Multi-component bone tissue engineering scaffold material and preparation method thereof

A technology of bone tissue engineering and scaffold materials, applied in medical science, prosthesis, etc., can solve problems such as easy aggregation and uneven dispersion of HA particles, and achieve the effect of promoting repair, good application prospects, and simple method process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

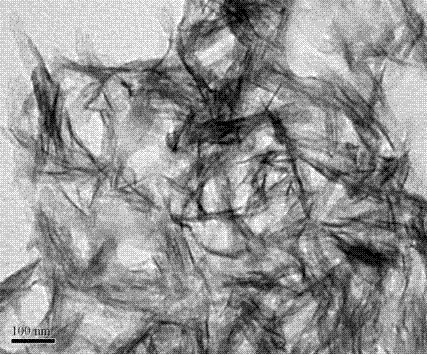

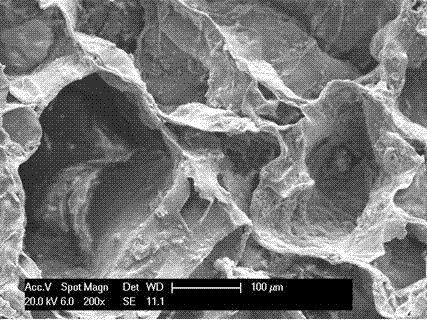

[0026] Dissolve 1 g of pectin in 100 mL of deionized water to prepare a pectin solution with a concentration of 1% (w / v); dissolve 1 g of chitosan in 100 mL of 1% acetic acid solution to prepare a concentration of 1% ( w / v) acetic acid solution of chitosan; 4.723g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) Dissolved in pectin solution, 1.653g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) be dissolved in the chitosan solution; the above-mentioned chitosan solution containing phosphate is added dropwise in the pectin solution containing calcium ions, wherein the ratio of calcium ions to the amount of phosphate radicals is 1.67, and the mass concentration is 5% NaOH solution was used to adjust the pH value to 9, stirred for 6 hours, and allowed to stand still for 48 hours to maintain the pH value of 9. Centrifuge, collect the solids, and rinse with deionized water until the pH value of the solution is 7, pre-freeze at -20 °C, and then freeze-dry to obtain nano-hydroxyapatite / chi...

Embodiment 2

[0029] Dissolve 1 g of pectin in 100 mL of deionized water to prepare a pectin solution with a concentration of 1% (w / v); dissolve 1 g of chitosan in 100 mL of 1% acetic acid solution to prepare a concentration of 1% ( w / v) acetic acid solution of chitosan; 2.362g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) Dissolved in pectin solution, 0.827g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2O) dissolved in chitosan solution; the chitosan solution containing phosphate is added dropwise to the pectin solution containing calcium ions, wherein the ratio of calcium ions to phosphate radicals is 1.67, and the mass concentration is 5 % NaOH solution was used to adjust the pH to 9, stirred for 6 hours, and allowed to stand for 48 hours to maintain the pH at 9. Centrifuge, rinse with deionized water until the pH of the solution is 7, pre-freeze at -20 °C, and freeze-dry to obtain nano-hydroxyapatite / chitosan-pectin complex (nHCP).

[0030] Dissolve 1g of chitosan in 50mL of acetic acid with...

Embodiment 3

[0032] Dissolve 1g of pectin in 100mL of deionized water to prepare a pectin solution with a concentration of 1% (w / v); dissolve 0.5g of chitosan in 100mL of 1% acetic acid solution to prepare a concentration of 0.5% (w / v) acetic acid solution of chitosan; 4.723g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) Dissolved in pectin solution, 1.653g sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) dissolved in chitosan solution; the chitosan solution containing phosphate is added dropwise to the pectin solution containing calcium ions, wherein the ratio of calcium ions to phosphate radicals is 1.67, and the mass concentration is 5 % NaOH solution was used to adjust the pH to 9, stirred for 6 hours, and allowed to stand for 48 hours to maintain the pH at 9. Centrifuge, rinse with deionized water until the pH of the solution is 7, pre-freeze at -20 °C, and freeze-dry to obtain nano-hydroxyapatite / chitosan-pectin complex (nHCP).

[0033] Dissolve 1g of chitosan in 50mL of acetic acid with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com