Method for producing pectinase by fermentation of recombinant Escherichia coli

A technology for recombining Escherichia coli and pectinase, applied in the field of fermentation engineering, can solve the problems affecting the synthesis of target proteins, cell physiology and metabolic changes, etc., and achieves a simple and easy method, improves secretion and expression efficiency, and improves yield and production intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Strain: E.coli BL21DE3(pET-20b(+)PGL), expressed by extracellular secretion.

[0037] Medium:

[0038] 1) Seed medium (LB): Yeast powder 5g L -1 , Tryptone 6-14g L-1, NaCl 6-14g L-1, Ampicillin 1mM, pH 7.0

[0039] 2) Fermentation medium (MTB): glycerin 6-14g L-1, yeast powder 24g L -1 , peptone 12g L -1 , KH 2 PO 4 17mM,K 2 HPO 4 72mM, ampicillin 0.1mM

[0040] 3) Solid plate medium: LB medium, 1.5% agar

[0041] 4) Glycerol feeding medium: glycerol 500g L -1 , yeast powder 50g L -1 , peptone 50g L -1

[0042] Training method:

[0043] 1) Seed culture: Inoculate the preserved strains into a 250mL Erlenmeyer flask containing 25mL LB medium, and cultivate for 8 hours at a rotary shaker with a rotation speed of 200r / min and a culture temperature of 37°C.

[0044] 2) Fermentation culture: Inoculate the bacterial liquid in LB into a fully automatic 3L fermenter (BioFlo 110, New Brunswick Scientific Co.) with a 5% inoculum amount.

[0045] MTB medium (containi...

Embodiment 2

[0053] The parameters of the fermentation process are slightly different, and all the other materials and methods are the same as in Example 1, using MTB medium (containing 100 μg mL -1 Ampicillin) is the fermentation medium, and the whole fermentation process can be divided into three stages:

[0054] 1) The initial glycerol concentration is 10g L-1, and the culture temperature is 37°C. When the DO rebound glycerol is exhausted, the second stage begins;

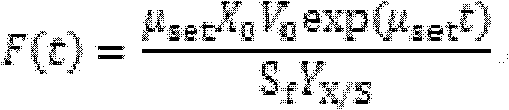

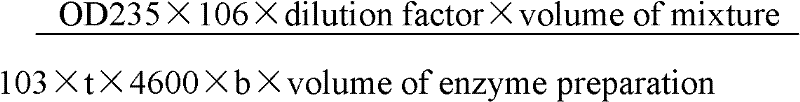

[0055] 2) Carry out exponential feed glycerol medium according to the following formula, and the specific growth rate is 0.2h -1

[0056] F ( t ) = μ set X 0 V 0 exp ( μ set t ...

Embodiment 3

[0061] The parameters of the fermentation process are slightly different, and all the other materials and methods are the same as in Example 1, using MTB medium (containing 100 μg mL -1 Ampicillin) is the fermentation medium, and the whole fermentation process can be divided into three stages:

[0062] 1) The initial glycerol concentration is 14g L-1, and the culture temperature is 37°C. When the DO rebound glycerol is exhausted, the second stage begins;

[0063] 2) Carry out exponential feed glycerol medium according to the following formula, and the specific growth rate is 0.23h -1

[0064] F ( t ) = μ set X 0 V 0 exp ( μ set t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com