WC-Co hard alloy with binding phase enhanced by Ni3Al and preparation method thereof

A cemented carbide and binder phase technology, which is applied in the field of cemented carbide materials and its preparation, can solve the problems of complex phase composition, long preparation cycle, complex process, etc., achieve uniform structure, avoid heat accumulation, and have good dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

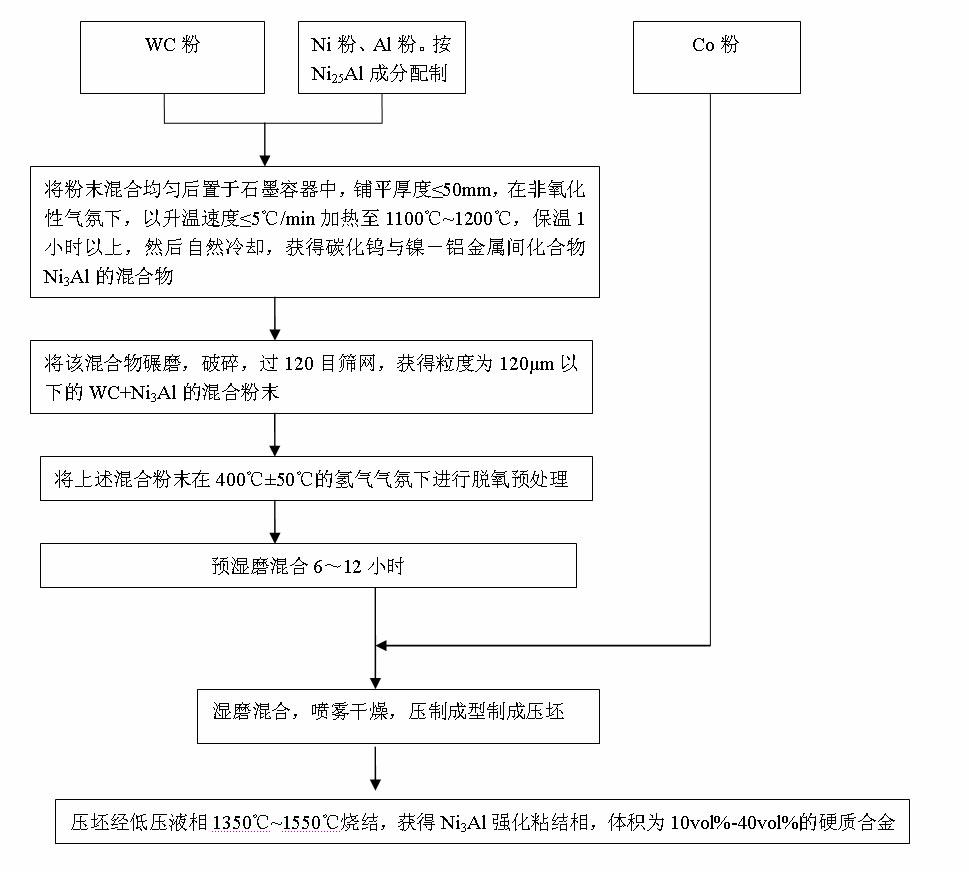

[0016] Embodiment 1: According to figure 1 The flow shown, press Ni 25 The composition ratio of Al, the mass percentage is 2.07% nickel powder and aluminum powder, mixed with the rest of the WC powder evenly; the above mixed powder is placed in a graphite container to pave the thickness of 50 mm, under a non-oxidizing atmosphere, with 5 The heating rate of ℃ / min is heated to 1100 ℃, kept for 7 hours, and then cooled naturally to obtain WC and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 120-mesh sieve to obtain WC+Ni with a particle size of 120 μm or less 3 Mixed powder of Al; the above WC+Ni 3 The mixed powder of Al was subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, the above-mentioned deoxidation pretreated WC+Ni 3 The mixed powder of Al was pre-wet-milled and mixed for 6 hours, then the remaining amount of Co powder (3.57%) was added and then wet-milled for 18 hou...

Embodiment 2

[0017] Embodiment 2: According to figure 1 The flow shown, press Ni 25 The composition ratio of Al, the mass percentage is 2.59% nickel powder and aluminum powder, mixes evenly with the rest WC powder; Place the above-mentioned mixed powder in the graphite container and pave the thickness of 50 mm, under the non-oxidizing atmosphere, with 5 The heating rate of ℃ / min is heated to 1100 ℃, kept for 7 hours, and then cooled naturally to obtain WC and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 120-mesh sieve to obtain WC+Ni with a particle size of 120 μm or less 3 Mixed powder of Al; the above WC+Ni3 The mixed powder of Al was subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, the WC+Ni 3 The mixed powder of Al was pre-wet-milled and mixed for 6 hours, then the remaining amount of Co powder (2.98%) was added and then wet-milled for 27 hours to obtain a wet-milled mixture; th...

Embodiment 3

[0018] Embodiment 3: According to figure 1 The flow shown, press Ni 25 The composition ratio of Al, the mass percentage is 3.08% nickel powder and aluminum powder, and the WC powder of the balance is mixed evenly; The above-mentioned mixed powder is placed in the graphite container and paved with a thickness of 50 mm. The heating rate of ℃ / min is heated to 1100 ℃, kept for 7 hours, and then cooled naturally to obtain WC and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 120-mesh sieve to obtain WC+Ni with a particle size of 120 μm or less 3 Mixed powder of Al; the above WC+Ni 3 The mixed powder of Al was subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, the above-mentioned deoxidation pretreated WC+Ni 3 The mixed powder of Al was pre-wet-milled and mixed for 6 hours, then the remaining amount of Co powder (2.38%) was added and then wet-milled for 36 hours to obtain a wet-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com