Preparation of ferrocenyl benzoxazine-containing monomer or precursor and heat reactive resin thereof

A ferrocene-based benzene and precursor technology, applied in metallocene, organic chemistry, chemical instruments and methods, etc., can solve problems such as reducing the temperature resistance of benzoxazine resin, achieve improved performance, simple preparation method, The effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In a 100ml round-bottom flask equipped with a condenser tube, add monoaminoferrocene (0.01mol, 2.01g), phenol (0.011mol, 1.034g), paraformaldehyde (0.022mol, 0.66g), and then add 50.12 chloroform ml, electromagnetic stirring, heating at 60 °C for 24 h, cooling to room temperature, washing the chloroform solution containing the product once with 0.1 mol / L NaOH aqueous solution, and then washing with pure water until neutral. The solvent was removed by rotary evaporation under reduced pressure and dried to obtain a ferrocene-containing benzoxazine monomer. The ferrocene-based benzoxazine monomer is cured under a temperature-programmed curing process to obtain a ferrocene-based benzoxazine resin. The specific curing process is: 60 ℃ 1h + 100 ℃ 1h + 140 ℃ 1h + 200 ℃ 1h + 240℃ 1h.

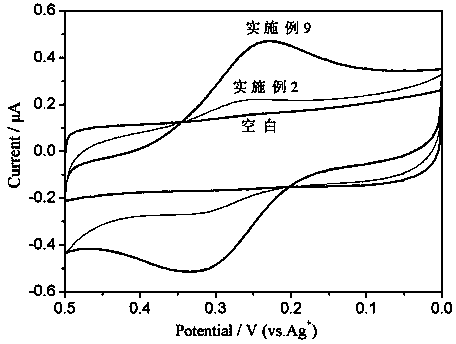

Embodiment 2

[0050] In a 100ml round-bottomed flask equipped with a condenser tube, add monoaminomethyl ferrocene (0.11mol, 23.65g), p-cresol (0.10mol, 10.80g), paraformaldehyde (0.22mol, 6.6g), Then add 55.55 ml of chloroform, stir electromagnetically, heat at 110 °C for 12 h, cool down to room temperature, use 5 mol / L Na 2 CO 3 The chloroform solution containing the product was washed once with an aqueous solution, and then washed with pure water until neutral. The solvent was removed by rotary evaporation under reduced pressure and dried to obtain a ferrocene-containing benzoxazine monomer. The ferrocene-based benzoxazine monomer is cured under a temperature-programmed curing process to obtain a ferrocene-based benzoxazine resin. The specific curing process is: 60 ℃ 1h + 80 ℃ 1h + 120 ℃ 1h + 170 ℃ 1h + 220℃ 1h.

Embodiment 3

[0052] In a 100ml round-bottomed flask equipped with a condenser, add monoaminoethylferrocene (0.105mol, 24.045g), m-cresol (0.105mol, 11.34g), paraformaldehyde (0.21mol, 6.3g), Then add 28.20 ml of chloroform, stir electromagnetically, heat at 90 °C for 3 h, cool down to room temperature, use 3 mol / L NaHCO 3 The chloroform solution containing the product was washed once with an aqueous solution, and then washed with pure water until neutral. The solvent was removed by rotary evaporation under reduced pressure and dried to obtain a ferrocene-containing benzoxazine monomer. The ferrocene-based benzoxazine monomer is cured under a temperature-programmed curing process to obtain a ferrocene-based benzoxazine resin. The specific curing process is: 60 ℃ 1h + 90 ℃ 1h + 130 ℃ 1h + 180 ℃ 1h + 230℃ 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com