Production process for nanometer barium sulfate

A nano-barium sulfate and production method technology, applied in the direction of nanotechnology, calcium/strontium/barium sulfate, etc., can solve the problems of large reagent consumption, large saline wastewater, high production cost, etc., and achieve convenient operation and simple production process , Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

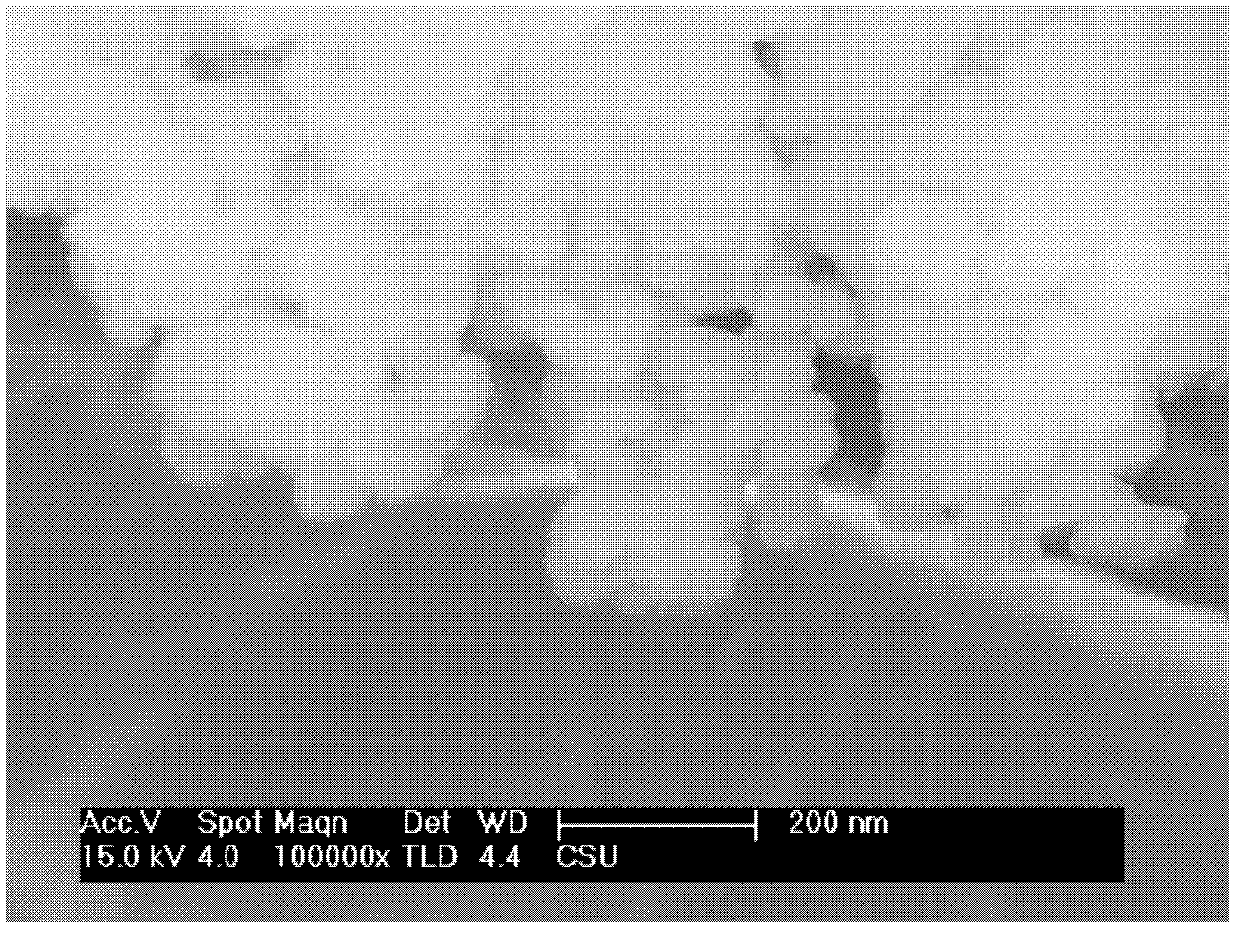

Image

Examples

Embodiment 1

[0034] 1000mL concentration is H 2 SO 410wt% sulfuric acid solution, add 10g sodium nitrate and 5g sodium chlorate as catalyst, add 100g sodium sulfate and 50g potassium sulfate as buffer, stir and add 200g barium carbonate, 25 ℃ of catalytic conversion 8 hours, filter to get barium sulfate filter cake and After transformation, the barium sulfate filter cake was added with water at a solid-liquid ratio of 1: 3g / ml, stirred and washed at 30°C for 2 hours and filtered, then rinsed with absolute ethanol with 1 times the volume of the filter cake, and dried at 95°C for 3 hours to obtain a purity of 98.8% barium sulfate products with a particle size of 30-60nm.

Embodiment 2

[0036] Add 50ml vitriol oil (98%) in the liquid after transformation that embodiment 1 obtains and make reactant, add 6g sodium chloride and make catalyzer, stir and add 190g barium carbonate, 45 ℃ of catalytic transformations 6 hours, filter to get barium sulfate filter cake and Transformation liquid, barium sulfate filter cake after drying, then according to the solid-liquid ratio 1: 3g / ml add water 60 ℃ stirring and washing for 1 hour and filter, filter cake is added water and adjusted to a slurry with a solid content of 50%, spray drying at 180 ℃ to obtain a purity of 99.6% barium sulfate product with a particle size of 40-85nm.

Embodiment 3

[0038] Add 120ml vitriol oil (98%) in the liquid after transformation that embodiment 2 obtains and make reactant, add 1g sodium chlorate and 5g sodium nitrate and make catalyst, 20g ammonium sulfate make buffering agent, stir and add 400g barium carbonate, 65 ℃ of catalysis After transformation for 4 hours, filter the barium sulfate filter cake and the liquid after transformation. Add water to the barium sulfate filter cake at a solid-to-liquid ratio of 1:5g / ml, stir and wash at 85°C for 0.5 hours and filter, then rinse with absolute ethanol that is 1.5 times the volume of the filter cake Finally, dry at 105° C. for 2 hours to obtain a barium sulfate product with a purity of 99.1% and a particle size of 45-90 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com