Method for treating organic amine industrial waste water by Fenton-like oxidation-flocculation

A technology for industrial wastewater and organic amines, which is applied in chemical instruments and methods, natural water treatment, and multi-stage water/sewage treatment. subsidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

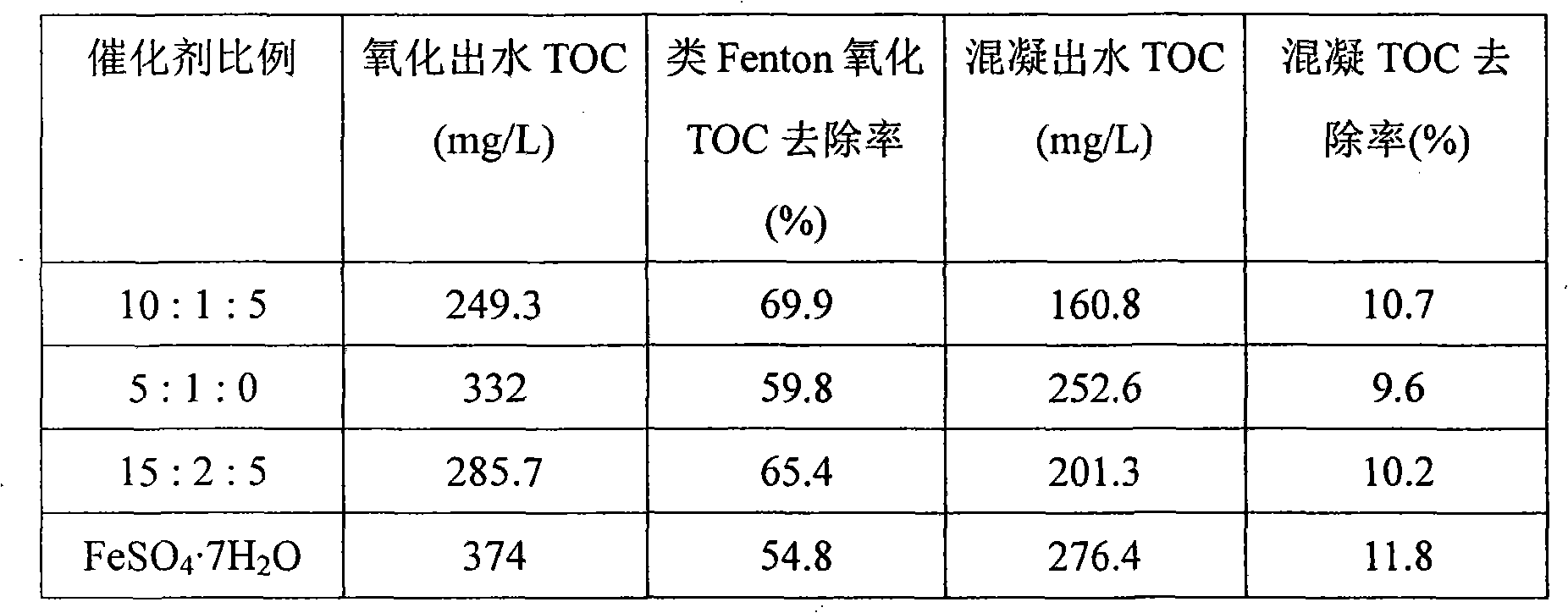

[0019] Embodiment 1: The inventive method handles triethanolamine wastewater

[0020] The total organic carbon TOC of a certain triethanolamine wastewater is 827mg / L, and the treatment process is as follows: the wastewater enters the reaction tank, the temperature of the wastewater is adjusted to 30°C, and the pH of the wastewater is adjusted to 3.5 by adding sulfuric acid. h 2 o 2 (30%) is added in an amount of 3.4% of waste water quality, H 2 o 2 (30%) is 11:1 with catalyst mass ratio, and the addition of catalyst is 3g / L, and catalyst FeSO 4 ·7H 2 O: CuSO 4 :MnSO 4 Take three different ratios of 10:1:5, 5:1:0, and 15:2:5, and use FeSO alone 4 ·7H 2 O served as a control. After the catalyst was completely dissolved, hydrogen peroxide was added dropwise in batches. During the reaction, sulfuric acid or sodium hydroxide was added to keep the pH stable and stirring was continued. The reaction time was 3 hours. A chemical coagulant is added to the oxidized effluent in ...

