Method for preparation of sulfuric acid and combined production of fine flour iron through calcination of coal-derived pyrite in presence of oxygen-rich air

A technology of oxygen-enriched air and pyrite, which is applied in the field of resource utilization of coal-containing pyrite, can solve the problems of reduced heat recovery efficiency, waste of resources, and reduction of sulfur dioxide concentration in furnace gas, so as to reduce the content of sulfur dioxide and nitrogen oxides , heat recovery efficiency is improved, and the effect of slag and dust residual sulfur is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the embodiments of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

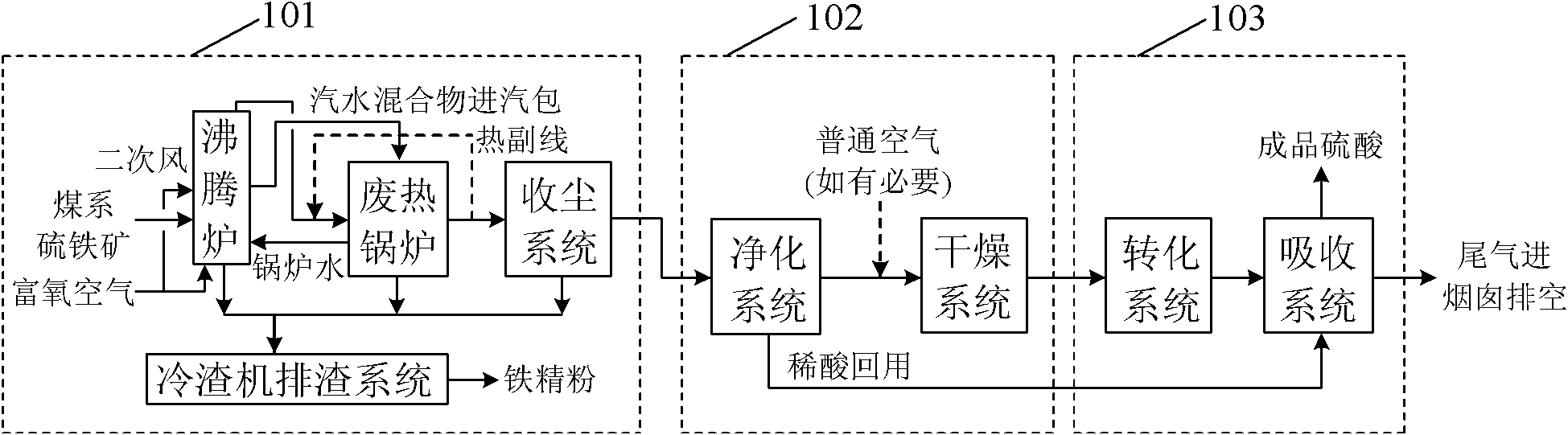

[0027] figure 1 It is the process flow chart of the method embodiment of the co-production of sulfuric acid co-production iron fine powder for coal-measure pyrite roasting of the present invention, as figure 1 As shown, the method includes:

