Combined hydrogenation method for producing catalytic raw material and high-quality diesel oil

A combined method and diesel technology, which can be used in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as technical and economic constraints, reduce equipment investment and operating costs, achieve high selectivity and high activity, and achieve high application efficiency. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

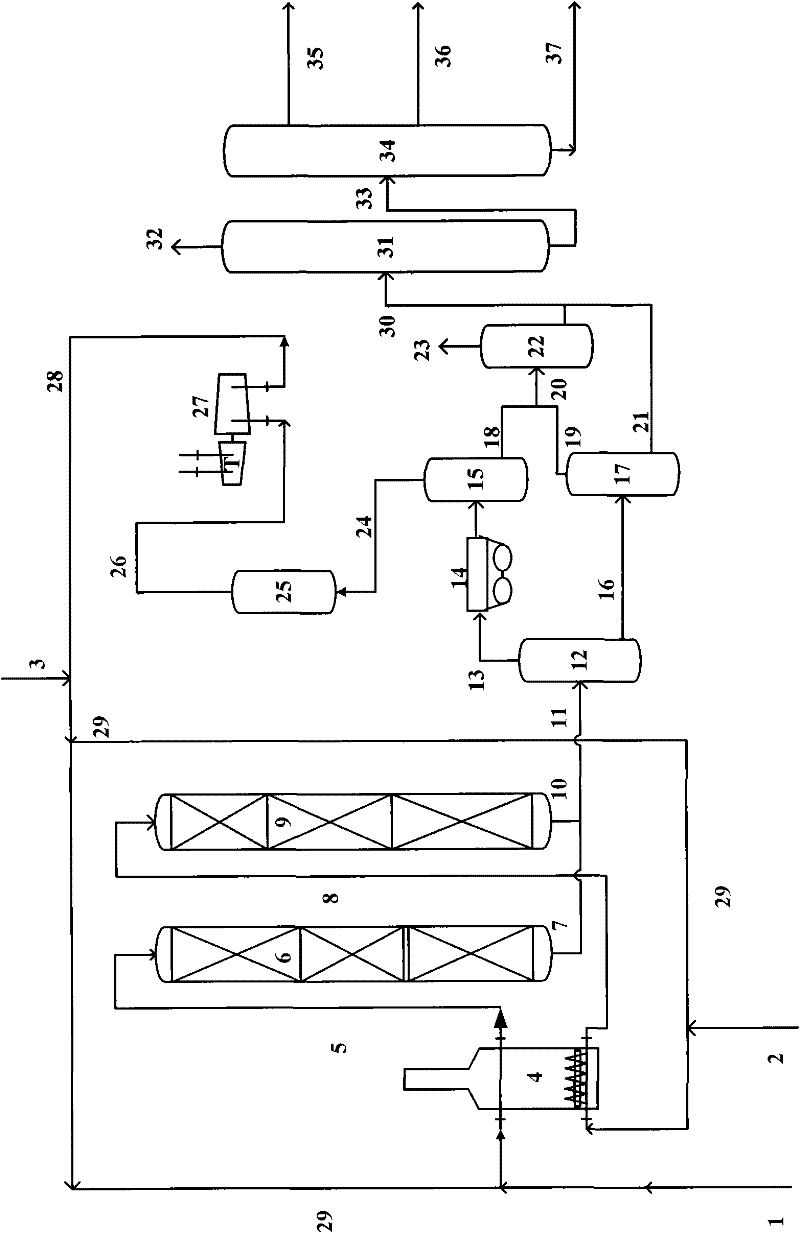

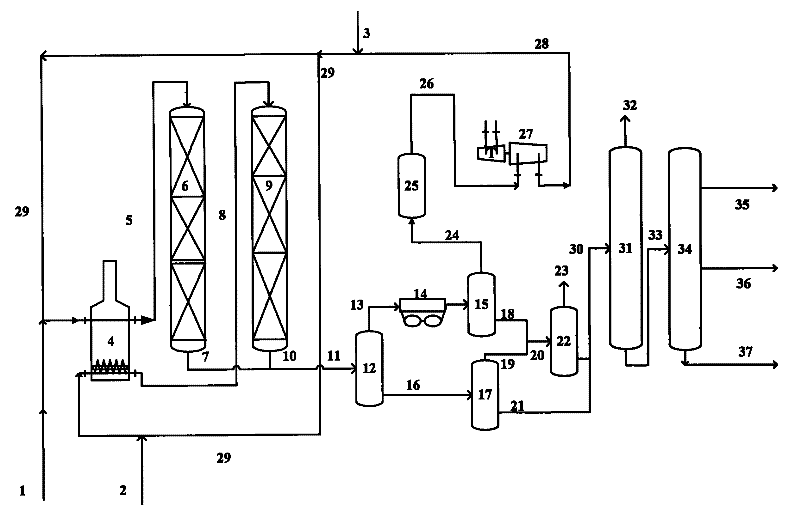

Embodiment 1

[0030] The wax oil raw material in Example 1 is a mixed oil of coking wax oil and heavy straight-run wax oil, and the diesel raw material is a kind of inferior catalytic diesel raw material. The properties of the raw material are shown in Table 1. The embodiment is carried out on a 3L fixed-bed medium-scale hydrogenation test device equipped with two reactors and a common hydrogen system. The commercial grade of the catalyst combination used in the wax oil hydrotreating reactor is RG-10A / RG-10B / RVS-420 / RN-32V, and the filling volume ratio is 7:8:25:60. The combined commercial grade is RG-1 / RS-1000 / RIC-2, and the filling volume ratio is 9:60:31. After the catalyst is vulcanized and stabilized, the raw material oil is processed. The reaction products obtained in the two reaction zones are separated in the same post-separation system, and the hydrogen-rich gas obtained is returned to the reaction zone. The obtained liquid products are fractionated to obtain naphtha and diesel oil...

Embodiment 2

[0037] The wax oil feedstock in Example 2 is a straight-run wax oil with relatively good properties, and the diesel feedstock is a mixed oil of catalytic diesel and straight-run diesel. The properties of the feedstock are shown in Table 3. The properties of the two raw materials are relatively good, and a lower reaction pressure and a higher volumetric space velocity can be set. The embodiment is carried out on a 3L fixed-bed medium-scale hydrogenation test device equipped with two reactors and a common hydrogen system. The catalyst combination used in the wax oil hydrotreating reactor is commercially designated as RG-10A / RG-10B / RVS-420 / RN-32V, and the filling volume ratio is 5:5:40:50. The catalyst combination is used in the hydrogenation reforming reactor The commercial grades are RG-1 / RS-1000 / RIC-2, and the filling volume ratio is 7:63:30 respectively. After the catalyst is vulcanized and stabilized, the raw material oil is processed. The reaction products obtained in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com