Quick spheroidizing annealing technology for GCr15 bearing steel pipe

A bearing steel pipe, spheroidizing annealing technology, applied in the field of bearing steel pipe production, can solve the problems of large carbide dispersion, dense carbide, affecting the dispersion degree of spheroidized structure, etc., and achieve the effect of inhibiting precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

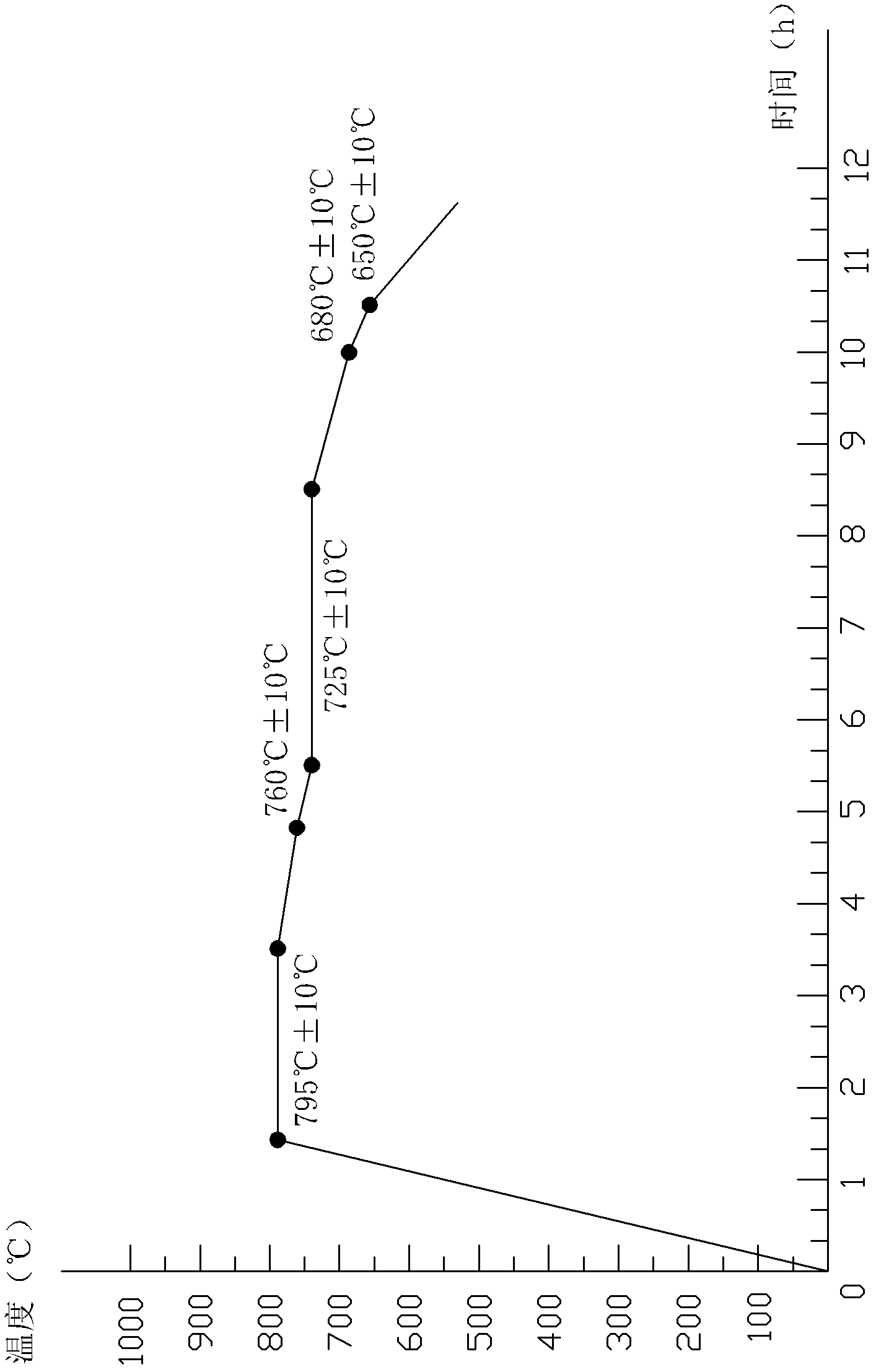

[0026] Such as figure 1 The graph of a kind of embodiment of the present invention shown, GCr15 bearing steel pipe fast spheroidizing annealing process, comprises the following steps:

[0027] 1) After hot-rolling and piercing, the GCr15 bearing steel pipe with a final rolling temperature of 950-1000°C is quickly cooled to 550-650°C through a controlled cooling device, and then air-cooled to room temperature for the first time;

[0028] 2) Spheroidize the GCr15 bearing steel pipe that has been air-cooled for the first time to 795°C±10°C for the first heat preservation;

[0029] 3) Slowly cool the GCr15 bearing steel pipe after the first heat preservation to 760°C±10°C for the first time;

[0030] 4) The GCr15 bearing steel pipe that has been slowly cooled for the first time is quickly cooled to 725°C ± 10°C for the second time;

[0031] 5) Carry out the second heat preservation of the GCr15 bearing steel pipe after the second quick cooling;

[0032] 6) Slowly cool the GCr15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com