Fabricated fibrous concrete combined deck structure and construction method thereof

A fiber reinforced concrete and fiber reinforced concrete layer technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of difficult maintenance, long construction period, reduction of concrete strength, etc., to reduce the risk of fatigue cracking, Improves ultimate tensile strength and prevents cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

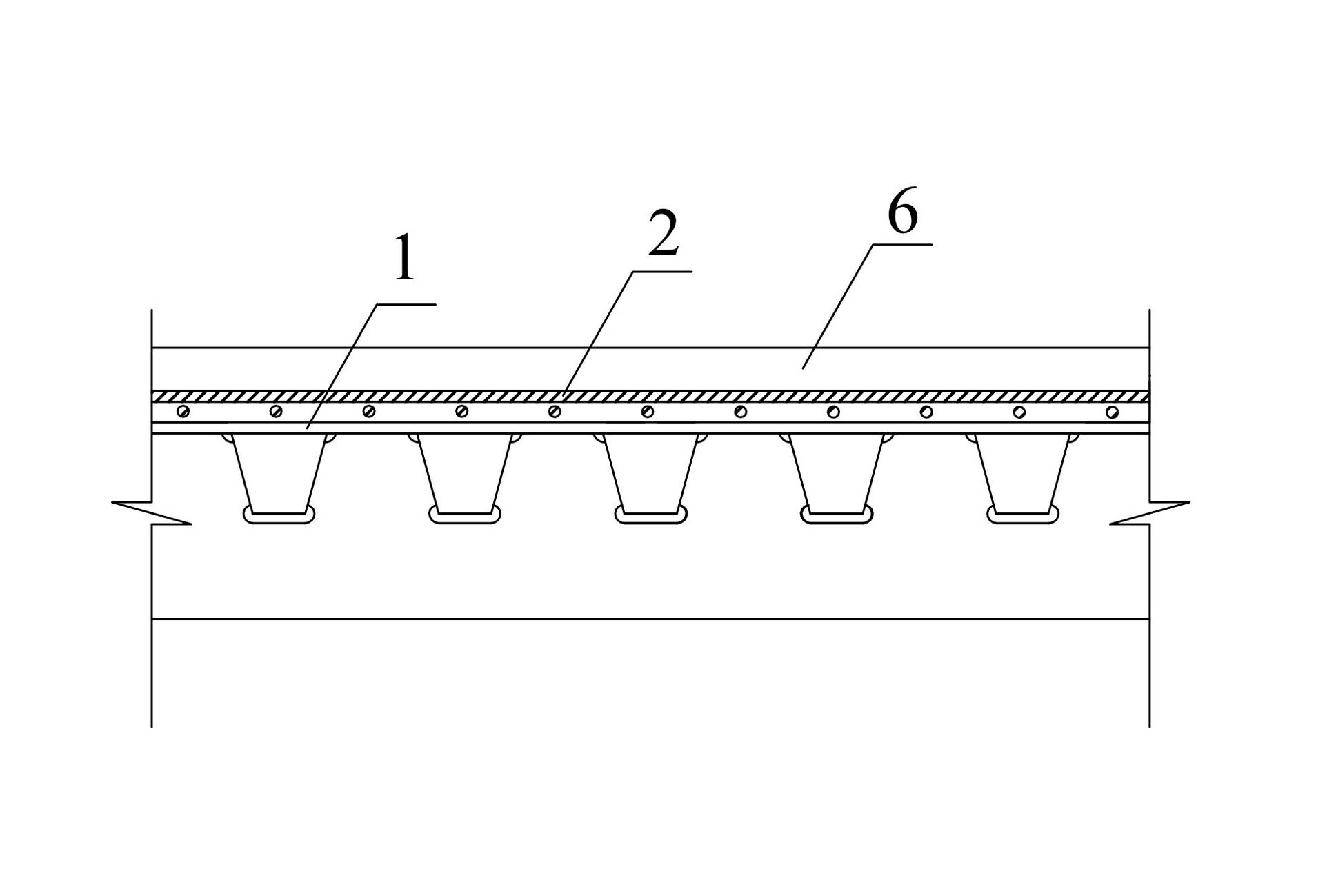

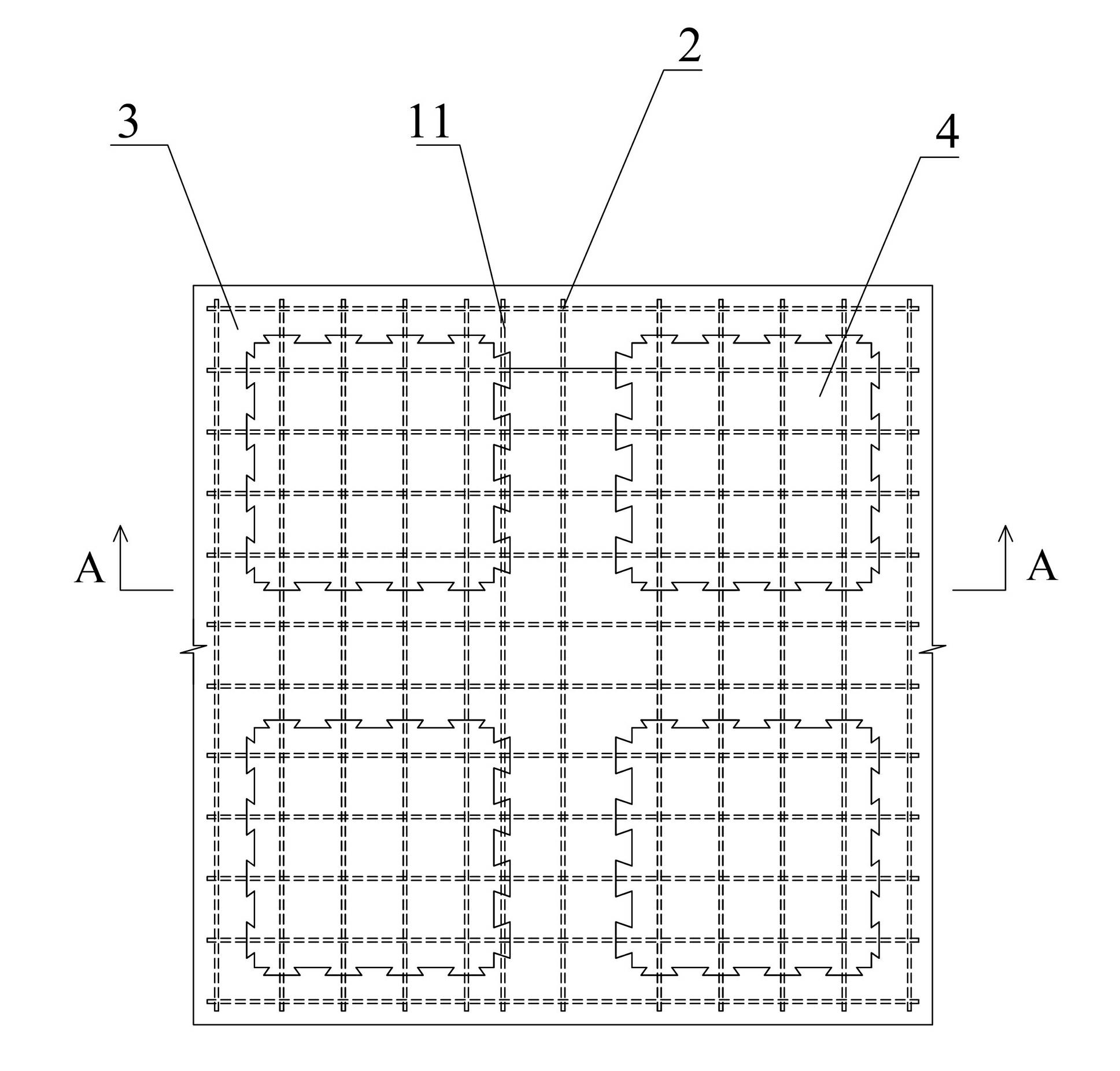

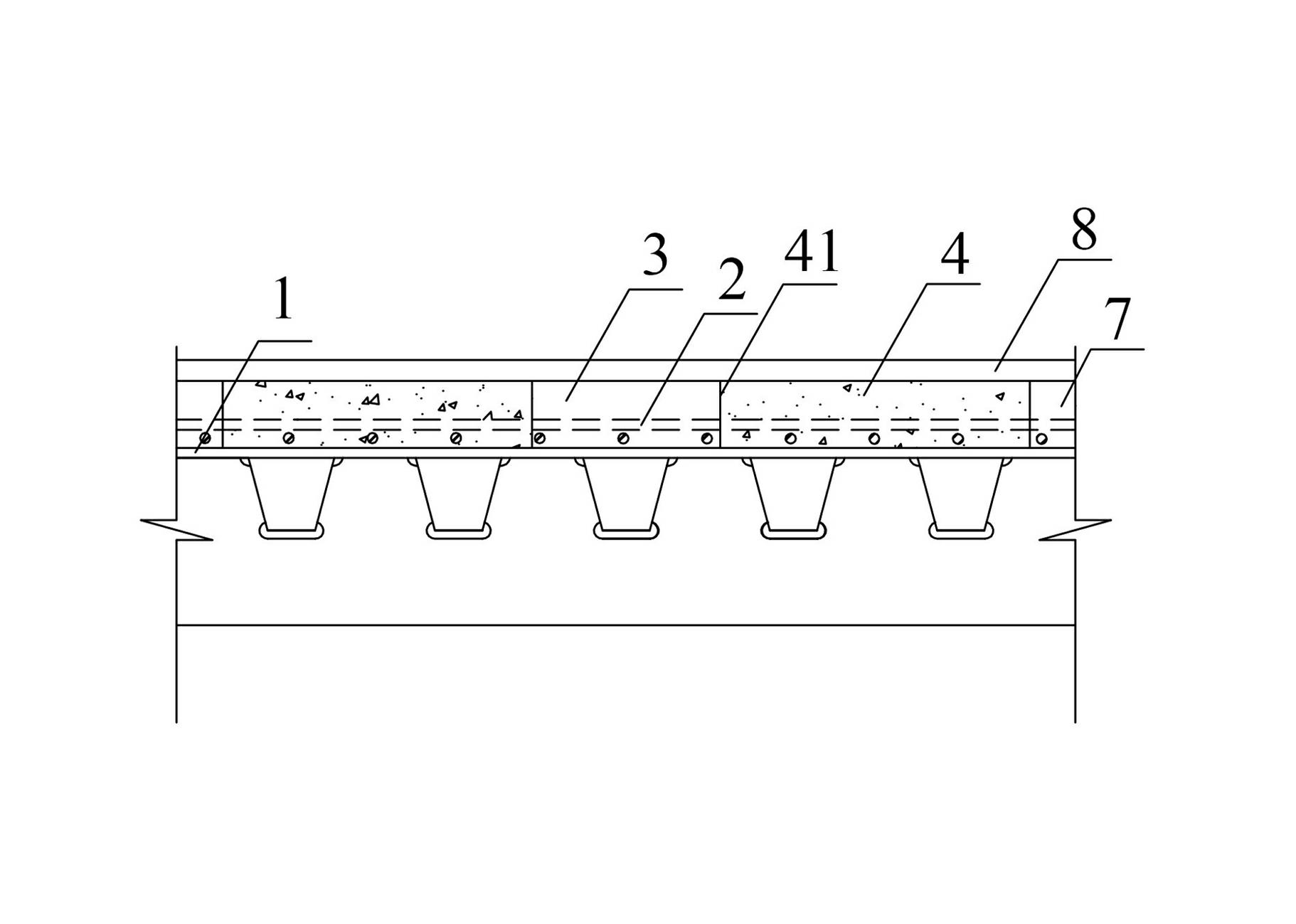

[0041] Kind of like figure 2 , image 3 , Figure 4 The fabricated fiber-reinforced concrete composite bridge deck structure shown includes a steel deck layer 1, and the steel deck layer 1 is covered with a fabricated fiber concrete layer 7 (the fabricated fiber concrete layer 7 of this embodiment) It is