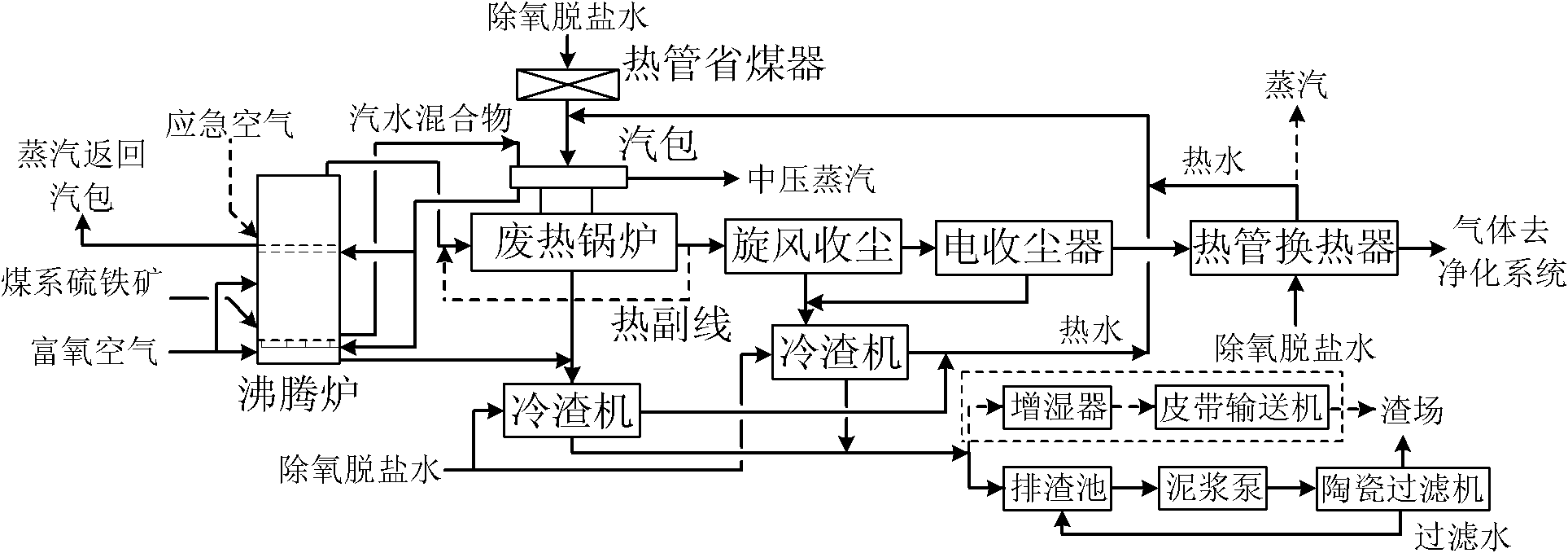

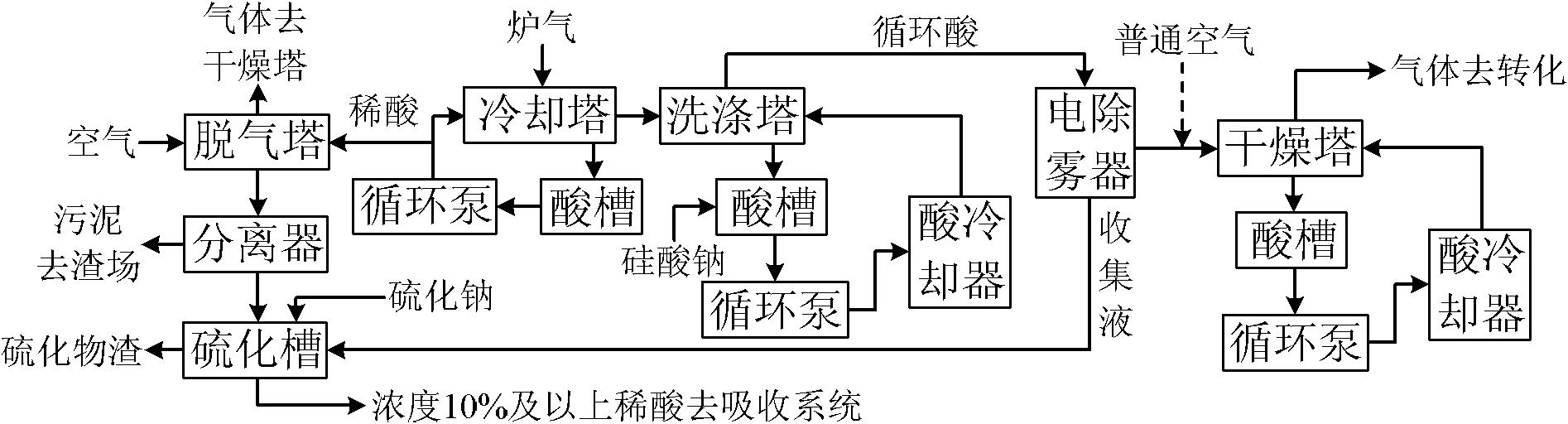

[0028] Step 101, feed coal-based pyrite and oxygen-enriched air into the fluidized fluidized furnace for combustion, and discharge high-temperature furnace gas after combustion, and the furnace gas passes through the subsequent water pipe waste heat boiler, cyclone dust collector, electric dust collector and heat pipe boiler (or heat pipe province Coal burner) is sent to the follow-up purification system after cooling down and dedusting. The heat released by the combustion of the coal-based pyrite and oxygen-enriched air is removed from the fluidized furnace in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com