Polymer nanomicrosphere product with uniform and controllable size and preparation method thereof

A polymer and nano-micro technology, applied in the field of polymer nano-microsphere products and their preparation, can solve the problems of slow preparation speed of emulsion, difficult preparation, large interfacial tension between dispersed phase and microporous membrane, etc. The effect of controllable structure and shape, uniform and controllable size, and fast preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

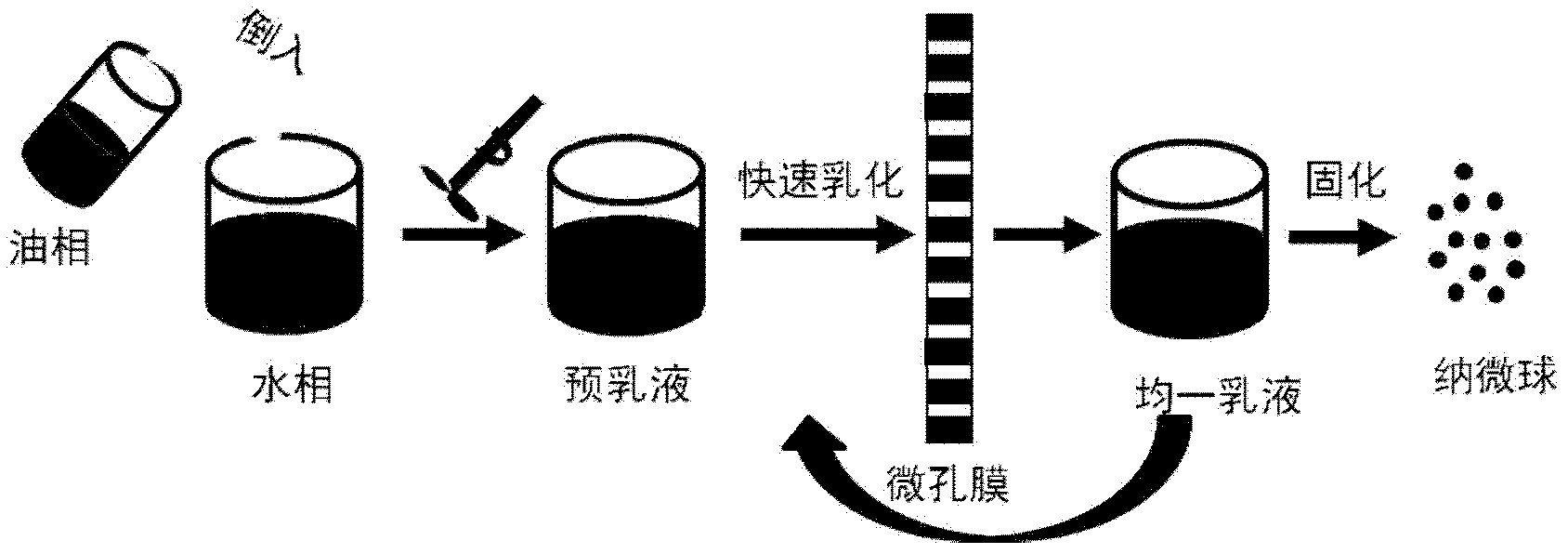

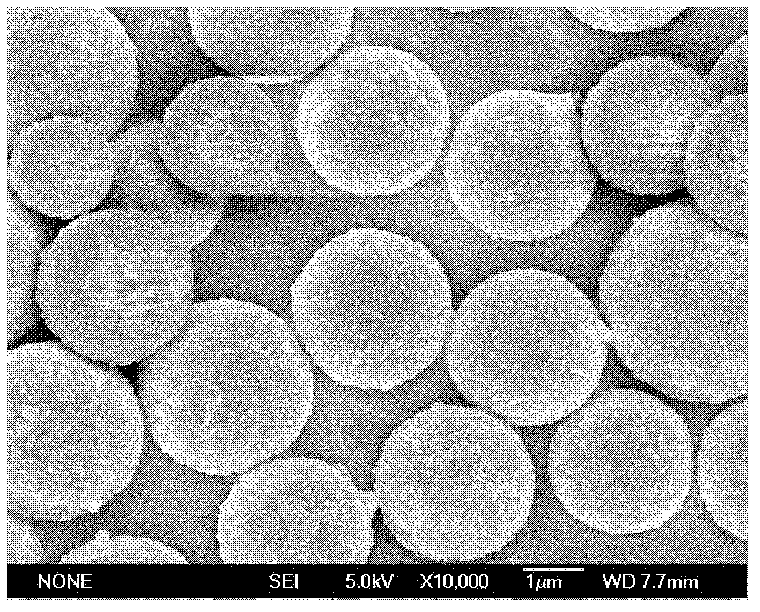

[0069] Embodiment 1 (the aperture of microporous membrane is 2.8 micron, and structure is solid, and monomer is ST)

