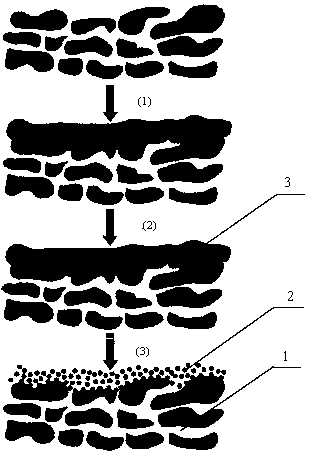

Method for preparing porous inorganic membrane by particle sintering technology assisted by carbon skeleton

An inorganic membrane and inorganic membrane-forming technology, applied in the field of membrane science, can solve problems such as cracks in the membrane layer, complex heat treatment process, and harsh requirements on the substrate, so as to achieve low fluid penetration resistance, avoid cracks or even peeling off, and weaken the stress of the membrane layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Adopt the method of the present invention to prepare porous Al 2 o 3 film, the specific steps are as follows:

[0045] (1)Al 2 o 3 Preparation of coating solution

[0046] Add 16 g of commercial PURAL SB powder into 500 ml of deionized water, mix well to form a suspension, stir and heat to 85 °C and reflux for 2 h, then add 15 ml of nitric acid solution with a concentration of 1.6 mol / L to dissolve the gel, and keep it at 85 Stirring was continued at ℃ for 5 h, then the temperature was naturally lowered, and a stable translucent γ-AlOOH sol was obtained by aging. Finally, the obtained sol was uniformly mixed with a dispersant (aqueous solution of 8 wt.% polyvinyl alcohol (polymerization degree 1750) and 5 wt.% polyethylene glycol-400) at a mass ratio of 6:1 to obtain a γ- 2.6% coating solution of AlOOH particles (particle size 30 nm).

[0047] (2) Coating film

[0048] The substrate used is a porous ceramic substrate with an average pore size of 0.8 μm. Al by di...

Embodiment 2

[0055] Adopt the method of the present invention to prepare porous Al 2 o 3 film, the specific steps are as follows:

[0056] (1) Same as step (1) of Example 1, but the composition of the dispersant in the coating solution used is 3 wt.% polyvinyl alcohol, 2 wt.% methylcellulose, and 4 wt.% polyethyleneimine.

[0057] (2) Same as step (2) of Example 1.

[0058] (3) Anaerobic heat treatment

[0059] The dried substrate was placed in a heating furnace, and the temperature was raised to 600 °C at a rate of 0.5 °C / min, and kept for 3 h, and the heat treatment atmosphere was argon.

[0060] (4) Aerobic heat treatment

[0061] The argon gas was switched to oxygen, at 400 °C, kept for 1 h and then cooled naturally.

[0062] The average pore diameter was measured by mercury intrusion porosimetry to be 0.04 μm.

Embodiment 3

[0064] Adopt method of the present invention to prepare porous silver film, its concrete steps are as follows:

[0065] (1) Preparation of silver coating solution

[0066] 2 g AgNO 3 The solid was dissolved in 50 g of dispersant (aqueous solution of 5 wt.% polyvinyl alcohol and 3 wt.% polyethylene glycol), and 1 ml (85 wt.%) of hydrazine hydrate was added dropwise while stirring. After complete reaction, a solution containing Ag particle (particle size: 150 nm) 2.4% coating solution.

[0067] (2) Coating film

[0068] The substrate used is a porous stainless steel substrate with an average pore size of 2.0 μm. The coating solution was coated on the surface of the substrate by dipping method, and dried for 12 h at a temperature of 30 °C and a humidity of 20%.

[0069] (3) Anaerobic heat treatment

[0070] The dried substrate was placed in a heating furnace, and the temperature was raised to 500 °C at a rate of 1 °C / min, and kept for 1.5 h, and the heat treatment atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com