Method for synthesizing vinyl benzoate

A vinyl benzoate and vinyl acetate technology, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of environmental pollution, inability to discharge directly, and high processing costs, and reduce production costs , less usage, high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Catalyst preparation method 1

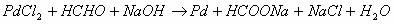

[0022] Activated carbon with a certain surface area and 30% nitric acid solution were put into a three-necked flask and heated to reflux in a water bath at 60°C for 4 hours, then the activated carbon in the solution was filtered out, and the activated carbon filter cake was washed repeatedly with distilled water until neutral, and then dried. Weigh 6.5g of treated activated carbon, 60mL of deionized water and 0.5538g of palladium chloride solution into a three-necked flask, raise the temperature of the reaction solution to 80°C, stir for 6 hours, then cool down to 40°C; add 15mL of 36% HCHO, stir 1h; then NaOH solution (4 mol L -1 ) until the pH of the reaction solution is 8~9, and maintain for 0.5h; the temperature of the reaction solution is then raised to 80°C to promote the reduction reaction, and at the same time, NaOH solution is continuously added to keep the pH constant until the Pd is completely reduced. The supported activated ...

Embodiment 1

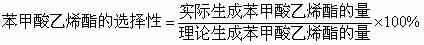

[0028] Add 5.5g of benzoic acid, 35.0g of vinyl acetate, and 1.2243g of catalyst A into a 250mL four-neck flask, stir while heating to 80°C, and reflux for 10 hours. The selectivity of vinyl benzoate is measured to be 95.78%. .

Embodiment 2

[0030] Add 5.5g of benzoic acid, 35.0g of vinyl acetate, and 1.4182g of catalyst A into a 250mL four-neck flask, stir while heating to 80°C, and reflux for 10 hours. The selectivity of vinyl benzoate is measured to be 97.08%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com