Embodiment 2

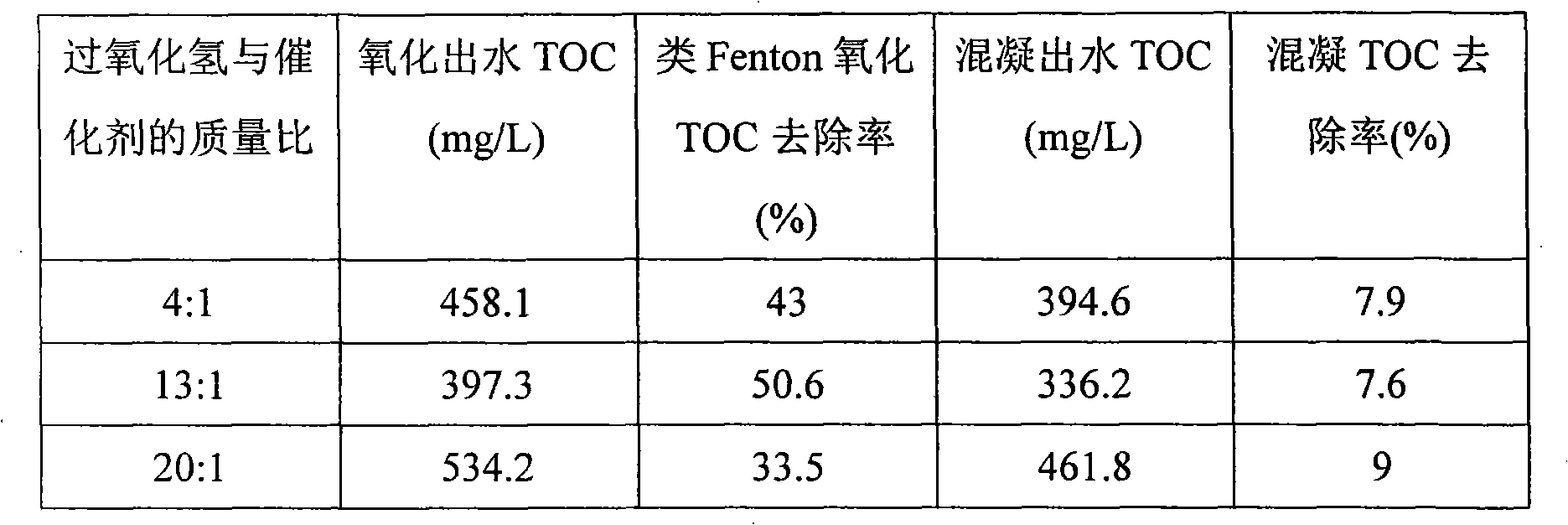

[0023] Implementation example 2: the inventive method handles certain mixed organic amine waste water

[0024] The TOC of an organic amine wastewater is 803.7mg / L, and the characteristic pollutants of the wastewater include ethanolamine, diethanolamine, triethanolamine, dimethylethanolamine, and ethylamine. The treatment process is as follows: the waste water enters the reaction tank, the temperature of the waste water is adjusted to 40°C, and the pH of the waste water is adjusted to 3 by adding sulfuric acid. h 2 o 2 (30%) addition is 3.7% of waste water quality, H 2 o 2 (30%) and catalyst mass ratio are respectively 4: 1, 13: 1, 20: 1, FeSO in the catalyst 4 ·7H 2 O: CuSO 4 :MnSO 4 =10:1:5. The addition amount of catalyst is 9.25g / L, 2.85g / L, 1.85g / L respectively. After the catalyst was completely dissolved, hydrogen peroxide was added dropwise in batches. During the reaction, sulfuric acid or sodium hydroxide was added to keep the pH stable and stirring was continu...

