butanol, the chitin aerogel was obtained through freeze-drying, and the other steps were the same. The specific surface area of chitin aerogel is 336m through nitrogen adsorption-desorption test 2 / g, porosity 87%, density 0.22g / cm 3 .

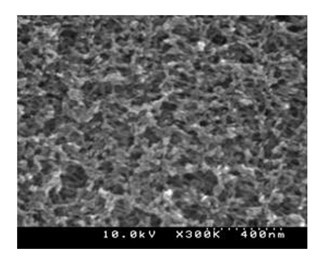

Embodiment 3

[0043] The commercially available chitin was soaked in 5wt% dilute HCl at room temperature for 12 hours, filtered and washed with water, soaked in 4wt% NaOH aqueous solution for 12 hours, and then dried to obtain chitin powder with an acetylation degree of 92%. Pre-cool the mixed solvent of 2g NaOH, 20g urea and 78g water to -12°C, add 0.5g chitin powder and stir evenly, then keep it at -20°C for 12h. Thaw at room temperature to obtain a transparent chitin solution. A chitin solution with a thickness of 1mm was obtained by casting on a glass plate. The chitin solution was immersed in a 5wt% HCl aqueous solution for 10 minutes to make it gel, washed with water and then replaced with anhydrous methanol. 2 Drying (temperature 40°C, pressure 100kg / cm 2 ) to prepare chitin aerogels. The specific surface area of chitin aerogel is 375m through nitrogen adsorption-desorption test 2 / g, porosity 97%, density 0.04g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com