High-temperature-resistant electric wire and preparation process thereof

A high-temperature-resistant wire technology, which is applied in the field of high-temperature-resistant wires and its preparation technology, can solve the problems that the long-term working temperature can only reach 200°C and cannot meet the requirements of higher temperature working environments, and achieve improved anti-interference performance and light weight , the effect of small outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

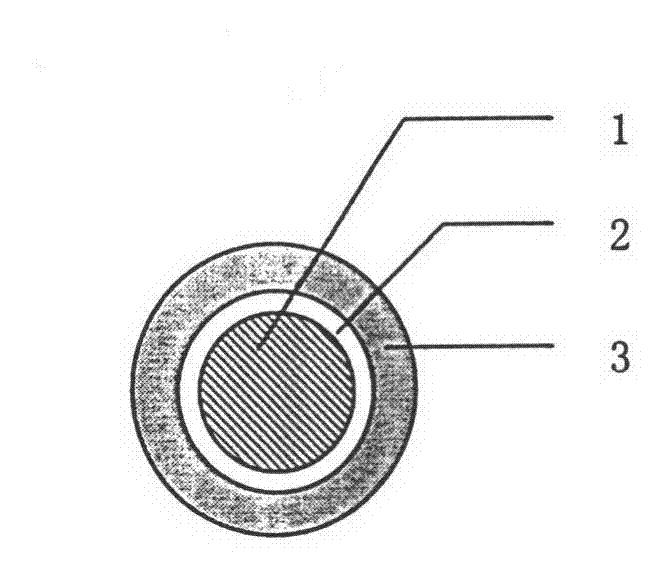

[0020] Control attached figure 1 , the structure of which is a regular stranded nickel-plated round copper wire conductor 1. The periphery of the conductor 1 is an inner insulating layer 2 wrapped with polyimide composite tape (PTFE / PI / PTFE). The outer periphery of the inner insulating layer is made of a braiding machine Braided high temperature resistant alkali-free glass fiber outer insulation layer 3.

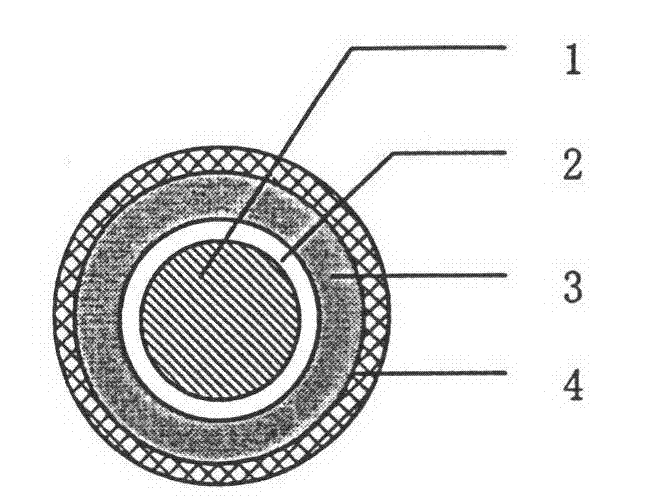

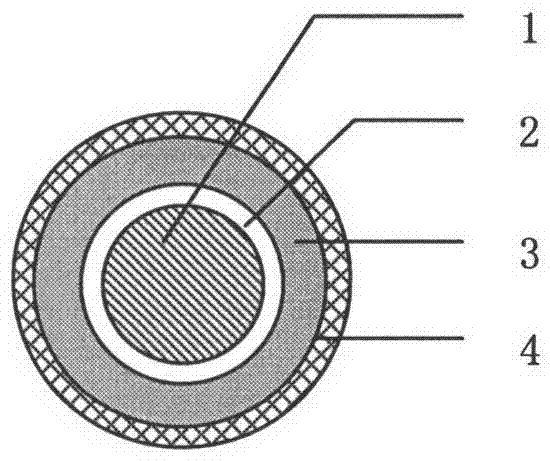

[0021] Control attached figure 2 , the structure of which is a regular stranded nickel-plated round copper wire conductor 1. The periphery of the conductor 1 is an inner insulating layer 2 wrapped with polyimide composite tape (PTFE / PI / PTFE). The outer periphery of the inner insulating layer is made of a braiding machine Braided high temperature resistant alkali-free glass fiber outer insulation layer 3.

[0022] The periphery of the high-temperature-resistant alkali-free glass fiber outer insulation layer 3 woven by a braiding machine is a nickel-plated round copper wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com