Embodiment 3

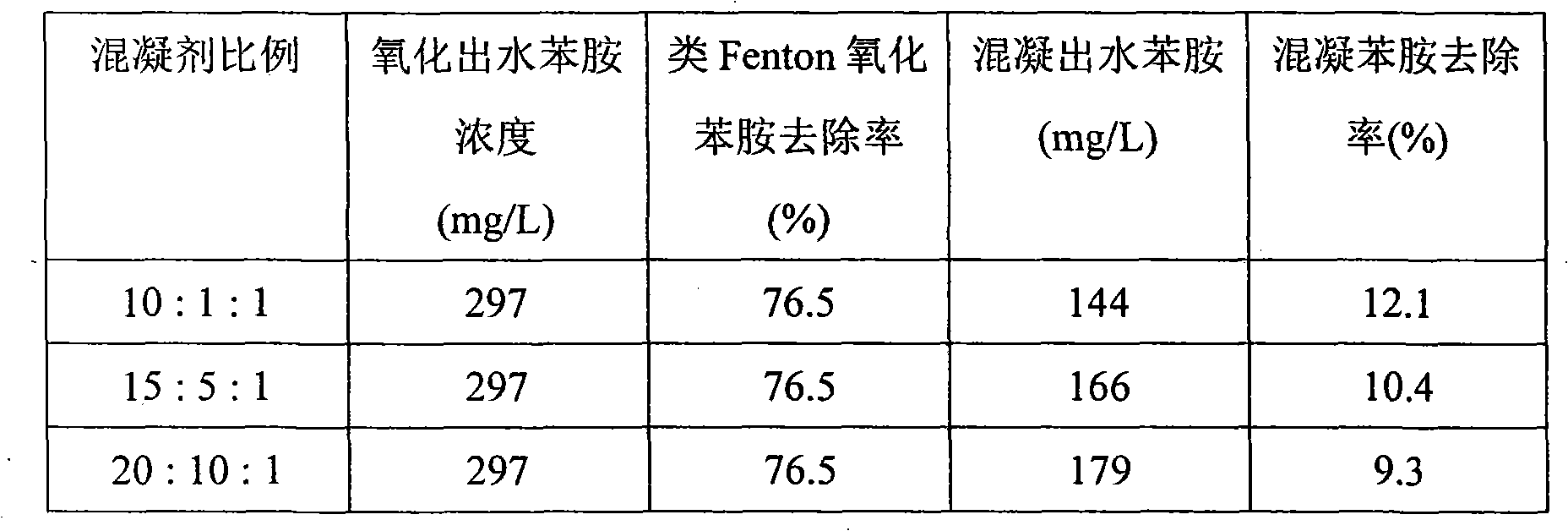

[0027] Implementation example 3: the inventive method handles aniline wastewater

[0028] The mass concentration of an aniline wastewater is 1264mg / L. The treatment process is as follows: the waste water enters the reaction tank, the temperature of the waste water is adjusted to 30°C, and the pH of the waste water is adjusted to 4 by adding sulfuric acid. h 2 o 2 (30%) addition is 2% of waste water quality, H 2 o 2 (30%) is 10:1 with catalyst mass ratio, and the addition amount of catalyst is 2g / L, and in the catalyst FeSO 4 ·7H 2 O: CuSO 4 :MnSO 4 =10:1:1. After the catalyst was completely dissolved, hydrogen peroxide was added dropwise in batches. During the reaction, the pH was kept stable by adding sulfuric acid or sodium hydroxide, and the reaction time was 4 hours. A chemical coagulant is added to the oxidized effluent, the dosage is 1g / L, and the ratio of coagulant ferrous sulfate: ferric sulfate: polyaluminum ferric sulfate is 10:1:1, 15:5:1, 20:10:1 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com