Composite pumpkin pulp beverage and production method thereof

A technology for pumpkin pulp and pumpkin, applied in the application, food preparation, food science and other directions, can solve the problems of easy stratification, precipitation and uncoordinated flavor of fruit and vegetable compound juice, unstable pulp beverage, etc. Adverse effects of nutrition, solution stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

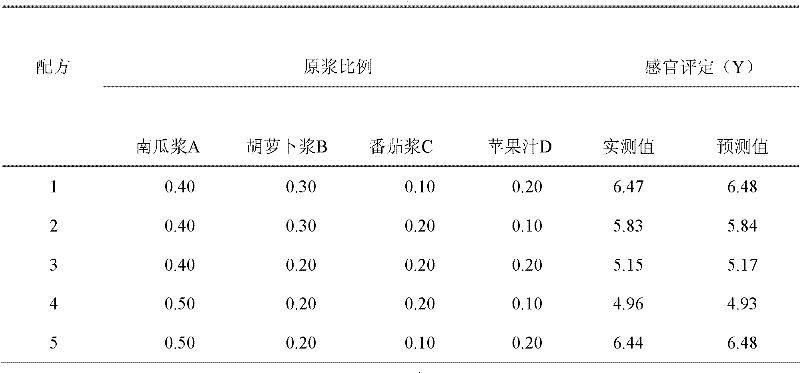

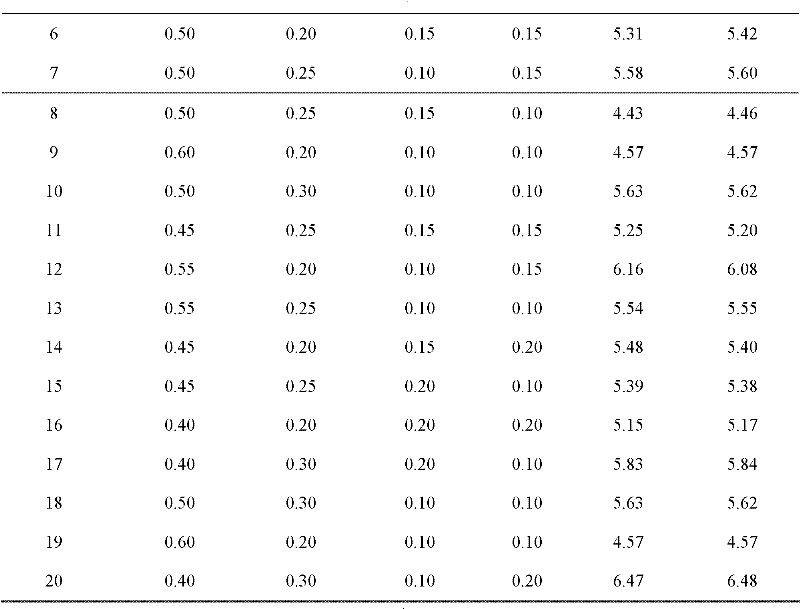

Method used

Image

Examples

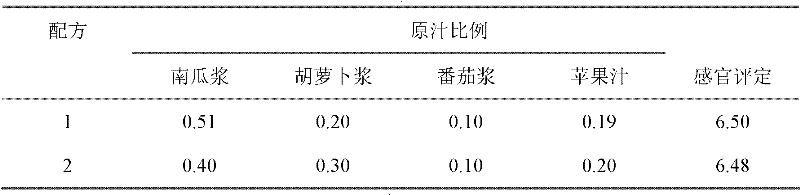

Embodiment 1

[0055] (1) Select fresh and ripe pumpkins, carrots and tomatoes as raw materials, wash, slightly peel, segment, and remove seeds, and carry out inter-process color protection of pumpkins and carrots in clear water or 0.1% to 0.3% citric acid solution ( Time ≤ 3h), wash and drain in a pressure cooker (pressure ≥ 2kg / cm 2 ) cook until cooked, add 1 to 2 times the weight of raw materials for beating, and pass through a colloid mill; tomato pulp is made into tomato puree, adjust its pH value to 3.5 to 4.0 with citric acid, keep warm at 35 to 45°C for 1 to 2 hours, and pass through the colloid Grinding; concentrated apple juice reduced to 100% apple juice.

[0056] (2) Compound pumpkin pulp, carrot pulp, tomato pulp and apple juice according to 51% of pumpkin pulp, 20% of carrot pulp, 10% of tomato pulp and 19% of apple juice, mix well, add pure water to make the total The content of raw material slurry accounts for 28% of the total volume.

[0057] (3) Add fructose syrup 6%, fru...

Embodiment 2

[0060] (1) Select quick-frozen pumpkins and quick-frozen carrots, grind them directly, add 60°C pure water twice the weight of the raw materials to thaw until the temperature rises to 10°C, add concentrated tomato pulp and concentrated apple juice directly, the original pulp accounts for 30% of the total weight .

[0061] (2) Compound pumpkin puree, carrot puree, tomato puree and apple juice in ratios of 0.50, 0.15, 0.15 and 0.20, and mix well.

[0062] (3) Add 7.5% sucrose, 1% fructooligosaccharide, 0.5% isomaltulose, acid-resistant CMC: 0.045%, gellan gum: 0.01%, xanthan gum 0.04%, Vc: 25mg / kg, with citric acid Mix with malic acid in a ratio of 1:1 to form a 50% solution to adjust the pH value of the composite slurry to 4.0, and then homogenize twice at 30Mpa to obtain a uniform and stable pumpkin composite slurry beverage.

[0063] (4) Bottle the homogenized pumpkin composite pulp beverage or put it in a can (250ml) and exhaust it in a water bath at 85-90°C for 10 minutes,...

Embodiment 3

[0065] (1) Select fresh and ripe pumpkins, carrots and tomatoes as raw materials, wash, slightly peel, cut, and remove seeds, respectively add 1 to 2 times the weight of raw materials for beating, and adjust the pH value of pumpkin pulp with citric acid. 5.5 to 6.5, heat at 30 to 45°C for 1 to 2 hours, then pass through a colloid mill for later use. Use citric acid to adjust the pH value of the carrot pulp to 4.5-5.0, keep it warm at 35-45°C for 1-2 hours, and pass it through a colloid mill for later use. For tomato puree, adjust its pH value to 3.5-4.0 with citric acid, keep it warm at 35-45°C for 1-2 hours, pass through a colloid mill for later use; it can also be reduced to tomato puree by adding water to the concentrated tomato puree, and pass through a colloid mill for later use.

[0066] (2) Compound pumpkin pulp, carrot pulp, tomato pulp and apple juice according to 60% of pumpkin pulp, 15% of carrot pulp, 10% of tomato pulp and 15% of apple juice, mix well, add pure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com