mainly made of reactive powder concrete pouring), the joint surface between the steel bridge deck layer 1 and the fabricated fiber concrete layer 7 is flat (the joint surface can also be concave and convex), and the body of the fabricated fiber concrete layer 7 is cast-in-place The fiber concrete layer 3, the cast-in-place fiber concrete layer 3 is embedded with a plurality of prefabricated fiber concrete slabs 4, and the prefabricated fiber concrete slab 4 is equipped with tongue-and-groove joints 41 and tongue-and-groove joints 41 that engage in the in-situ fiber concrete layer 3 It is a four-sided desktop structure with a wide outside and a narrow inside. The prefabricated ...

Embodiment 2

[0049] Kind of like Figure 5 The fabricated fiber-reinforced concrete composite bridge deck structure shown includes a steel deck layer 1, and the steel deck layer 1 is covered with a fabricated fiber concrete layer 7 (the fabricated fiber concrete layer 7 of this embodiment) It is mainly made of reactive powder concrete pouring), the joint surface between the steel bridge deck layer 1 and the fabricated fiber concrete layer 7 is provided with a shearing member—shear nail 5. The body of the fabricated fiber concrete layer 7 is the cast-in-place fiber concrete layer 3. The cast-in-place fiber concrete layer 3 is embedded with a plurality of prefabricated fiber concrete slabs 4, and the prefabricated fiber concrete slab 4 is surrounded by the in-situ fiber concrete layer 3 The tongue-and-groove joint 41 in the middle, the tongue-and-groove joint 41 is a four-sided table structure with a wide outside and a narrow inside. The prefabricated fiber concrete slab 4 and the cast-in-sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com