Method for compensating rebounding error of automobile cover panel based on numerical simulation

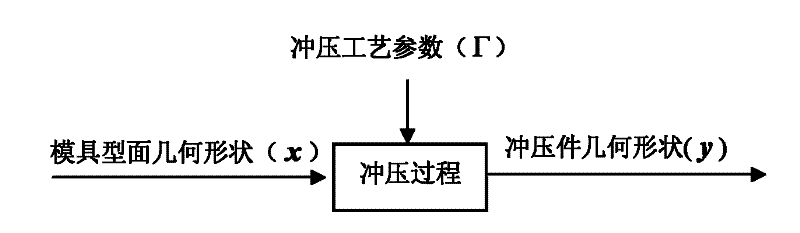

A technology for automobile cover parts and numerical simulation, which is applied in the field of sheet metal stamping and forming, which can solve the problems of long cycle time, inability to determine the point-to-point correspondence between the die profile and stamping parts, and inability to measure the shape of stamping parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

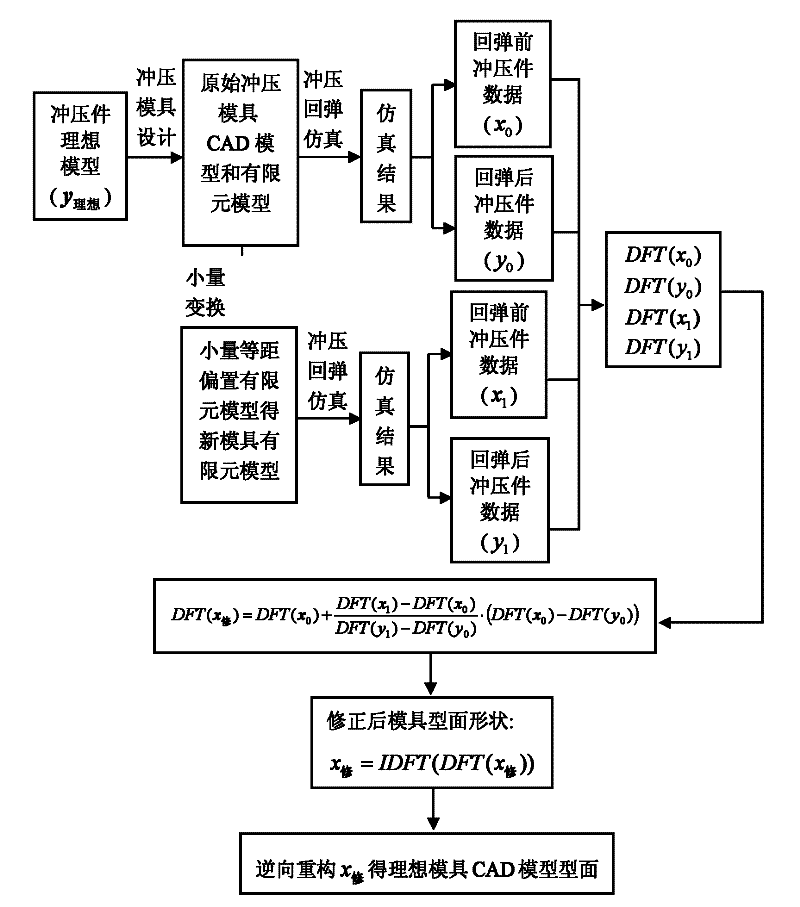

[0052] Examples, see figure 2 As shown, a kind of automobile panel springback error compensation method based on numerical simulation of the present invention comprises the following steps:

[0053] A. Construct an ideal model of a stamping part in the computer, and obtain the profile data of the ideal stamping part, marked as y 理想 ;

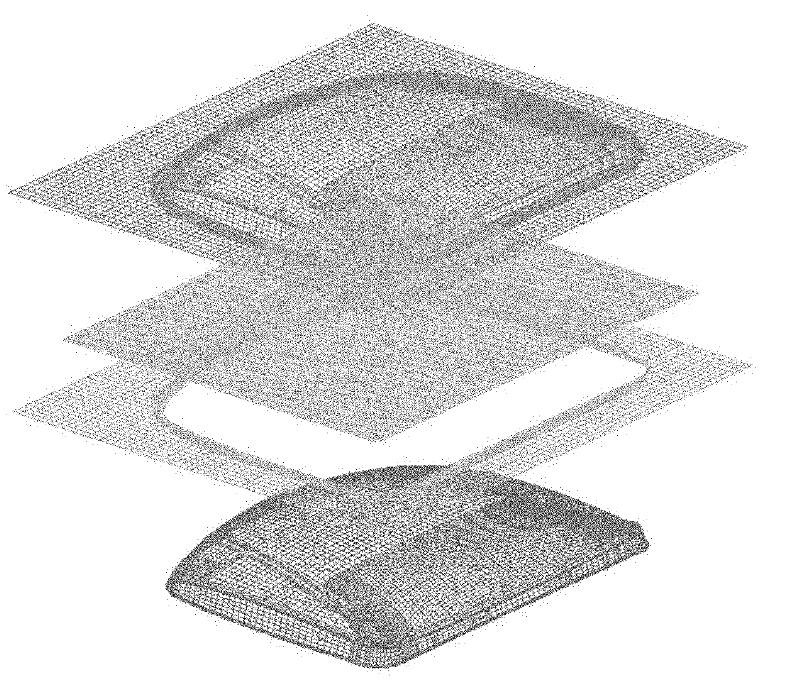

[0054] B. Use numerical simulation software in the computer to design and process the stamping die for the ideal model of the above-mentioned stamping parts, so as to obtain a finite element model of the original stamping die;

[0055] C. Carry out a small amount of isometric offset processing to the finite element model of the above-mentioned original stamping die in the computer, thereby obtaining a new mold finite element model with a small amount of isometric offset;

[0056] The offset amount of the small amount of equidistant offset is less than 0.5mm in the outward or inward offset distance, for example, a small amount of equidistant o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com