Method for preparing activated carbon by using flax straws

A technology for preparing activated carbon and hemp stalks, which is applied in the field of powdered activated carbon preparation to achieve the effects of reducing production costs, protecting the environment, and saving production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

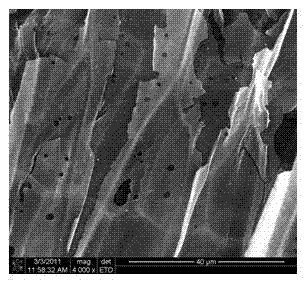

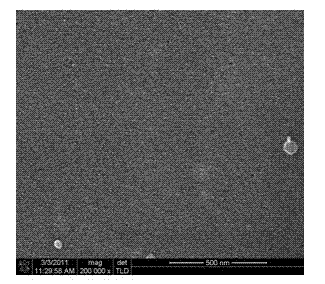

Image

Examples

Embodiment 1

[0020] The kenaf or jute is peeled, crushed, passed through a 40-mesh sieve, and dried at 105°C for 12 hours to obtain a pretreated dry material weighing 20g, and the mass ratio of the potassium permanganate solution with a mass concentration of 0.2% is 2: 100 and mix evenly, impregnate at room temperature for 12 hours, then dry at 105°C for 24 hours to obtain a mixture. Then put the mixture in a muffle furnace, raise the temperature to 800°C at a rate of 5°C / min, keep it warm for 120 minutes, the temperature difference during the heat preservation period is less than ±15°C, and cool naturally to room temperature to obtain a carbonized activated sample. Finally, the carbonized activated sample was cooked with 5% HCl solution at 70°C for 30 minutes, then repeatedly washed with deionized water until the pH was 6~7, dried at 105°C for 24 hours, finally ground, and passed through a 200-mesh sieve to obtain a powder Activated carbon finished product.

Embodiment 2

[0022] The kenaf or jute is peeled, crushed, passed through a 40-mesh sieve, and dried at 120°C for 12 hours to obtain a pretreated absolute dry material weighing 20g, and the mass ratio of the potassium permanganate solution with a mass concentration of 0.6% is 1: 100 and mix evenly, impregnate at room temperature for 8 hours, then dry at 120°C for 12 hours to obtain a mixture. Then put the mixture in a muffle furnace, raise the temperature to 900°C at a rate of 10°C / min, hold it for 60 minutes, and keep the temperature difference less than ±15°C during the hold, and cool it down to room temperature naturally to obtain a carbonized activated sample. Finally, the carbonized activated sample was digested with 10% HCl solution at 90°C for 60 minutes, then repeatedly washed with deionized water until the pH was 6~7, dried at 120°C for 12 hours, finally ground, and passed through a 200-mesh sieve to obtain a powder Activated carbon finished product.

Embodiment 3

[0024] The kenaf or jute is peeled, crushed, passed through a 40-mesh sieve, and dried at 110°C for 12 hours to obtain a pretreated dry material weighing 20g, and the mass ratio of the potassium permanganate solution with a mass concentration of 1.0% is 6: 100, mix evenly, soak at room temperature for 4 hours, then dry at 108°C for 18 hours to obtain a mixture. Then put the mixture in a muffle furnace, raise the temperature to 700°C at a rate of 8°C / min, hold it for 180 minutes, and keep the temperature difference less than ±15°C during the hold, and cool it down to room temperature naturally to obtain a carbonized activated sample. Finally, the carbonized activated sample was cooked with 8% HCl solution at 80°C for 45min, then repeatedly washed with deionized water until the pH was 6~7, dried at 108°C for 20h, finally ground, and passed through a 200-mesh sieve to obtain a powder Activated carbon finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com