Thick plate submerged arc welding technology for low-temperature maritime engineering

A welding process and submerged arc welding technology, which is applied in the field of submerged arc welding of thick plates for low-temperature marine engineering, can solve the problems of increased labor intensity, long research and development cycle, and high cost, and achieve excellent overall joint performance and good impact toughness reserve. and the effect of safety and wealth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of submerged arc welding process of F550 submerged arc welding of thick plate for low temperature marine engineering, the process comprises the following steps:

[0021] Thick plate F550 for low temperature marine engineering, its chemical composition and weight percentage are: C: 0.08%, Si: 0.28%, Mn: 1.53%, P: 0.006%, S: 0.001%, Als: 0.006%, Nb: 0.024 %, Ti: 0.010%, Zr: 0.006%, Cr+Mo+Ni+Cu=2.0%, steel carbon equivalent Ceq=0.55%, and the balance is Fe and trace impurities. Its thickness is 60mm.

[0022] The welding material is Spoolarc ENi4, its composition is: 0.165%C, 0.84%Mn, 0.19%Si, 0.003%S, 0.009%P, 0.009%Cu, 0.1%Cr, 0.15%Mo, 1.73%Ni, 0.004Al, flux Grade OK FLUX 10.62. Wire diameter: 4mm.

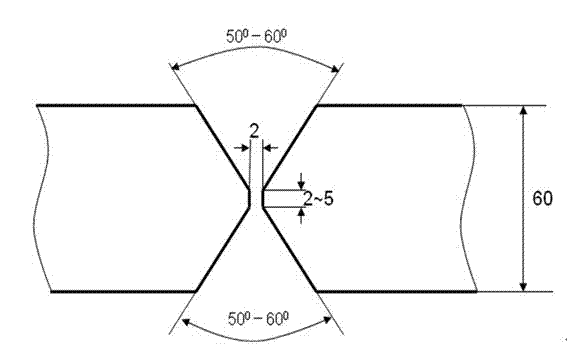

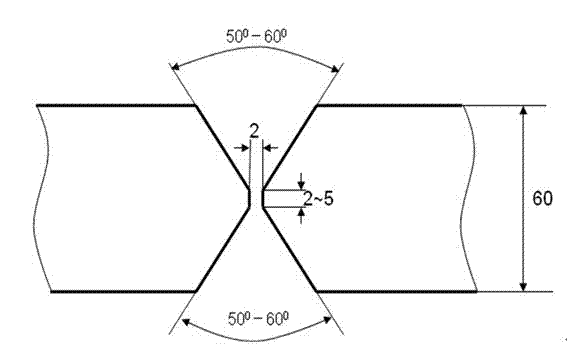

[0023] Using submerged arc welding method. The groove adopts a symmetrical double-sided X-shaped groove, the groove angle is 50-60°, and the groove gap is 2-5mm. When the ambient temperature is not lower than 10°C, the F550 low-temperature marine thick plate shoul...

Embodiment 2

[0026] Another F550 submerged arc welding process for thick plates used in low-temperature marine engineering, the process includes the following steps:

[0027] Thick plate F550 for low temperature marine engineering, its chemical composition and weight percentage are: C: 0.08%, Si: 0.28%, Mn: 1.53%, P: 0.006%, S: 0.001%, Als: 0.006%, Nb: 0.024 %, Ti: 0.010%, Zr: 0.006%, Cr+Mo+Ni+Cu=2.0%, steel carbon equivalent Ceq=0.55%, and the balance is Fe and trace impurities. Its thickness is 60mm.

[0028] The welding material is Spoolarc ENi4, its composition is: 0.165%C, 0.84%Mn, 0.19%Si, 0.003%S, 0.009%P, 0.009%Cu, 0.1%Cr, 0.15%Mo, 1.73%Ni, 0.004Al, flux Grade OK FLUX 10.62. Wire diameter: 4mm.

[0029] Using submerged arc welding method. The groove adopts a symmetrical double-sided X-shaped groove, the groove angle is 50-60°, and the groove gap is 2-5mm. When the ambient temperature is not lower than 10°C, the F550 low-temperature marine thick plate should be preheated at 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com