Method for preparing rare earth-containing seamless steel tube for petroleum cracking

A seamless steel pipe, oil cracking technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high compressive strength and corrosion resistance of pipelines, harsh operating conditions of cracking devices, and high concentration, and achieve low cost. , good promotion value, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

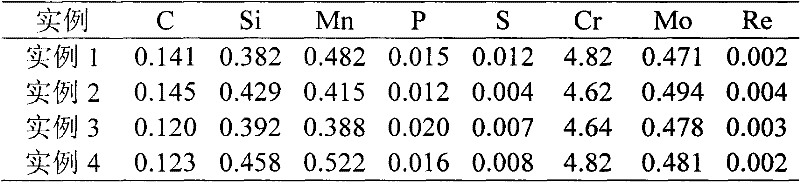

[0011] The smelting production process of steel is: molten iron→converter smelting→LF refining→VD degassing→round billet continuous casting. Converter smelting adopts desulfurized molten iron, deoxidation and alloying of silicomanganese, ferromanganese and ferrochrome alloys, and the whole process is blown with argon according to normal refining; The chemical composition of each example is shown in Table 1.

[0012] Each example composition of table 1 (mass percentage / %)

[0013]

[0014] The rolling process of seamless steel pipe is: round billet → sawing → heating → piercing → pipe rolling → tension reduction → sampling → cooling → cutting head and tail → straightening → inspection → packaging → weighing → storage. The temperature of the round billet is 1260-1280°C when it is pierced; the temperature when it is rolled is 1200-1220°C; Apply the Ф180MPM unit to roll the seamless steel pipe with the specification of Ф245mm×16mm.

[0015] The heat treatment process of roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com