Method for preparing nutritious flavoring by using shellfishes and by-products of shellfishes

A condiment and shellfish technology, applied in food preparation, application, food science, etc., can solve the problems of destroying the natural flavor of seafood condiments, complex and expensive equipment, and complicated processes, so as to protect the marine ecological environment, taste good, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Shellfish Nutritious Seasoning Prepared by Double Enzyme Hydrolysis and Yeast Fermentation

[0048] Enzyme type: compound protease (enzyme activity 1.5AU / g) + compound flavor protease (enzyme activity 1000AU / g) (NovoNordisk, Denmark)

[0049] Ester-producing yeast species: Ester-producing yeast 1274+1202 strain (Jinan Jiuyi Bioengineering Co., Ltd.).

[0050] Measurement indicators: amino acid nitrogen (FAN) content, total ester content, sensory evaluation.

[0051] Step a: take oysters as raw materials, wash and shell them, and homogenate shellfish (JM-FB colloid mill, rotating speed 2900r / min, emulsification fineness 50μm).

[0052] Step b: Enzymolyze the homogenized shellfish at 50°C for 6 hours, add 0.4% enzyme (calculated as fresh shellfish), and compound enzymes are compound protease + compound flavor protease. Protease (Protamex) 1.1l×10 5 U / g, compound flavor protease (Flavorzyme) 3.0×10 4 U / g, both were purchased from NovoNordisk Company in Denma...

Embodiment 2

[0060] Embodiment 2, utilize mussel poached liquid concentrated juice to make mussel nutritious seasoning sauce process

[0061] Enzyme type: Bacillus subtilis neutral protease (enzyme activity 10 5 U / g, purchased from Wuxi Geneng Science and Biological Co., Ltd.) + papain (enzyme activity 6 × 10 5 U / g, purchased from Guangzhou Yuantian Enzyme Preparation Factory).

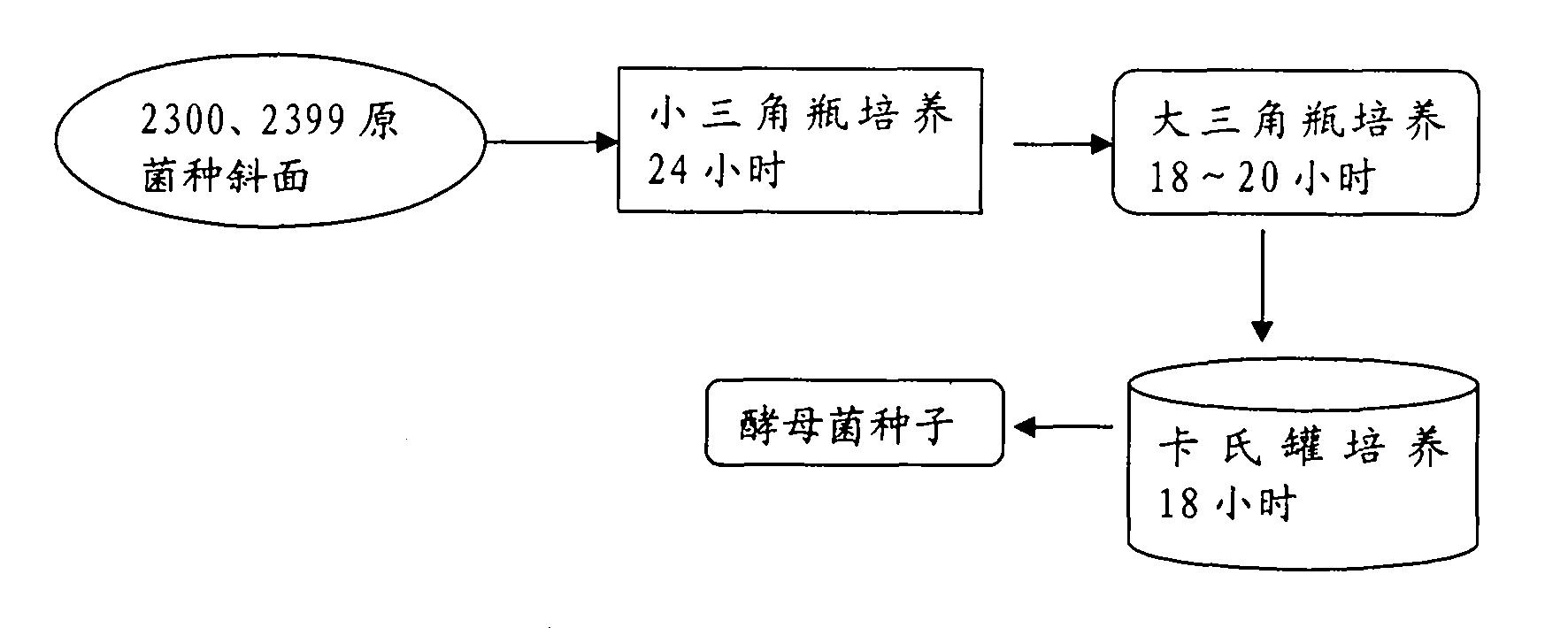

[0062] Yeast species: Saccharomyces cerevisiae 2399, and ester-producing yeast 2300 (both were purchased from Shandong Liangshan Liangyou Bioengineering Co., Ltd.).

[0063] Step a: Enzymolysis of ingredients. Mussel concentrate 1000ml, soybean protein powder 2g, Bacillus subtilis neutral protease 5g, papain 5g.

[0064] Step b: enzymatic hydrolysis. Stir the above substances evenly, and use the natural pH value (pH=7) to perform enzymatic hydrolysis at 50° C. for 3 hours.

[0065] Step c: dilution and batching. Dilute the above enzymolysis solution with drinking water 1:1 to obtain a diluted solution, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com