[0070] The microporous membrane with a pore size of 2.8 μm was placed in deionized water for 30 minutes and then installed in a matching membrane emulsifier for use. Accurately measure 150ml of deionized water, weigh 1.8g of PVA, 0.0003g of SDS and 0.0045g of Na 2 SO 4 and other additives were dissolved in deionized water to form a water phase for later use. 0.5g BPO was completely dissolved in 20g ST to form an oil phase. Add the prepared oil phase into the water phase, and stir at 300 rpm for 10 minutes with mechanical stirring to form a pre-emulsion. Then, the obtained pre-emulsion is quickly poured into the storage tank of the membrane emulsifier, and under a nitrogen pressure of 0.95MPa, it is quickly passed through a microporous membrane with a uniform pore size to obtain an O / W type emulsion with a relatively uniform particle size. The emulsion was u...

Embodiment 2

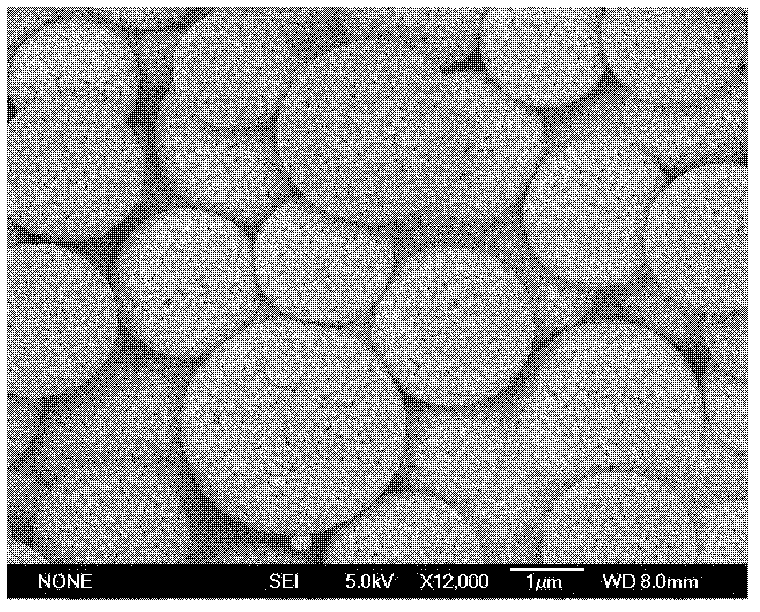

[0071] Embodiment 2 (the aperture of microporous membrane is 2.8 microns, and structure is microporous, and monomer is ST)

[0072] A microporous membrane with the same aperture as in Example 1 and 150 ml of aqueous phase solution were used, and 10 g of n-heptane (HP) was added to the same oil phase to form an oil phase. Add the prepared oil phase into the water phase, and stir at 300 rpm for 10 minutes with mechanical stirring to form a pre-emulsion. Then, the obtained pre-emulsion is quickly poured into the storage tank of the membrane emulsification device, and under a nitrogen pressure of 1.05MPa, it is quickly passed through a microporous membrane with a uniform pore size to obtain an O / W type emulsion with a relatively uniform particle size. The emulsion was used as a pre-emulsion to pass through the microporous membrane again under the nitrogen pressure of 1.05MPa, and the emulsification was repeated 5 times, and finally an O / W emulsion with uniform particle size was ob...

Embodiment 3

[0073] Embodiment 3 (the aperture of microporous membrane is 2.8 microns, and structure is depression, and monomer is DVB)

[0074] A microporous membrane with the same pore size as in Example 1 was used. Accurately measure 200ml of deionized water, weigh 1.2g of PVA, 0.008g of SDS and dissolve in deionized water to form a water phase for later use. 1.1 g of BPO was completely dissolved in 28 g of DVB, 11 g of hexadecane (HD) to form an oil phase. Add the prepared oil phase into the water phase, and stir at 500 rpm for 10 minutes with mechanical stirring to form a pre-emulsion. Then, the obtained pre-emulsion is quickly poured into the storage tank of the membrane emulsification device, and under a nitrogen pressure of 1.1 MPa, it is quickly passed through the microporous membrane to obtain an O / W type emulsion with a relatively uniform particle size, and the obtained emulsion is used as a pre-emulsion. The emulsion passed through the microporous membrane again under a nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com