High-strength steel plate with yield strength 1,000 MPa and production method thereof

A yield strength and toughness steel plate technology, applied in the field of high-strength and tough steel plate production, can solve the problems of lack of scientific control of original billet quality, limitation of steel composition and production conditions, difficulty of ultra-high-strength steel plate, etc. Large specification coverage and good water flow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

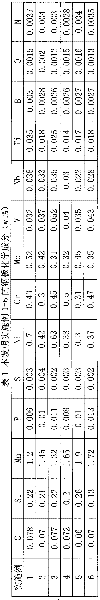

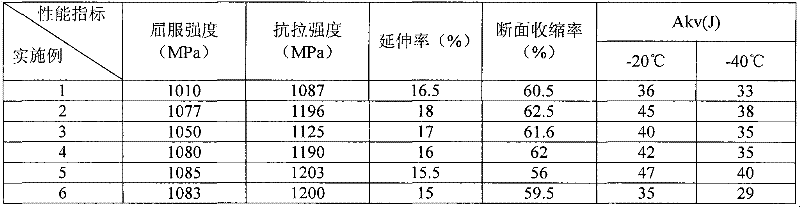

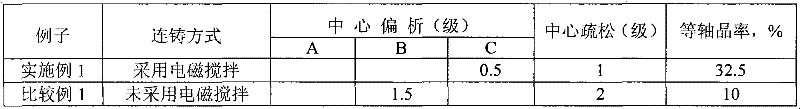

Embodiment 1

[0037] According to the composition shown in Table 1, pretreatment of molten iron, converter smelting, LF+RH refining, under the action of electromagnetic stirring (396A, 380A, 5Hz), casting into 230mm thick continuous casting slab. Heat the continuous casting slab to 1180°C, keep it warm for 180min, carry out the first-stage rolling in the rough rolling mill, the rolling start temperature is 1120°C, when the thickness of the rolled piece is 130mm, swing it beside the finish rolling mill and wait for the temperature to 900°C, then Carry out the second stage rolling. The final rolling temperature is 866°C. The thickness of the finished steel plate is 50mm. After rolling, continue to relax and wait for 11s, then directly quench the steel plate, rapidly cool to 400°C at a rate of 12°C / s, and stack slowly to room temperature after off-line. The tempering temperature of the steel plate is 500°C, and the holding time is 150min.

Embodiment 2

[0039] The implementation is as in Example 1, wherein the electromagnetic stirring parameters are: 367A, 349A, 5Hz. The thickness of the casting slab is 200mm. The continuous casting slab is heated to 1150°C and held for 200min. The rolling temperature of the second stage is 923°C, the final rolling temperature is 885°C, and the thickness of the finished steel plate is 30mm. After rolling, the steel plate is directly quenched after relaxing for 15s. The cooling rate of the steel plate is 20°C / s, and the final cooling temperature is 380°C. The tempering temperature is 550°C, and the holding time is 90 minutes.

Embodiment 3

[0041] The implementation is as in Example 1, wherein the electromagnetic stirring parameters are: 387A, 369A, 5Hz. The thickness of the continuous casting slab is 230mm. The continuous casting slab is heated to 1180°C and held for 150 minutes. The rolling temperature of the first stage is 1125°C, and the thickness of the waiting temperature is 110mm. The rolling temperature of the second stage is 905°C and the final rolling temperature is 871°C. The thickness of the steel plate is 40mm. After rolling, the steel plate is directly quenched after relaxing for 17s. The cooling rate of the steel plate is 16°C / s, and the final cooling temperature is 385°C. The tempering temperature is 500°C, and the holding time is 120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com