Magnetic polypyrrole/titanium dioxide/clay nano-composite photocatalyst and preparation method thereof

A titanium dioxide and nano-composite technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve complex preparation processes, low product yields, and insufficient treatment problems such as improving the specific surface area and adsorption capacity, simplifying the production process, and eliminating the step of adding acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Add 200 g of deionized water to 20 g of attapulgite, and ultrasonically disperse for 0.5 hour with a JYD650 intelligent ultrasonic cell pulverizer to prepare a slurry with a mass ratio of water to attapulgite of 10:1.

[0024] At 30°C, add the prepared attapulgite slurry to 60 ml with a molar concentration of 2 mol L -1 in an aqueous solution of titanium tetrachloride, stirred evenly, acidified for 30 minutes, heated to raise the temperature of the system to 90° C., and kept for reaction for 3 hours to obtain a titanium dioxide / attapulgite nanocomposite slurry.

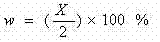

[0025] Cool the titanium dioxide / attapulgite nanocomposite slurry to 10 °C, and use a molar concentration of 2 mol L -1 The pH value of the ammonia solution to adjust the system is 1.5, add 1.2 grams of pyrrole, stir and mix evenly, and add 20 milliliters of it dropwise to the mixed system with a molar concentration of 2mol L while stirring. -1 ferric chloride aqueous solution, and heat preservation...

Embodiment 2

[0029] Example 2: In Example 2, except that attapulgite is replaced by diatomite, other process parameters and operating methods are the same as in Example 1 to obtain magnetic polypyrrole / titanium dioxide / diatomite nanocomposite photocatalyst powder . The mass ratio of titanium dioxide to diatomite in the nanocomposite photocatalyst is 0.4793:1, the mass ratio of polypyrrole to diatomite is 0.06:1, and the mass ratio of ferric oxide to diatomite is 0.2315:1.

Embodiment 3

[0030] Example 3: In Example 3, except that attapulgite was replaced by bentonite, other process parameters and operating methods were the same as in Example 1 to obtain magnetic polypyrrole / titanium dioxide / bentonite nanocomposite photocatalyst powder. The mass ratio of titanium dioxide to bentonite in the nanocomposite photocatalyst is 0.4793:1, the mass ratio of polypyrrole to diatomite is 0.06:1, and the mass ratio of ferric oxide to diatomite is 0.2315:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com