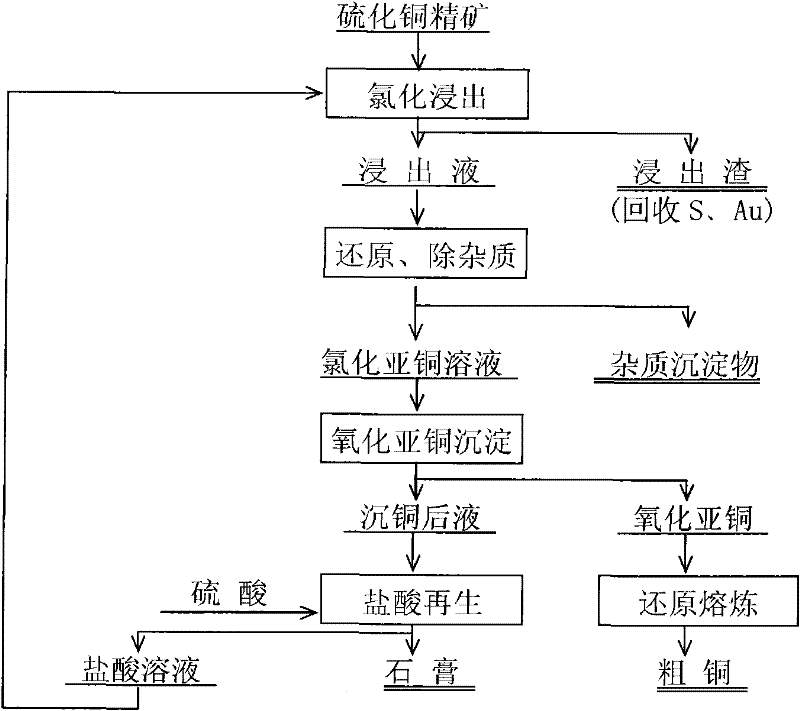

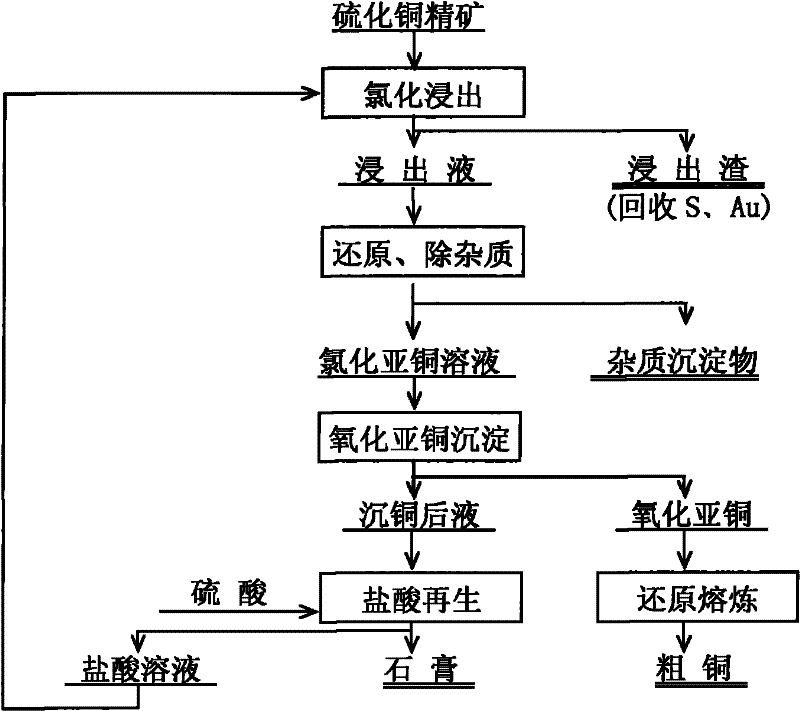

Method for producing blister copper by reduction smelting of cuprous oxide converted from cuprous chloride

A technology of cuprous oxide and cuprous chloride, which is applied in the field of copper smelting, can solve problems such as complex process flow, troublesome process, and complicated technology, and achieve the effects of high copper recovery rate, reduced production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The copper sulfide concentrate is chlorinated and leached, and sulfur and gold are recovered from the leached slag; after the leaching solution is reduced, purified, and impurities removed, a cuprous chloride solution is obtained, and limestone is added to the cuprous chloride solution to precipitate cuprous oxide. The precipitated cuprous oxide is subjected to reduction smelting. The technical conditions for cuprous oxide precipitation are: the concentration of monovalent copper ions is 20g / L, the ratio of the amount of limestone added to the theoretical amount is 1, the precipitation temperature is 40°C, the reaction time is 60min, and the pH value at the end of the reaction is 7. After the reaction is completed, the solid-liquid separation is carried out, and the solid cuprous oxide is reduced and smelted to obtain crude copper; the filtrate is added with sulfuric acid to regenerate the hydrochloric acid, and at the same time the by-product gypsum is produced, and the...

Embodiment 2

[0043]The copper sulfide concentrate is chlorinated and leached, and sulfur and gold are recovered from the leached slag; after the leaching solution is reduced, purified, and impurities removed, a cuprous chloride solution is obtained, and limestone is added to the cuprous chloride solution to precipitate cuprous oxide. The precipitated cuprous oxide is subjected to reduction smelting. The technical conditions for cuprous oxide precipitation are: the concentration of monovalent copper ions is 45g / L, the ratio of the amount of limestone added to the theoretical amount is 1.05, the precipitation temperature is 70°C, the reaction time is 60min, and the pH value at the end of the reaction is 7.5. After the reaction is completed, the solid-liquid separation is carried out, and the solid cuprous oxide is reduced and smelted to obtain crude copper; the filtrate is added with sulfuric acid to regenerate the hydrochloric acid, and at the same time the by-product gypsum is produced, and...

Embodiment 3

[0051] The copper sulfide concentrate is chlorinated and leached, and sulfur and gold are recovered from the leached slag; after the leaching solution is reduced, purified, and impurities removed, a cuprous chloride solution is obtained, and limestone is added to the cuprous chloride solution to precipitate cuprous oxide. The precipitated cuprous oxide is subjected to reduction smelting. The technical conditions for cuprous oxide precipitation are: the concentration of monovalent copper ions is 65g / L, the ratio of the amount of limestone added to the theoretical amount is 1.1, the precipitation temperature is 70°C, the reaction time is 120min, and the pH value at the end of the reaction is 8.0. After the reaction is completed, the solid-liquid separation is carried out, and the solid cuprous oxide is reduced and smelted to obtain crude copper; the filtrate is added with sulfuric acid to regenerate the hydrochloric acid, and at the same time the by-product gypsum is produced, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com