Biomimetic polymer, and preparation method and application thereof

A technology of copolymer and imitating cell outer layer membrane, which is applied in the field of (meth)acrylate copolymer, biomimetic copolymer and its preparation, can solve the problems of unstable coating and unsatisfactory material modification effect, and achieves the The effect of easy storage, excellent stability and biocompatibility, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

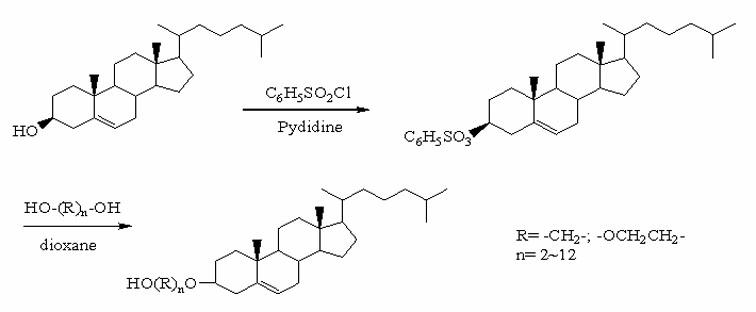

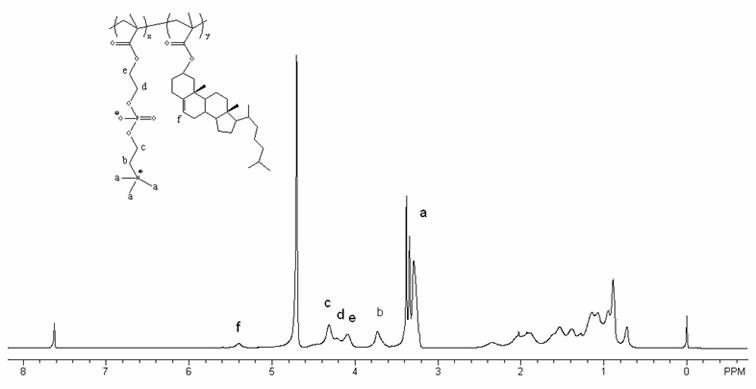

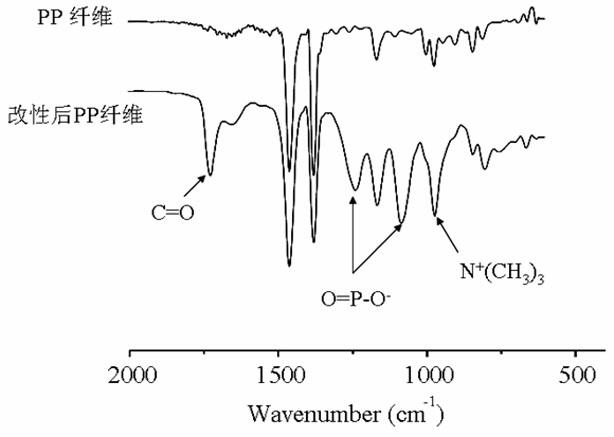

[0036] Embodiment 1 The preparation of the copolymer PMC64 containing phosphorylcholine group and cholesterol hydrophobic side group

[0037] in dry N 2 Under protection, add 10mL of a dry mixture of ethanol and tetrahydrofuran (1 / 1, v / v) to a 100mL three-necked flask, add a condenser tube and a calcium chloride drying tube, heat the oil bath to 70°C, and the molar percentage is 60 :40 Weigh MPC and cholesterol methacrylate (CholMA), dissolve them in 30 mL ethanol and tetrahydrofuran respectively, and mix well. After the initiator AIBN of 2.0wt% (accounting for the percentage of total monomer mass) is dissolved with 6mL anhydrous tetrahydrofuran, wherein 2mL is added in the three-necked bottle, 3mL is added in the monomer mixture, after the temperature stabilizes, use it under electromagnetic stirring The constant pressure dropping funnel drips the mixture of monomer and initiator into the three-neck bottle, and controls the dropping speed. After 3-4 hours, stop the N 2 , s...

Embodiment 2

[0039] Weigh methacryloyloxytetraethylene glycol-based phosphorylcholine and 10-cholesteryloxydecyl methacrylate at a molar percentage of 30:70, dissolve them in 30 mL of isopropanol and 50 mL of tetrahydrofuran, and mix well. After the initiator AIBN of 0.5wt% (accounting for the percentage of total monomer mass) is dissolved with 6mL anhydrous tetrahydrofuran, wherein 1.5mL is added in the three-necked bottle, 3.5mL is added in the monomer mixture, after the temperature stabilizes, under electromagnetic stirring Use a constant pressure dropping funnel to drop the mixture of monomer and initiator into the three-necked bottle, control the dropping speed, finish dropping in 3-4 hours, stop the N after dropping 2 , sealed, and after the system continued to react for 4 hours, the remaining 1 mL of AIBN in anhydrous tetrahydrofuran solution was added, and the reaction was stopped after 24 hours. Concentrate the reaction liquid to 15-20mL, use dialysis method (the molecular weight ...

Embodiment 3

[0041] Take MPC and cholesteryloxyethylene glycol methacrylate by molar percentage 80:20, mix with 60mL isopropanol and 30 THF respectively after dissolving, the initiator AIBN of 5.0wt% (accounting for the percentage of total monomer mass) After dissolving with 6mL of anhydrous tetrahydrofuran, add 0.5mL into the three-neck flask, and add 4mL into the monomer mixture. After the temperature is stable, use a constant pressure dropping funnel to drop the monomer into the three-neck flask under electromagnetic stirring and trigger The mixed solution of the agent, control the dropping speed, finish dropping in 3-4h, stop N after dropping 2 , sealed, and the system continued to react for 4 hours, and then added 1.5 mL of AIBN in anhydrous tetrahydrofuran solution, and the reaction was stopped after 24 hours. Concentrate the reaction liquid to 15-20mL, use dialysis method (the molecular weight cut-off of the dialysis bag is 6000-7000D) to purify the crude product, freeze-dry and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com