Method for treating coal bed gas produced water by combining pre-oxidation aerated oxidation with capacitive deionization

A technology of capacitive deionization and aeration oxidation, which is applied in oxidation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and other problems to achieve the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, desalination treatment is carried out by pure brine, the concentration of brine is 1000mg / L, the volume of water sample is 500mL, and two carbon electrodes with an area of 300mm×500mm are used for desalination treatment. The voltage across the electrodes was 2.0V, and after 30min of electro-adsorption treatment, the final brine concentration was 126mg / L.

Embodiment 2

[0025] In this example, the electrosorption test is carried out on heavy metal copper ions. The concentration of copper ions is 200mg / L, the volume of water sample is 500mL, and two carbon electrodes with an area of 300mm×500mm are used for desalination treatment. The voltage across the electrodes was 2.0V, and after 30min of electro-adsorption treatment, the final brine concentration was 0.1mg / L.

Embodiment 3

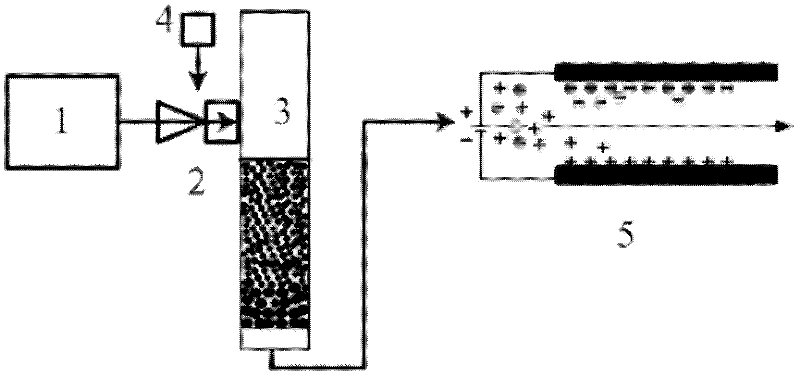

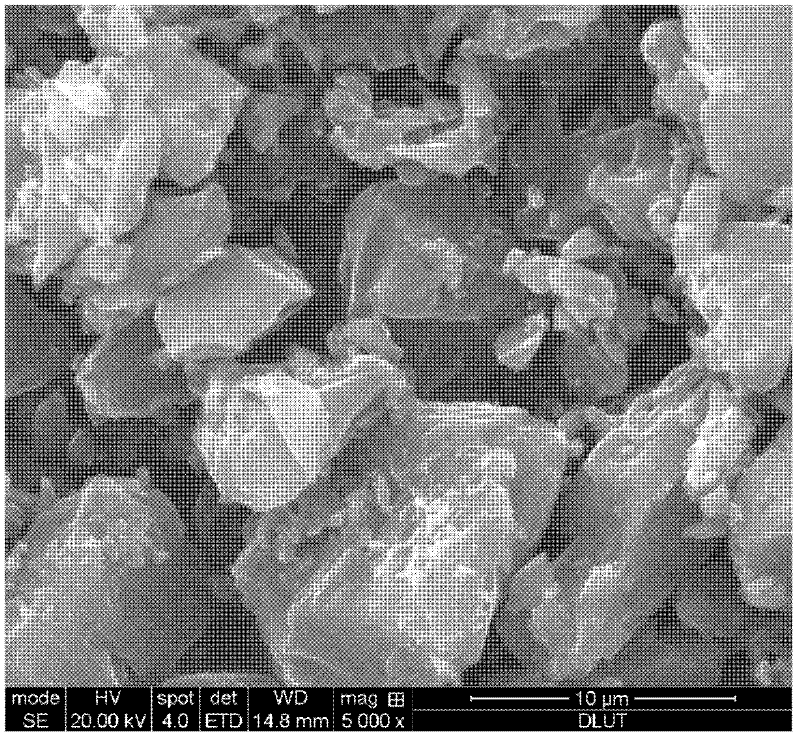

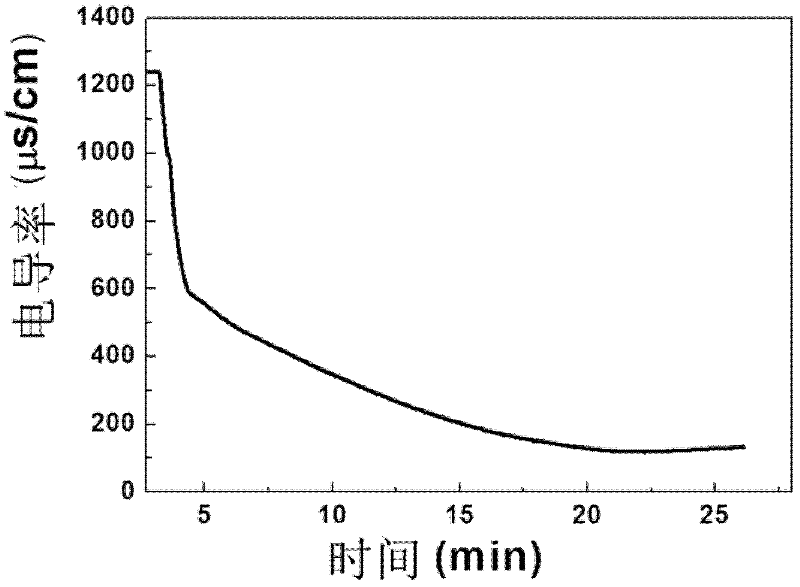

[0027] In this example, the water produced by coalbed methane is simulated by self-made, and the water quality conditions are shown in Table 1. See the processing flow chart figure 1 , mainly includes three processing steps: using air to perform microporous air aeration treatment on the simulated water quality, the water sample volume is 110mL, the aeration flow rate is 20mL / min, and the aeration time is 1h; then it is filtered through quartz sand media; finally, the The filtered produced water passes through the capacitive deionization module with an operating voltage of 1.6V and a circulation flow rate of 5mL / min. The total conductivity efflux curves of different ions are shown in figure 2 shown. The water quality analysis at the two different treatment stages is shown in Table 2. It can be seen that this process can realize the safe discharge of coalbed methane mining drainage with high iron content.

[0028] Table 1 Influent water quality (unit: mg / L)

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com